Table of Contents

Containerization of Shipping

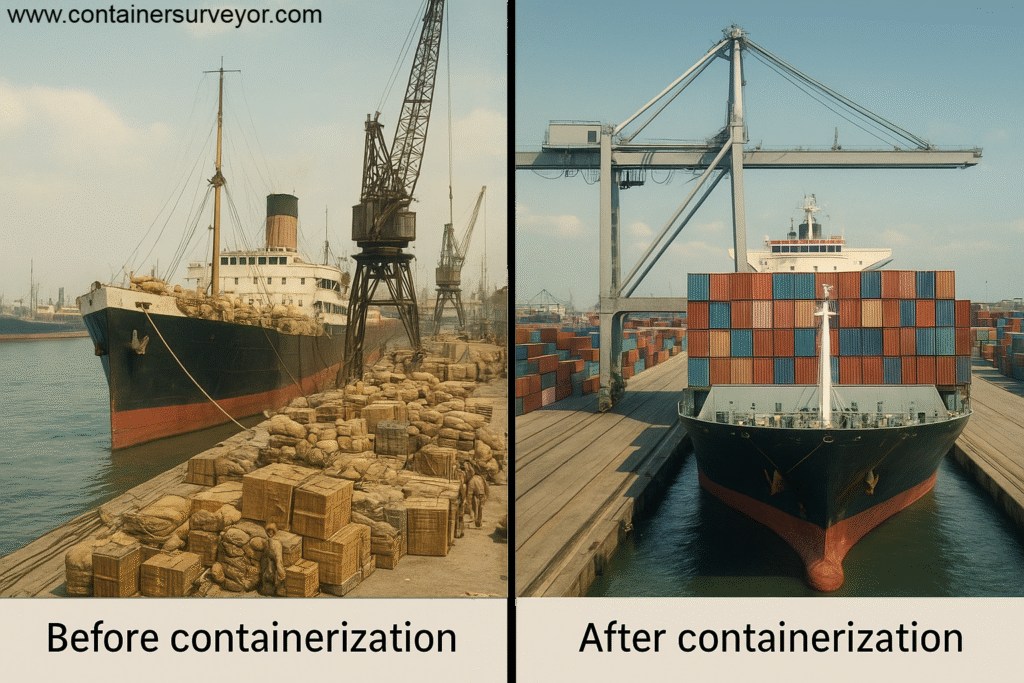

The history of shipping containers begins with containerization; A system where goods are packed into large, standardized steel boxes called shipping containers (or intermodal containers). These containers can be transferred easily between trucks, ships, and trains without ever unloading the cargo inside.

In the early days, workers had to load cargo piece by piece onto ships. This was slow, labor-intensive, and came with high risks such as damage and theft. But with the introduction of containerization, shipping became faster, safer, and far more efficient.

Containerization transformed global trade by making it possible to:

- Keep cargo inside one sealed container from origin to destination.

- Speed up loading and unloading operations.

- Reduce damage and theft because containers are locked and sealed.

- Move cargo easily across multiple transport modes of rail, sea, and road, without repacking.

Life Before Containers (Pre-1950s)

Before standard shipping containers existed, global trade looked completely different. The process was slow, labor-heavy, and full of risks.

01. Break-Bulk Cargo System

In the past, goods were shipped as individual items such as boxes, sacks, barrels, crates, and bundles. Each piece had to be handled separately, which made loading and unloading a slow and labor-intensive process. As a result, ships often spent more time in port than at sea.

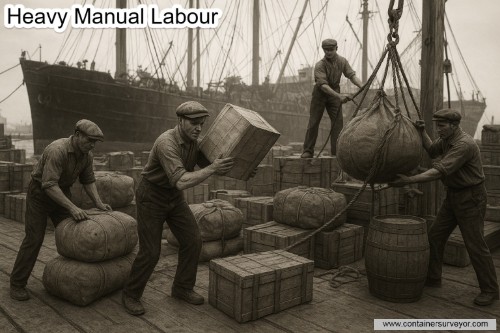

02. Heavy Manual Labour

Dockworkers (stevedores) had to carry or lift each item by hand & Cargo was stacked manually using ropes, hooks, and nets.

This made the process:

- Time consuming

- Physically dangerous

- Prone to accidents

03. High Cargo Theft & Damage

In those days, losses were common and considered a normal part of the business. Since many packages were small, they were often stolen, and fragile items frequently broke due to rough handling during loading and unloading.

