Intermodal transportation is facilitated using shipping containers allowing transport by different modes of transport such as ship, truck, and rail. The reasons behind choosing shipping containers to transport goods around the world are durability, weather resistance, security, standardization, and modifiability.

Table of Contents

01. What is the shipping container damage?

Basically, ‘damage’ can be known as physical harm that impairs the value of the container. Damage can happen due to one or a few improper handling or use events that may affect the container’s structural integrity, dimensions, water tightness, light tightness and certification requirements.

In the shipping container industry, abusive or improper actions are also known as damage conditions per each shipping line’s criteria. Moreover, some repairs can be measurable with specific limits, and some may not.

Shipping Container Measurable Damages

- Front corner post dent

- Floorboard gouges

- Roof panel dent

Shipping Container Unmeasurable Damages

- Interior strong odour

- Infestation

Shipping Container Wear and Tear Damages

Wear can be known as a condition and happen of the normal container deterioration, and the owner is accountable for carryout repairs and actions.

Ex: – corrosion, paint failure, destruction of markings

Shipping Container Improper Repairs / Non-Conforming Repairs

Improper repairs or non-confirming repairs of shipping containers falling under the damage category. Suppose repairs are done by the wrong method. In that case, the repairs do not meet specific technical requirements, poor quality, and substandard materials used are considered damaging because this condition is risky for human life and cargo in transportation and handling.

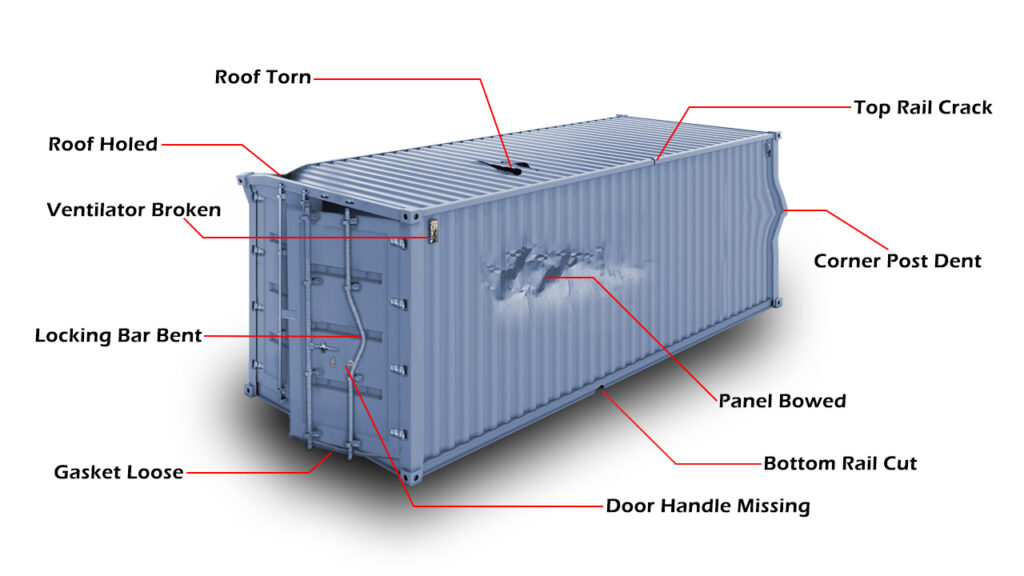

Damage types

Before selecting a particular container, every shipper/consignor looks for a container condition suitable for their cargo. Also, the shipper can select a suitable container from the designated depot.

On some occasions, shippers are reserved the container from depots or arrange a representative/surveyor to check the container or else the haulier must select the container based on the shipper’s requirement.

Shippers consider various things in the container, such as structural damage free, clean, free from wind and watertight, no improper repairs like sharp edges interior side which there may be damage happened to the cargo etc.

