Table of Contents

Shipping Container Types and Sizes: Complete Guide for Global Trade

Shipping containers are standardized large metal boxes used for transporting goods across the globe. Millions of different products need to be moved worldwide, each with different shapes, sizes, and requirements. To select the perfect shipping container or to decide which container is right for your cargo this article will help you navigate the world of shipping containers.

They are also considered the backbone of international logistics, as they enable the safe and efficient movement of goods across oceans, roads, and railways. With the variety of container types and sizes available, almost any kind of cargo can be transported ranging from machinery and vehicles to food, chemicals, and bulk commodities.

Why is it important to choose the correct shipping container types ?

- Protect cargo

- Ensure safety and compliance

- Optimize space and cost efficiency

- Prevent logistical delays and hassles

Which Shipping Container Types Are Commonly Used Worldwide?

- Dry Containers / Standard Containers

- High Cube Containers

- Refrigerated Containers (Reefers)

- Open Top Containers

- Flat Rack Containers

- Tank Containers (ISO Tanks)

1. Dry Containers / Standard Containers / General Purpose Containers

Dry Containers are the most common freight units used in sea transport. They are also known as standard containers, dry van containers, or general-purpose containers. The term “dry” is used because the container is fully enclosed, providing weatherproof protection for cargo.

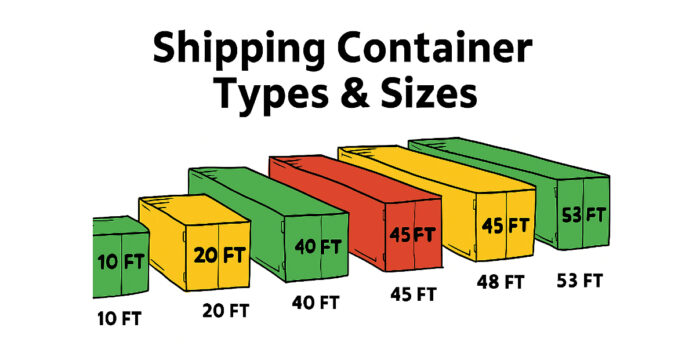

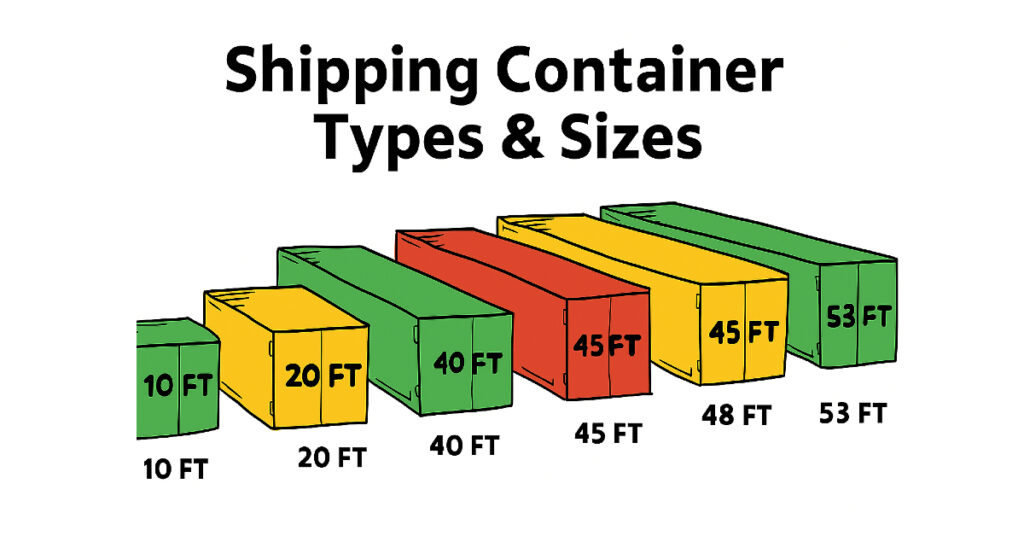

The most common sizes are 20-foot and 40-foot, though 45-foot containers are also available. These containers are designed for both sea and land transport. They do not have temperature controls and remain the most widely used container type in the world, with about 90% of sea freight transported in them. Dry containers also come in different dimensions and variants.

Examples of cargo: furniture, clothing, electronics, machinery, packaged food, and paper goods.

20ft Shipping Container

A 20-foot container is approximately 20 feet long, 8 feet wide, and 8.5 feet high. It is one of the most commonly used units in the global shipping industry and is often referred to as a standard 20-foot container or 20GP container.

In addition to the standard version, there is also a 20-foot High Cube container (20HC). The high cube has the same length and width as the standard 20GP, but its height is increased to 9 feet 6 inches. This extra height provides around 30% more internal capacity, offering about 1,520 cubic feet of space compared to the standard container’s 1,172 cubic feet. In simple terms, the high cube design gives nearly 350 cubic feet of additional volume, making it a preferred choice for shippers who need more space without increasing the container’s length.

20ft Shipping Container Types for Houses & Offices – A 20ft container is one of the most versatile shipping container types, widely used for compact houses and portable offices. It’s easy to transport, budget-friendly, and ideal for site offices, cabins, or small living spaces.

