Table of Contents

Most shipping containers come with two doors at the rear, commonly known as shipping container doors. These are typically seen on container types such as dry containers, reefer containers, open-top containers, and hard-top containers. However, some containers are designed with more than two doors, such as open-side containers and double-door containers, which allow easier access from multiple points. On the other hand, certain container types do not have doors at all, including half-height containers, platform containers, and flat rack containers.

To learn more about the different types of containers and their uses, you can read our article “17 Shipping Container Types You Should Know About”

Shipping container doors play a key role in providing accessibility, protecting cargo, and displaying vital container information such as weight limits and identification details. These doors help determine how much weight can be safely loaded into the container. Unlike in the past, modern innovations have significantly improved efficiency and safety in container design. A great example is the reefer container, which is specially designed to transport temperature-sensitive cargo, ensuring products remain in optimal condition throughout the journey.

The Evolution of Shipping Container Doors

These days, efficiency and safety are priorities when designing shipping container doors. They come in different shapes and sizes including roll-up doors, swing doors, and even refrigerated doors for temperature-sensitive cargo. These innovations have completely changed the sector and improved efficiency, safety, and speed of cargo transportation.

For instance :- open-side doors efficiency ad safe levels are high.

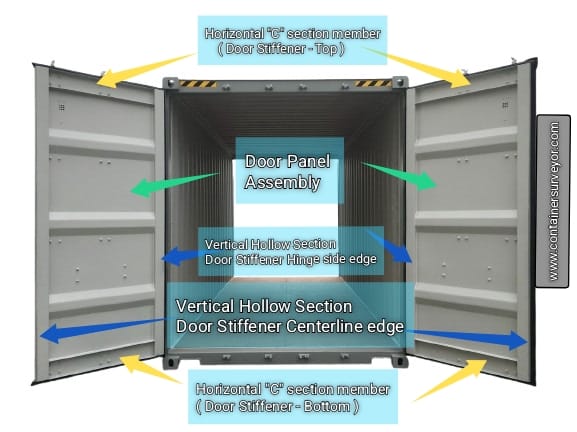

Design of Container Doors

The body is consisted two vertical hollow sections and two horizontal “C” section members are joined and frame is infilled with Corten steel corrugated steel panels. 4-5 hinges are placed in perfect alignment and door hinges act as pivot points on the door, allowing free rotational movement of 270o degree opening which allow the doors to swing back against the container side panels.

The entire door frame is known as the door frame assembly, which is constructed with several stiffened edges for strength and durability. These include the Door Stiffener centerline edge, Door Stiffener hinge Side Edge, Door Stiffener bottom edge & Door Stiffener top.

On a standard shipping container, the right-side door is fitted with a full gasket around all four sides, fixed using a gasket retainer.

The left-side door, however, only has gaskets on the top, bottom, and the door frame side. There is no gasket on the vertical edge where the two doors meet. This design is intentional because when closing the container, we first close the left door and then close the right-side door afterward. The vertical gasket on the left edge of the right-side door seals the center gap between the two doors. This ensures a proper weather-tight and secure closure once both doors are locked.

