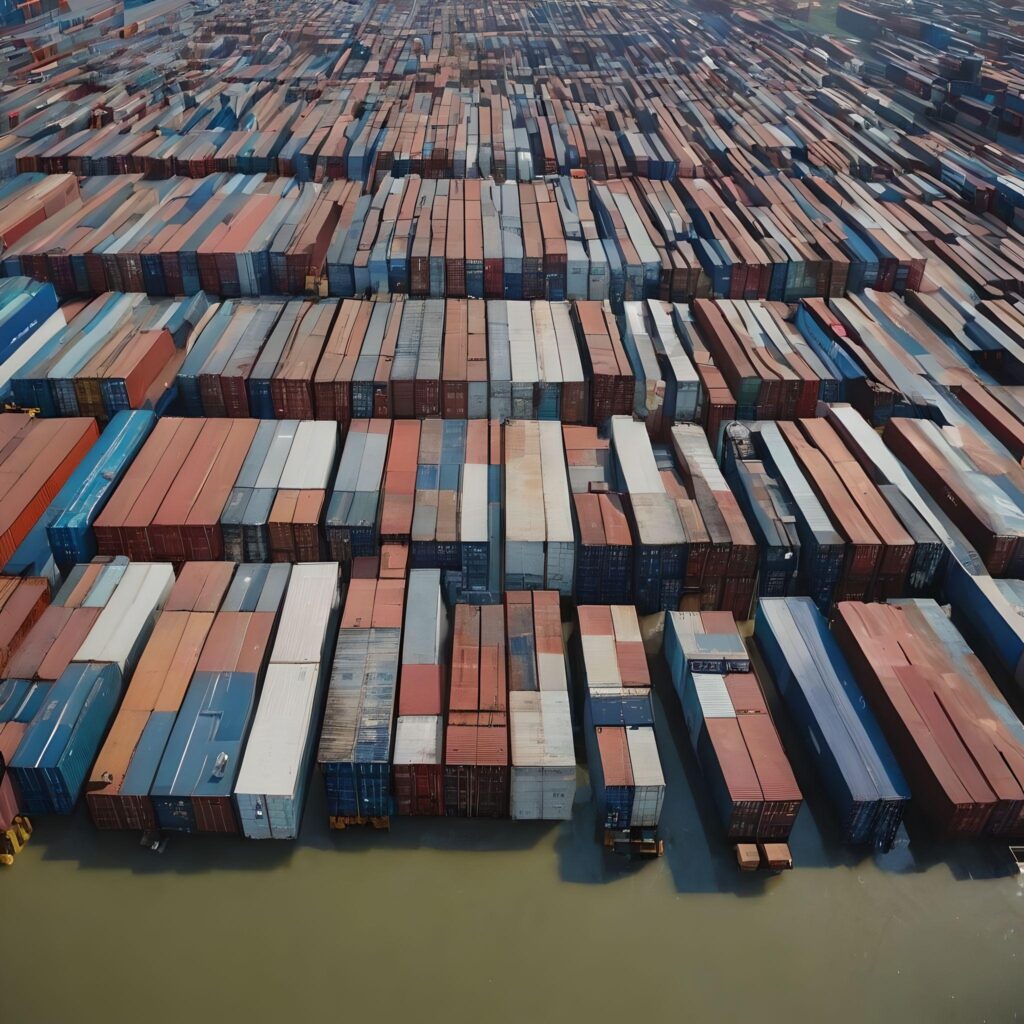

Shipping container damages arise from the dynamic operations within container yards, depots, or terminals, where an array of activities such as storage, loading, unloading, and transportation take place. These bustling hubs are prone to accidents and incidents, posing a constant risk to the integrity of the containers involved.

Table of Contents

The factors can contribute to damages in shipping container yard

- 1. Handling Equipment Accidents and Collisions

- 2. Containers Stacking Issues

- 3. Weather Conditions & Natural Disasters

- 4. Incorrect Loading and Securing

- 5. Human Errors

- 6. Security Incidents

- 7. Infrastructure Problems in the Yard

Shipping Container Damages Resulting From Handling Equipment Accidents

This can be identify the main factor of Shipping Container Damages at the container yard and this can be on 2 ways.