Shipping container damage examples: –

Bent – a deflection in a structural component that causes the component to change direction from its original design. ( Locking Bar Bent )

Bowed – a gradual deformation of the entire length of the component in a direction perpendicular to that length.

Dent – a localized depression in a panel or structural member made by pressure or an impact that causes an abrupt change in the shape of a component over a limited area of the component.

Broken – fractured into two or more separate pieces.

Cracked – having a break that penetrates the entire thickness of the material. ( Side Top Rail Crack )

Cut – separated throughout the entire thickness of a material along a sharp edge.

Torn – pulled apart by ripping or rending through the entire thickness of the materials.

Holed – perforated through the entire thickness of a component.

Bulged – a curved mass on the surface of a component; bulge happens inside or outside of the component.

Loss of removable components (missing components)

Loose – component is not tightly in place.

Most of the time, the above damages can be identified as structural damage. However, if the interior condition is not fit for cargo, and can be damaged during the delivery, also known as damage.

If the container remains debris, packing, dunnage, lashing materials, stains, tape or glue attached to the surface, soil, sand, heavy dust, mud, persistent odour, protruding nails and all cargo-related labels, the container is not suitable for release because sometimes containers can be contaminated with pests or sometimes odour.

For instance, a container that previously carried food items can pass on the odour to the next cargo item, or protruding nails can damage the cartons.

02. When and where can damage happen?

Multiple parties and locations handle containers during their journey. And the damage can happen to any of these locations.

- At the container depot/container yard.

- While loading empty containers for shipment from the container yard.

- The time of the local trucker moving empty containers to the shipper’s premises.

- While cargo is loaded onto an empty container from the shipper’s warehouse.

- During the transportation of laden containers to the origin port.

- While handling the laden container at the origin port.

- At the time of loading the laden container onto the vessel.

- Container onboard

- While handling the transhipment port / during stuffing and de-stuffing in transhipment.

- While discharging the container at the port of discharge

- While handling the container in the discharge port.

- While transporting the laden container to the consignee’s premises.

- While cargo is being destuffed consignee’s warehouse.

- At the time of returning the empty container to the designated depot.

03. Reasons for shipping container damages

In this article, we will discuss different occasions and reasons why damage causes happen to the shipping container.

How damages can happen in Shipping Container Yard

A shipping container depot or yard accommodates containers before they’re released for consignments or shipped to the port for evacuation (backload). During the operation, there are chances to damage the containers inside the yard.

While loading or unloading time

Usually, container depots are used to unload and load the containers by heavy lift equipment such as forklift reach stacker, side handler, and top handler, faults of them cause damage to the containers while loading and unloading time.

Poor handling of heavy lift equipment

- Inexperienced heavy lift equipment operators cause damage to the containers during handling.

Shifting container from stack to stack or stack to repair workshop (Poor Handling)

- Sometimes, containers shift from the present stack to another stack (reservation), or containers are placed in the workshop and relocated after repairs. At that time also, containers can be hit by another container.

Accidents by handling heavy lift equipment or trucks

Usually container yards are busy in everywhere for loading and offloading, in this cases , hit by a moving vehicle causes damage to the containers and needs necessary repairs required to make the container sound condition.

Stacking on unstable ground / stacking over height and uneven stack

When operators stack containers on uneven ground, there’s a real chance that those containers might collapse or accidentally tumble down. It’s not just a matter of careless handling; it also points to less-than-ideal yard conditions.

To keep things safe and running smoothly, it’s crucial for operators to follow the best practices when stacking containers. Regular checks of the yard conditions should be done to catch and fix anything that could make things unstable. This way, we can make sure we’re creating a safe and efficient workspace for everyone.

Natural disasters / Acts of God

Any occurrence that cannot be predicted or prevented by humans is unexpected. Examples of common natural catastrophes include cyclones, volcanoes, earthquakes, floods, and tornadoes, these occurrences will cause harm to containers.