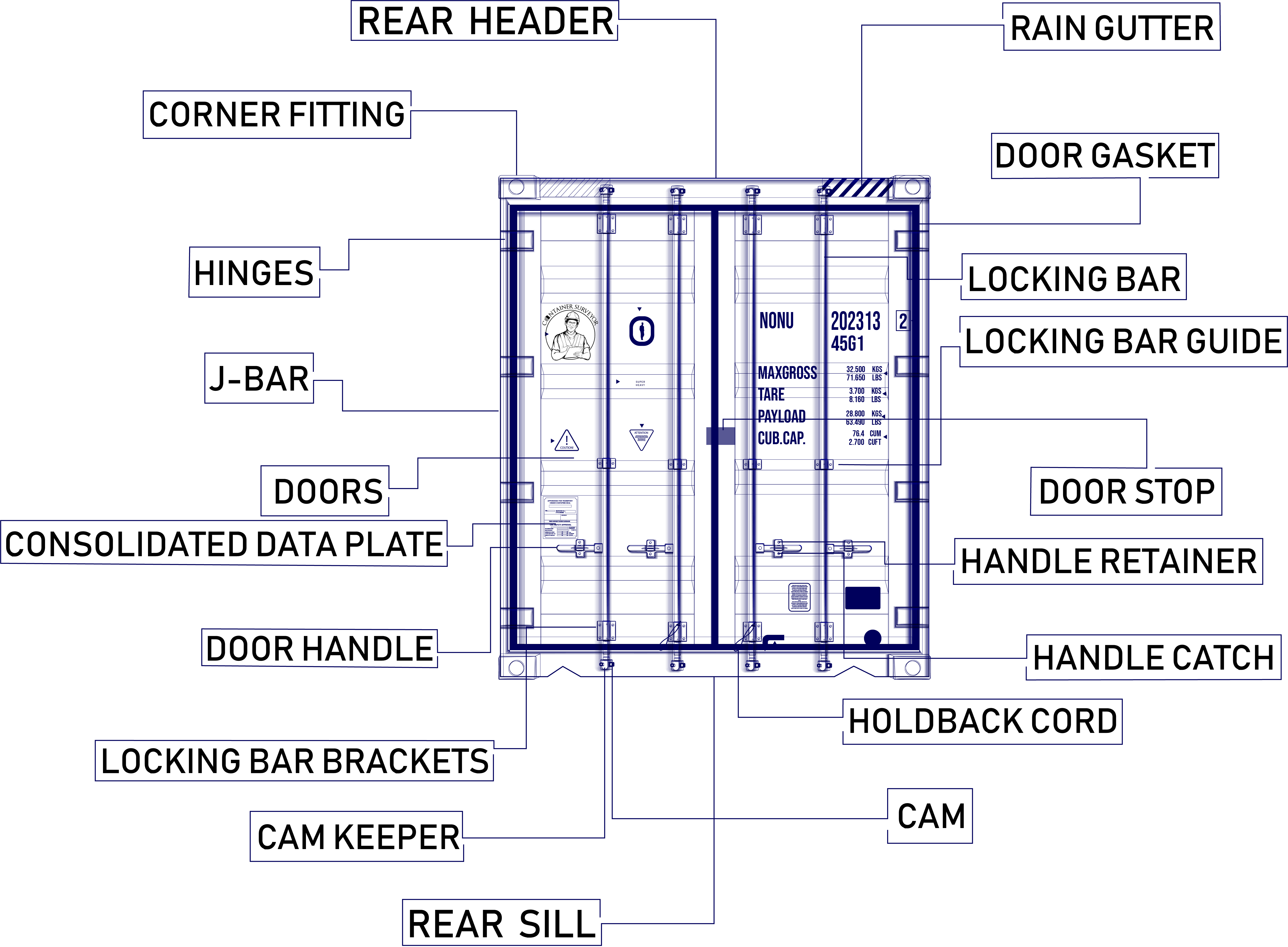

On the exterior side of the container, several shipping container door components can be seen. Each of these parts plays a vital role in the door operation, including smooth opening and closing, securing the doors tightly, and ensuring the container is properly sealed during transport. These components include,

| Door Component | Description |

|---|---|

| Door Handle | Provides leverage to rotate the locking bars and operate the door opening and closing |

| Door Handle Retainer / Door Handle Catch | Secures the handle in the locked position, preventing any movement that could break the seal. |

| Locking Bar Cam | Engages with the cam keepers to secure the door tightly when rotated. |

| Locking Bar | It enables opening, closing, or locking the shipping containers. |

| Locking Bar Brackets | Known as bearing bracket is a device mounted to the locking bar at the top and bottom of a door locking bars and allow smooth rotation during operation |

| Locking Bar Guide | Its function is to keep the locking bar properly aligned and firmly supported against the door during operation. |

| Consolidated Data Plate | Displays essential container specifications such as CSC approval, weight limits, and container ID details |

| Door Retainer Hold Back | Keeps the door securely fixed in the open position by engaging with the door chain hook during loading or unloading operations. |

| Door Stopper / Slam Plate | Prevents the door from swinging |

Shipping Container Door Components / Container Door Parts

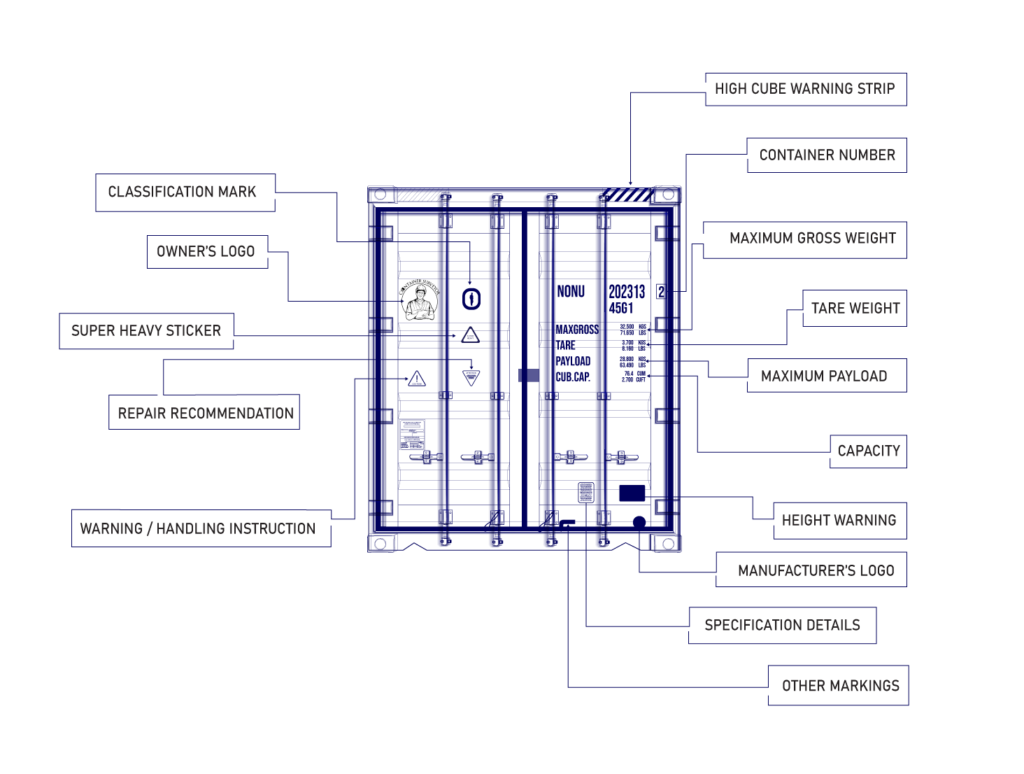

What are the markings and decals at the shipping container doors?