– From Handling Equipment or operator’s side

– From Shipping Container Trucks or driver’s side

01. Handling Equipment / Shipping Container Trucks Collisions or Accidents

To gain a comprehensive understanding, these factors can be categorized into four main groups, encompassing human factors, equipment/trucks related issues, operational challenges, and environmental influences.

1.1 Operator-related / Driver-related Issues

An operator, defined as an individual responsible for operating equipment like Reachstackers, Container Stackers, and empty or loaded container handlers, may contribute to damages. Issues can arise from the operator’s end due to various reasons,

- Operator Errors

- Lack of Training

- Supervision Issues

- Inadequate Training and Supervision

Issues can arise from the driver’s end due to various reasons,

- Poor Driving Habits or Impatience

- Lack of Training

- Distractions

- Fatigue

- Lack of Awareness

1.2 Equipment-related Factors / Mechanical Issues

Equipment-related difficulties arise for operators in the course of our daily activities. Important elements include blind spots, equipment problems, and mechanical breakdowns.

From the Driver’s Perspective, we navigate a complex landscape where vehicle malfunctions pose significant risks. From brake failures to steering system problems, transmission malfunctions, tire issues, suspension system failures, engine malfunctions, exhaust system problems, and electrical system failures.

1.3 Operational Challenges

Navigating through a container yard comes with its own set of challenges.

- Bustling high traffic areas

- Congested yards

- Crucial intersection points

- Container Inspection delays

1.4 Environmental Influences

Sometimes, things are out of our hands and the equipment’s control. Take weather and environmental conditions, for example. They’re in a category of their own and can affect how we handle containers. Mother Nature plays a part, and we’ve got to adapt to keep things running smoothly.

2. Containers Stacking Issues

Incorrect stacking in a shipping container yard can spell trouble. It’s not just about dented or bulge in container boxes; it can lead to financial losses, safety hazards, and delays.

Check – Stacking Shipping Containers: A Comprehensive Guide

The ways in which incorrect stacking can cause container damages.

01. Weight Distribution and Stability

Placing heavy containers on top of lighter ones can lead to structural damage in the lower containers.

02. Improper Securing

Stacking containers without following a proper sequence can affect stability. For example, placing an empty container on top of a fully loaded one may lead to stability issues.

Containers should be stacked in a stable and interlocked manner to prevent them from shifting or collapsing.

03. Inadequate Support

Placing containers on uneven or unstable ground can lead to tilting or leaning, causing structural damage.

Weather Condition & Natural Disasters Causes Damages

Extreme weather in a shipping container yard poses significant challenges, affecting operations, infrastructure, and personnel. These adverse conditions, like storms, hurricanes, snowstorms, and heatwaves, can strike unexpectedly. Geographical location plays a role. also Natural disasters can cause significant damage to shipping containers in container yards.

Weather Conditions

Wind – Strong winds can cause containers to fall over, resulting in structural damage. Additionally, debris carried by high winds can impact the containers, causing panel dents and other damages.

What are the wind speeds a shipping container can withstand? – In accordance with rigidity test standards, a shipping container, when properly anchored, can withstand wind speeds of up to 180mph. However, altering the container for modifications can compromise its structural integrity, thereby reducing its ability to withstand high wind speeds. It’s worth noting that loading contents into a container contributes to its resilience against stronger winds.

Heavy Rain, Snow, Hail & Blizzards – Continuous exposure to heavy rain or melting snow can result in water ingress into containers. (Damaging goods inside)

Heavy Rain, Snow, Hail & Blizzards reduce visibility, making it challenging for operators to handle containers safely and increasing the risk of accidents.

Temperature Extremes (Heatwaves and Cold Waves) Thermal expansion of container materials can lead to the same effect impacting the interior and causing structural damages, with the possibility of fire as well.

