Top side rail is structural component running longitudinally along top sides (left and right) of the container between the end frames of the shipping container. This article briefly explains the top side of the shipping container. Top Side Rails are welded to several components of shipping container. They are corner fittings, corner posts, roof panels, door header extension plates, front and rear header extension plates, corner protection plates and side panels. Lashing rings are welded to each bottom and top side rail at corresponding recessed area of side wall. And some high cube containers can be seen on high cube stripes on exterior.

Table of Contents

Top Side Rail – Main types explained

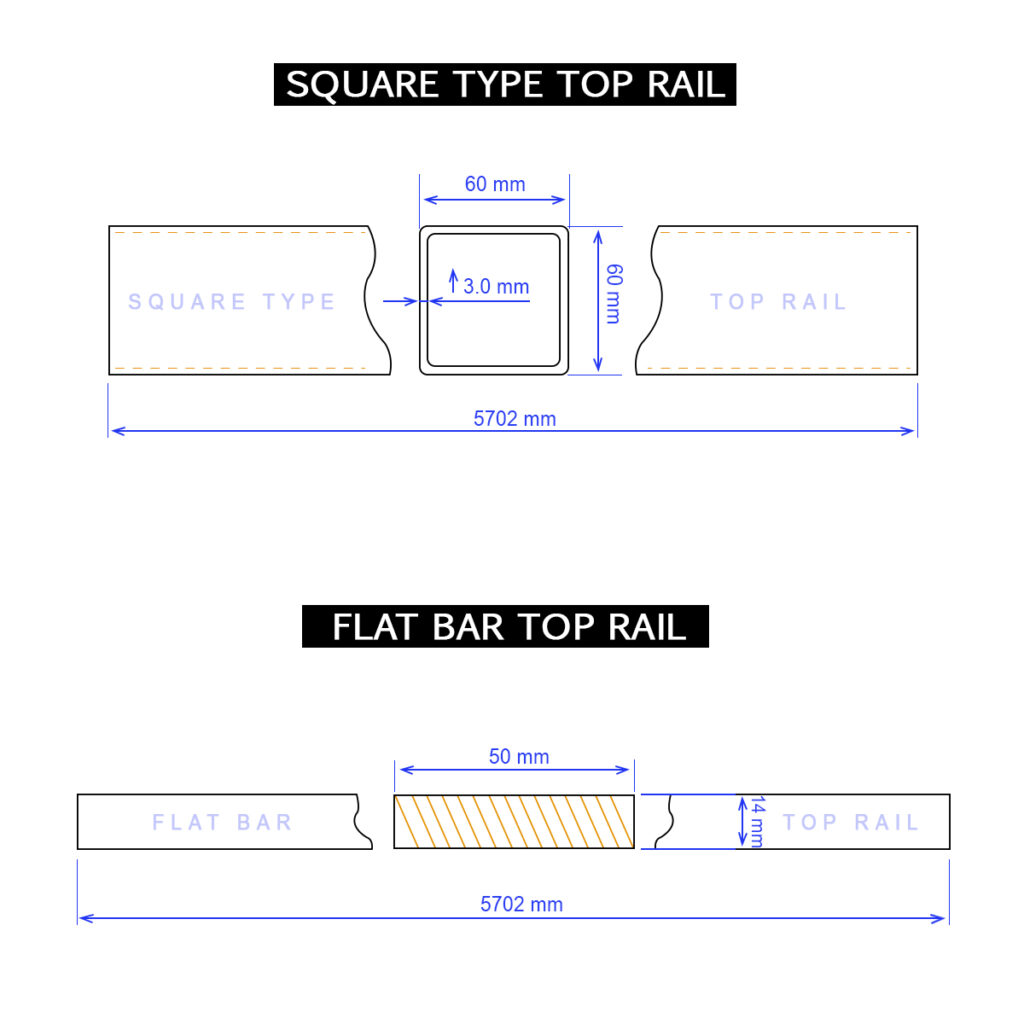

Top side rails are made of corten steel; In the industry there are two types of top side rails.

- Square Type Top Rail

- Flat Bar Top Rail

Square Type Top Rail

Tube Type Top Rail made of SPA-H Corten-A steel ,

Dimension is height 60mm, width is 60mm, and the thickness of 3mm.

Square Type Top Rail known as tube type top rail, tubular type top rail, box bar top rail.

Flat Bar Top Rail

Height is 14mm, width 50mm and thickness of 12mm.

made of SPA-H Corten-A steel.