• Container Number including Check Digit

• Owners Logo

• ISO Code

• Maximum Gross Weight

• Tare Weight

• Net Weight

• Capacity

• Maximum Payload

• Manufacturer’s Logo

• Repair Recommendation

Read the article of “Shipping Container Markings | Decals | Labels | Stickers explained” to get more knowledge about markings and decals at the shipping container doors.

Common Types of Container Doors

Type 1 / (S1) Shipping Container Door

This type of door is commonly found on storage containers. It’s made from flat steel panels with a single locking bar, and because it’s lighter than regular shipping container doors, it opens and closes much more smoothly.

Type 2 / (S2) Doors

This type is commonly found on shipping containers and is made with thick corrugated steel, rubber gaskets, and sturdy door components. Type 2 doors are highly secure and watertight, making them ideal for heavy-duty storage, especially on construction sites.

Type 3 / (S3) Doors

Type 3 doors combine features of both the first and second types. They’re built with flat steel panels and have double locking arms, making them great for containers that require frequent access while still keeping stored items secure.

Shipping Container Doors – Inspection Criteria / Condition / Action

| Criteria | Condition | Action |

|---|---|---|

| COA Criteria for Cargo Worthy | Door Not operational & not light tight | Repair required |

| Holed, Cut, torn, broken, cracked | Straighten and weld or patch or insert, or replace | |

| Unified Container Inspection and Repair Criteria (UCIRC) | Holed, cut, torn, broken, cracked component or weld, or deformation affecting security and operation of doors | Straighten, weld or straighten and weld, or patch, or insert, or replace |

| Missing / broken or loose parts which affect door operation or weathertightness | Replace or refit | |

| The Institute of International Container Lessors (IICL) | ||

| Door Assembly, including hardware | Cut, torn, holed, cracked, broken, missing | Repair Required |

| Missing or loose fasteners | Repair Required | |

| Deformation of bend, bow, dent, seized, frozen, stiff | If door operation or securement is impaired – REPAIR | |

| Not light tight | Repair Required | |

| Door Panel | if internal cube intrusion is greater than 35mm | Repair Required |

Apart from the standard inspection criteria, corrosion can increase the chances of the container doors becoming holed over time. Corrosion is commonly found behind the Consolidated Data Plate, and also along the bottom and top stiffener edges due to continuous usage and exposure. Furthermore, a bent J-bar can impair proper door operation by restricting the locking bar movement. Stiff or seized hinges also negatively impact the door’s ability to open and close smoothly. (door operation) In some cases, fasteners may be missing from the door structure. When this happens, small light leaks can appear around the door.

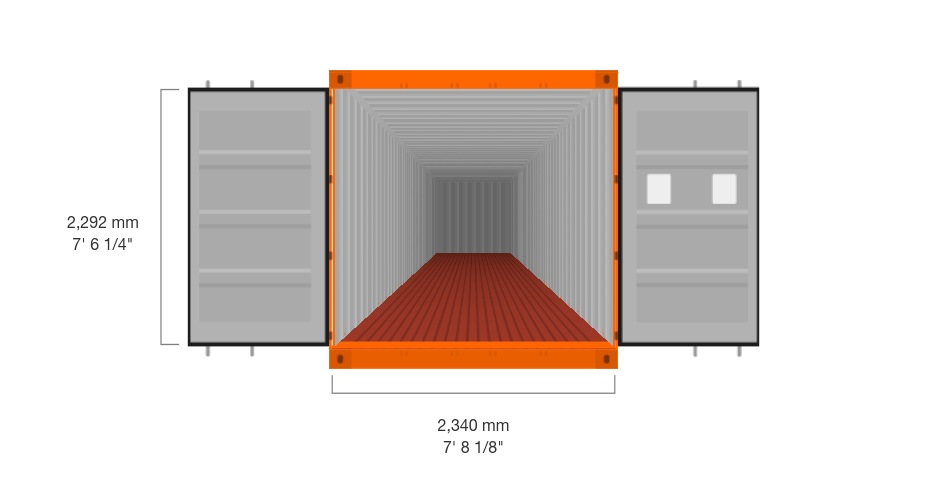

Shipping Container Door Opening Dimensions

Door openings are a key detail that’s often ignored but can lead to serious issues. In most standard containers, the door width is around 7 feet 8 inches, while the height is about 7 feet 5 inches. High cube containers come with slightly taller doors.