04. Poor Space Utilization in Ships

In those days, loading plans were very complicated because of the irregular sizes and shapes of the cargo. Ships often sailed with unused space, which reduced overall efficiency.

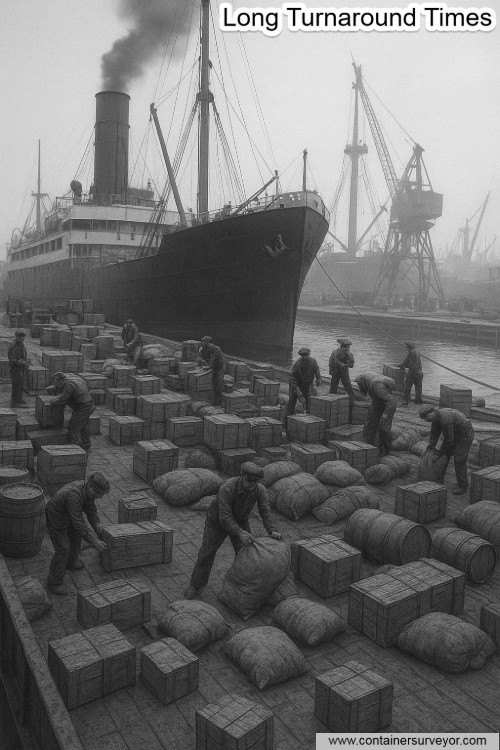

05. Long Turnaround Times

Ships often took days or even weeks to fully load or unload. This slowed down global trade and pushed shipping costs higher. Ports also became congested because operations were so slow and labor-intensive.

06. No Standardization

There was no universal size, packaging method, or handling process. Every port used different equipment and working methods, making international shipping inconsistent and highly inefficient.

07. High Cost of Shipping

High labour costs, long handling times, and frequent cargo losses all added up to expensive freight charges. As a result, only large companies could afford long-distance trade.

The Birth of Containerization (1950s–1960s)

The modern container revolution began when the shipping industry finally recognized that the traditional break-bulk system had reached its limits too slow to support growing trade, too costly due to heavy labour needs, and far too inefficient to meet global demand. This period gave rise to the idea of using standardized containers that could move seamlessly between ships, trucks, and trains. It marked the stage of invention, experimentation, and early adoption, setting the foundation for the global containerized supply chain we rely on today.

01. Malcolm McLean – The Visionary (1950s)

Malcolm McLean, an American trucking entrepreneur, noticed how ports wasted hours loading cargo piece by piece. Watching this inefficiency every day, he asked a simple but revolutionary question:

“Why not load the entire truck trailer onto the ship?”

This single idea became the foundation of modern containerization and changed global trade forever.

02. The First Container Ship – 1956

In 1956, McLean converted a WWII oil tanker, the Ideal X, into the world’s first container ship.

It carried 58 containers on its maiden voyage from Newark to Houston.

The results were dramatic:

- Loading time dropped sharply

- Theft and cargo damage were significantly reduced

- Transportation costs fell by nearly 90%

This single voyage proved that containers could revolutionize the shipping industry.

03. Standardization Begins (Late 1950s – 1960s)

For containers to work globally, the world needed a common system.

During the 1960s, ISO (International Organization for Standardization) established worldwide standards for:

- Container sizes (20 ft and 40 ft)

- Corner castings

- Lifting equipment

- Twist locks and locking systems

These standards allowed containers to be handled the same way in any port, on any truck, or on any train.

04. Rise of Intermodal Transport

With standardization in place, containers could move seamlessly between:

- Trucks

- Trains

- Ships

All without ever opening the container.

This marked the beginning of true intermodal logistics, cutting time, labour, and damage across the entire supply chain.

05. Rapid Expansion in the 1960s

As the benefits became undeniable, more shipping lines embraced containerization. Ports began to invest heavily in:

- Gantry cranes

- Container yards

- Stacking and storage systems

Governments and trade organizations also supported the shift, recognizing its ability to boost national and global trade.

06. Early Challenges

The early years weren’t easy. The industry faced:

- The high cost of converting ships and modernizing ports

- Resistance from labour unions

- Multiple competing container designs before standardization

- The need for global acceptance to make the system work

But despite these obstacles, the improvements in speed, safety, and cost were impossible to ignore.

The Container Era Begins

By the late 1960s, containerization was widely accepted as the future of global shipping.

It laid the groundwork for:

- Faster and more efficient port operations

- Dramatically lower shipping costs

- Explosive growth in global trade

- The modern supply chains that power the world today