How damages can happen during road transportation

Usually, shipping containers are transported by a haulier, and they pick up the empty container from the container depot and deliver it to the shipper’s premises (warehouse). From there, the laden container is delivered to the seaport. The destination consignee’s haulier picks a laden container from the discharge port and delivering to the consignee’s premises to de stuffed the goods. After they return the empty container to the nominated container yard, damages can happen during this transportation.

Due to a road accident

- High speed, poor road conditions, bad weather conditions, and driver fatigue may cause accidents on the road and simultaneously affect containers.

Bad stowage by the shipper

- If cargo is not properly packed, improper and insufficient lashing is the biggest cause of physical damage.

Properly container not locked in the trailer (castings)

When the operator places the container onto a trailer driver must securely attach a container with four twist locks. If drivers fail or it’s not properly attached to a container, the container can be dropped from the trailer during transportation.

Poor trailer/vehicle condition

Some trucks and trailers need to be better maintained, and more faults are unsafe for transporting the containers. This is also known as a reason for how containers can be damaged

How to damage containers at the consignee or shipper’s premises

Cargo not properly packed

- This will affect the stability of the cargo, which can damage the containers in different ways.

Improper and insufficient lashings used for secure cargo

- Reason for proper lashing and sufficient lashing used for restricting the movement of cargo, cargo movement causes damages to the side ends and roof of containers.

Lack of knowledge of handling cargo

- Inexperienced and needing more knowledge to prevent damage to the container while stuffing and during the delivery.

Negligence of forklift operators

- If the forklift is not properly operated, there are more chances for happening physical damage to the container.

Overloading

- Overloading causes damage to the container floorboard and its risk to cargo as well.

Incorrect weight distribution

- Incorrectly declared weights can result in container collapse, personal injury, and damage to equipment.

How to damage containers at the port and during transit port

Loading port & discharging port

During the unloading time

- In the terminal, containers are unloaded using gantry cranes, and containers can be damaged at that time.

- Shifting container from stack to stack

- While shifting stack to stack, another container can damage and hit containers.

Road accidents

- High speed or being hit by moving vehicles can cause damage to containers.

While loading containers

- While loading containers vessel to the vessel by gantry cranes, containers can be damaged the container by hitting objects or hit by another container.

Natural disasters

- Floods, hurricanes, blizzards, earthquakes, and ice storms are the natural calamities that have the biggest effects on the transportation Each of these natural disasters creates hazardous driving conditions and, in some situations, can entirely wash away roads or render them impassable.

Transit Port

- During loading and offloading time

- Destuffing time

- Shifting time

How to damage containers at a vessel onboard

Collapse/fall of

Fire onboard

04. Who is responsible for the container damage?

Throughout an international shipping route, shipping containers are handled by many different entities, shipping container damage can happen at any point during transportation, and without proper investigation/survey, nobody can pass the liability to other parties.

Ex: – while transporting the laden container from the shipper’s premises to the origin terminal, the accident happened on the road. We can assume the responsible party should be the transporter since the container was damaged under the transporter’s custody. However, after investigating the reason, the result of damages happened due to the “bad stowing” in this scenario shipper is responsible for negligence.

- Container depot/container yard – negligence by the depot, weather conditions or collapse etc., is for the account of the depot.

- Trucker/Hauler – negligence during transportation, such as drunk driving, traffic violations etc., the haulier recovers the repair cost.

- Consignor/shipper – negligence by the shipper is accountable for damage costs.

- Consignee – negligence by the consignee, such as improper de-stuffing and improper handling, always under the consignee account

- Terminal – This can be the origin, transhipment or destination terminal, and negligence by the terminal is for the account of the terminal.

(Above information may vary based on the terms and conditions/agreements of each party)

05. How to avoid shipping container damage? (Damage Prevention Measures)

How to minimize container damage in Shipping Container Depot

Loading or unloading / Poor handling of heavy lift equipment

Faults in handling heavy lift equipment cause damage to containers while loading, unloading, and handling time. Therefore, periodic maintenance and services should be very important to avoid physical damage; Also need to provide a checklist (heavy lift equipment condition) to the heavy lift equipment operator before starting the work on the equipment to start the yard operation.