Dust and Sandstorms – Sand or dust particles carried by strong winds during storms can lead to abrasion and surface damage on container exteriors and Sandstorms in coastal areas can carry salt, contributing to corrosion on container surfaces.

Droughts – Prolonged droughts can lead to ground shrinkage, potentially affecting the stability of container stacks and foundations

Natural Disasters

Hurricanes/Typhoons/Cyclones – Strong hurricane or typhoon winds causes falling containers, causing structural damages.

Tornadoes – Tornadoes generate extremely strong winds that can causes heavy damages to containers.

Earthquakes – The shaking of the ground during earthquakes can lead to container movement and fall down from stacks causes structural damages.

Floods – Floodwaters can submerge containers and related damages.

Incorrect Loading and Securing

Insufficient Training: stands out as a key factor contributing to mishandling in container yards is the lack of proper training for forklift operators, crane operators, and other handling equipment experts. Imagine a scenario where these crucial team members are not equipped with the necessary skills causes heavy damages for containers.

Lack of Experience: Novice operators or those unfamiliar with handling procedures may find themselves grappling with the intricacies of container management, leading to a host of issues.

Handling Procedure Hurdles: Even with the best training, executing proper handling techniques can be challenging. Individuals who are not well-versed in the nuances of handling procedures may find it difficult to navigate the complexities of container movements. This can result in inefficiencies, delays, and increased risk of accidents.

Exceeding Weight Capacities: Is the one of the riskiest scenarios involves attempting to handle containers that exceed the weight capacity of the equipment in use. This not only jeopardizes the safety of the personnel but also poses a significant threat to the integrity of the handling equipment. Accidents and equipment failures become likely outcomes when weight capacities are pushed to the limit.

How Human Errors Cause Container Damages

Several factors contribute to human errors in a container yard setting. Identifying these factors is crucial for implementing preventive measures and improving overall safety. below mention factors that can lead to human errors in a container yard.

Insufficient Training & inexperience : Insufficient training and inexperience have a negative impact on container yard operations. Lack of proper training or experience for operators and other handling personnel can lead to errors during operations.

Poor Communication : shipping container yard damages or container accidents is a type of human error known as miscommunication. Inadequate communication between crane operators and ground personnel can result in misunderstandings, leading to accidents during loading or unloading operations. Additionally, failure to adhere to signaling protocols can contribute to container accidents.

Fatigue, Stress & Time Pressure : Long working hours, tight schedules, and high-pressure conditions can cause fatigue and stress, weakening concentration and capacity for decision-making.

Lack of Focus : Distractions, surrounding activities, or other factors, can divert the attention of operators, increasing the risk of errors.

Neglecting Safety Protocols & Poor Supervision : Neglecting safety protocols and experiencing poor supervision are critical challenges in container yard operations. Failure to adhere to established safety procedures can result in unsafe practices, leading to accidents and container damage. Additionally, inadequate supervision is a significant factor contributing to issues within the container yard.

Security Incidents

Theft and vandalism are key concerns, but their prevalence depends on the region and the security levels of the container yard. Maintaining a consistently high security level is essential to prevent these issues. Additionally, minimizing unauthorized entrance significantly reduces security risks in the container yard.

Infrastructure Problems in the Yard

Poor Layout Design : Insufficient planning in the design phase may result in a poorly laid-out yard, leading to congestion, and increased risk of accidents.

Condition of the yard : Some container yards are not well-maintained, with uneven asphalt surfaces contributing to structural damages and an increased risk of containers falling. The waviness of the ground exacerbates the potential for accidents and damages within the yard.

Outdated Equipment : The usage of outmoded handling equipment, such as cranes or forklifts, can lead to slower operations, higher maintenance costs, and worse efficiency.

Learn about – Shipping Container Repair Procedures

Disclaimer: The views expressed by the authors in this article do not necessarily reflect the views of CONTAINER SURVEYOR. Data and charts, if utilized, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and CONTAINER SURVEYOR do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.