Shipping Container Top Side Rail Dimensions

Square type top rail thickness is 3.0mm and height 60mm, and width of 60mm.

Flat bar top rail type, height is 14mm, width 50mm and thickness of 12mm.

What are the damages ?

Holes, cuts, bend, bow, tear, broken, cracks or dents on top rail known as damages.

How to measure Top Side Rail Damages

In these videos explains how to measure deformations of Top Side Rail as per IICL

Top Side Rails Deformations

From the outside of the container position the reference line on the top of side rail as far as practical from damage area, Reference line should pass over the deepest point of deformation, IICL tolerances for outward deformation on side faces of the top side rail is 30mm. If deformation exceeds 30mm top side rail is considered as ” damage “

Top Side Rail Outwards Deformation- “Out of ISO”

From the outside of the container place a 10mm thick spacer on the side faces of the top corner fittings. Position the reference line on top of the spacers, reference line should be positioned over the farther point of deformation. IICL damage tolerance for outward deformation on side surfaces of top side rails are 10mm. If the outward deformation exceeds 10mm thus touching the reference line, top side rail is considered as ” damage “

Top Side Rail Upwards Deformation- “Out of ISO”

From the outside of the container place a 5mm thick spacer on the upper faces of the top corner fittings. Position the reference line on top of the spacers, reference line should be positioned over the highest point of deformation. IICL damage tolerance for upwards deformation on top side rail is 4mm. If the distance between the reference line and the top rail is less than 1mm, top side rail is considered as ” damage “

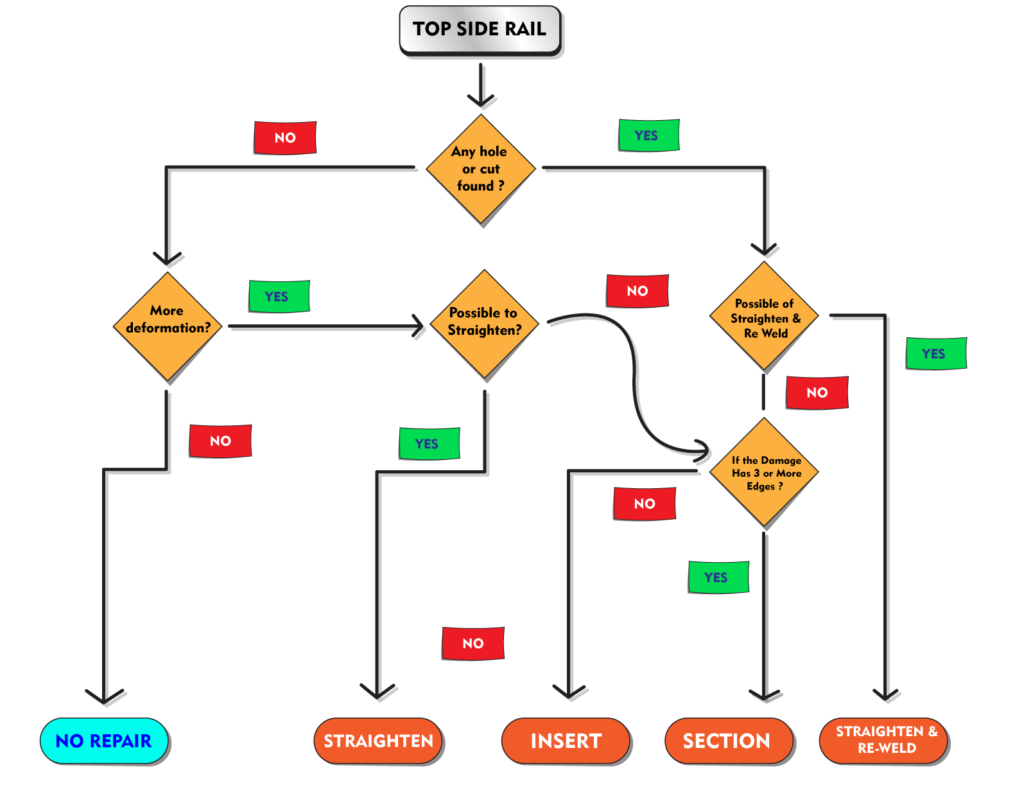

Shipping Container Top Side Rail Repair Methods

Straightening, straightening and weld, welding, sectioning, sectioning, replacement

Top side rail repair decision maker indicates “more deformation” which depends on reach owners criteria.

Example :- According to IICL any deformation ( bend,bow,dent ) if more than 30mm deep action should required.