Inexperienced heavy lift equipment operators cause damage to the containers during yard operations; therefore, they need good training. If they are not experienced, they need to work for some duration with experienced operators to get senior’s knowledge of situation handling, methods etc.

Shifting container from stack to stack or stack to repair workshop (Poor Handling)

- Offloading or placing the containers in the correct locations and categorizing them will minimize the shifting. Unloading damaged containers near the workshop is easy to arrange them to the workshop with less time and shifting.

Accidents by handling heavy lift equipment or trucks

- To avoid accidents inside the yard, the safety team must provide safety instructions before the gate in any vehicles, use signboards to avoid traffic, arrange necessary gaps between each container stack, and make strategic plans for rush hours.

Stacking on unstable ground / stacking over height and uneven stack

All the time, containers should be offloaded on a flat surface and properly stacked, and the proper height of stacking containers can avoid the collapse of shipping containers.

How to avoid damages can happen during road transportation

Due to a road accident

- Truckers/hauliers must take all precautions to avoid road accidents by providing a list of instructions while they are transported in either empty or laden containers.

Ex: – high speed, mobile phones use while driving, parking in unnecessary locations.

Properly container not locked in the chassis (castings)

- Retractable twist locks are supports to tighten the container on the chassis, and the driver must ensure the twist locks are properly locked with the container before starting the transport.

Poor trucks and chassis condition

- Hauliers must carry out periodic maintenance and services without fail. If any truck or trailer is not suitable / not safe or is in accident condition, the haulier must repair them or stop those vehicles until it’s fit to transport the containers.

How to avoid damage containers at the consignee or shipper’s premises

Cargo not properly packed / incorrect type of container used.

- When packing cargo, you need to ensure that the cargo is properly checked and allocate someone after packing to check the quality of packing. You must select the container time based on the weight and volume to avoid damage to the cargo and container.

Improper and insufficient lashings used for secure cargo

- Ensure that the lashing and dunnage material and methods are sufficient to restrict the movement of the cargo within the container or employ the services of a cargo surveyor.

Lack of knowledge of handling cargo

- Employ the services of a cargo surveyor who can recommend the best practice for securing your cargo.

Negligence of forklift operators

- It would help if you used experienced professional forklift operators, and supervisors have to supervise them occasionally.

Overloading

- Ensure that all container weight limitations are met as per the markings on the container or request the container based on cargo weight.

Incorrect weight distribution

- Ensure that you always follow the SOLAS VGM requirements.

How to avoid damage containers at the port and during transit port

During the loading and unloading time or shifting containers

- Experienced gantry crane operators utilized for work or educate the crane operators on proper handling, work on a shift basis and considerable rest.

Road accidents

- Set a speed limit inside the terminal, educate the locations before the gate in the vehicles, safety team must control the traffic.

Natural disasters

- Receive and act on the latest weather forecasts to avoid severe weather.

How to avoid damage containers at a vessel onboard

Collapse/fall of

- Receive and act on the latest weather forecasts to avoid severe weather. Check for container casting conditions, stack containers symmetrically, and do not overload containers. Also, check that lashings have been applied correctly by stevedores. Crew should regularly check and tighten lashings as required. The condition of lashing equipment should be monitored, and any damaged or worn gear should be replaced.

Fire onboard

- Comply with IMDG Code regulations for segregation/heat sources, avoid storing near heated regions Poor stowage by the crew.

- Take necessary precautions if any hot work is being carried out onboard.

Disclaimer: The views expressed by the authors in this article do not necessarily reflect the views of CONTAINER SURVEYOR. Data and charts, if utilized, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and CONTAINER SURVEYOR do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.