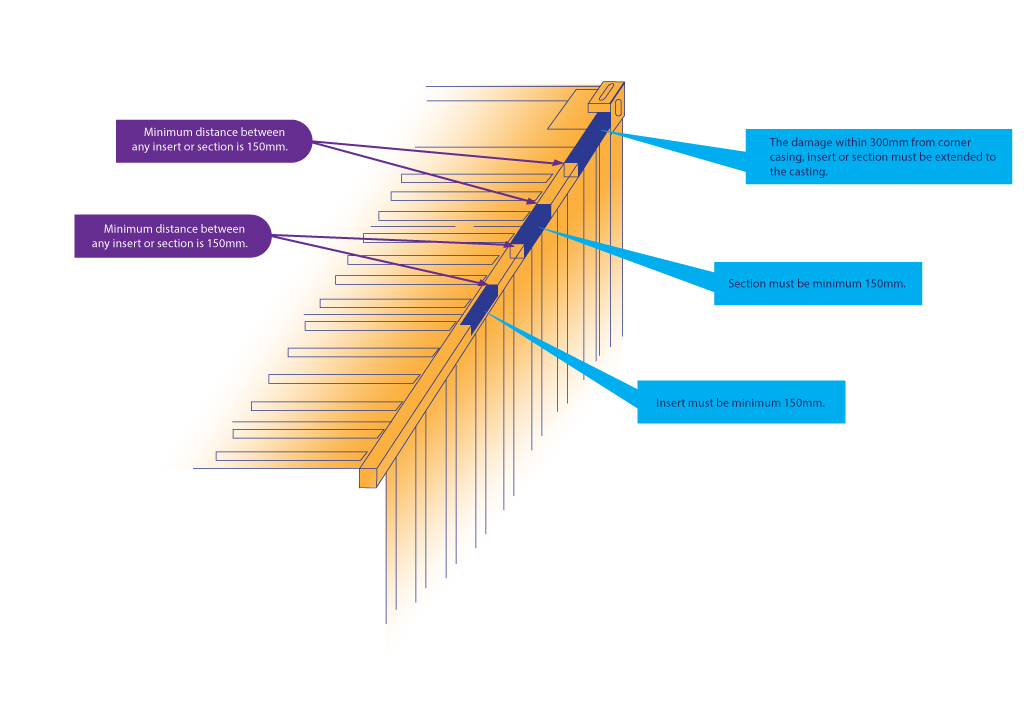

4 Rules of Repairing Square Type Top Side Rail

- Section or insert must be minimum 150mm in length

- If a section or insert ends within 150 mm of another rail weld, it must be extended to that weld..

- The damage within 300mm from corner casting; insert or section must be extended to the casting.

- Minimum distance between any insert or section is 150mm.

Note – No more than 2 mm joint gap between adjacent surfaces, overlapping patches can be welded only to the upper surface. No insert permitted to flat top rail.

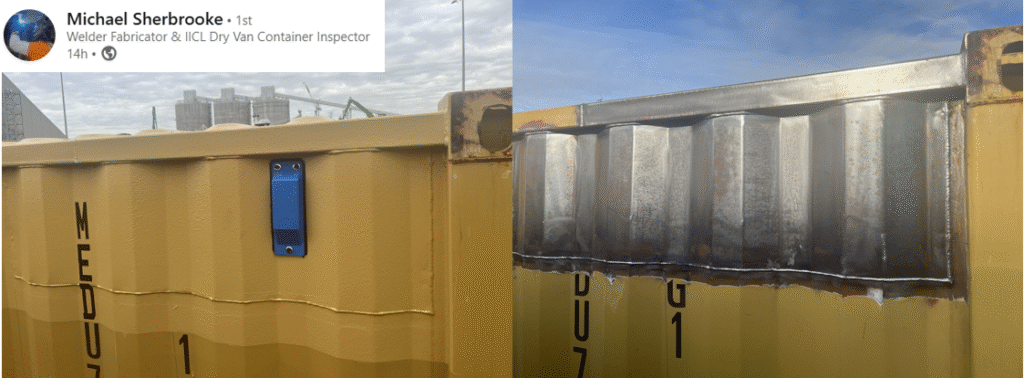

Damage Types examples

Disclaimer

This article does not represent IICL in any manner it has created for knowledge & education for shipping and container industry.

What You Should Know About Bottom Side Rail

Disclaimer: The views expressed by the authors in this article do not necessarily reflect the views of CONTAINER SURVEYOR. Data and charts, if utilized, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and CONTAINER SURVEYOR do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.