1 TEU = One 20ft container

1 FEU = One 40ft container (equal to 2 TEUs)

40ft Shipping Container

A 40-foot container measures about 40 feet in length, 8 feet in width, and 8.5 feet in height. It is one of the most widely used container types in global trade and is often called a standard 40-foot container or 40GP container. Because of its larger size, it can carry almost double the volume of a 20-foot container, making it ideal for bulkier shipments or when consolidating cargo.

There is also a 40-foot High Cube container (40HC). This type has the same length and width as the 40GP but comes with an extra foot of height, measuring 9 feet 6 inches tall. That additional height gives more storage capacity—around 2,694 cubic feet compared to the standard 40GP’s 2,390 cubic feet. In simple terms, the 40HC offers nearly 300 extra cubic feet of space, making it a practical choice for cargo that is light but takes up more room, such as bulky machinery, furniture, or lightweight manufactured goods.

40ft Shipping Container Types for Houses & Offices – Among the larger shipping container types, the 40ft container is preferred for spacious homes and long-term office setups. The High Cube version provides extra headroom, making it perfect for family houses, meeting rooms, or training centers.

Exploring Less Common Shipping Container Sizes

Not every shipment relies on the standard 20ft or 40ft containers. Some cargo requires different dimensions, and that’s where less common container sizes come in. These special sizes are designed to handle unique shipping needs, offering more flexibility for oversized, lightweight, or project-specific cargo.

10ft Shipping Container

10ft Shipping Container – Dimensions

A 10ft shipping container is one of the smallest standard container sizes available. Its compact structure makes it ideal for limited spaces where larger containers won’t fit.

External Dimensions: 2.9m (L) × 2.4m (W) × 2.5m (H)

Internal Dimensions: slightly smaller due to wall thickness

High Cube Option: 2.9m tall, offering extra headroom

10ft Shipping Container – Weight

A 10ft container weighs about 1,350kg. Built with strong corten steel, it is designed to handle harsh weather conditions and ensure the safety of stored items.

Common Uses of 10ft Containers

Storage – Ideal for tools, equipment, household items, or seasonal goods.

Small Offices or Site Cabins – Converted into compact offices for construction sites or events.

Retail & Food Outlets – Perfect for pop-up shops, coffee kiosks, or food stalls.

Transport – Handy for moving smaller loads that don’t require a 20ft container.

Workshops or Hobby Rooms – Can be customized for personal use.

Benefits of a 10ft Shipping Container

Space-Saving – Fits into tight spaces where larger containers are impractical.

Portable – Easier to move and position.

Cost-Effective – Lower rental or purchase cost compared to bigger sizes.

Versatile – Can be customized with doors, windows, insulation, or shelving.

45ft Shipping Container

5ft Shipping Container – Dimensions

A 45ft shipping container is one of the largest standard container types in the market. It offers maximum space for shippers and businesses that need to move or store large volumes of goods.

External Dimensions: 13.7m (L) × 2.4m (W) × 2.9m (H) (High Cube)

Internal Dimensions: slightly smaller due to wall thickness

Capacity: around 86m³, giving more room than a 40ft container. Most 45ft containers are built as High Cube versions, which provide additional height for oversized cargo.

5ft Shipping Container – Weight

A standard 45ft High Cube container weighs about 4,800kg (tare weight). Despite its large size, it is made of strong corten steel to handle heavy loads and long-distance shipping.

.

Common Uses of 45ft Containers

International Shipping – Large capacity for high-volume cargo.

Bulk Storage – Cost-effective solution for warehouses or distribution hubs.

Converted Spaces – Can be transformed into offices, homes, or classrooms.

Industrial Use – Great for oversized machinery or raw materials.

Retail & Events – Popular for large pop-up shops, exhibition stalls, or cafes

Benefits of a 45ft Shipping Container

Maximum Capacity – Provides more loading space than 20ft and 40ft units.

Efficient Transport – Reduces the need for multiple containers.

Durable & Secure – Built for international standards with strong steel walls.

Versatile Customization – Can be adapted for living, working, or storage needs.

48’ft Shipping Container

48ft Shipping Container – Dimensions

External Dimensions: 14.6m (L) × 2.4m (W) × 2.9m (H) (High Cube design is common)

Internal Dimensions: slightly less due to wall and door thickness

Capacity: around 86–88m³, depending on design

48ft Shipping Container – Weight

A 48ft container weighs around 4,800–5,000kg (tare weight). It’s made from strong steel and designed for heavy-duty use, ensuring durability during long-haul transport.

Common Uses of 48ft Containers

Domestic Transport in North America – Widely used on trucks and rail for inland cargo.

High-Volume Shipping – Suitable for goods that take up space but are not extremely heavy.

Bulk Storage – Excellent for storing large inventories or seasonal stock.

Converted Spaces – Can be used for container homes, offices, workshops, or commercial setups.

Events & Exhibitions – Offers plenty of room for pop-up displays and mobile business units.

Benefits of a 48ft Shipping Container

More Capacity – Extra 3ft compared to a 45ft container means more storage volume.

Efficient for Certain Markets – Fits U.S. domestic transport networks.

Durable & Weatherproof – Built from corten steel for long-lasting performance.

Customizable – Can be adapted with insulation, windows, doors, or shelving.

2. Reefer Container (Refrigerated Containers)

You may have noticed shipping containers in various colours, but one that often stands out is the white container. This type isn’t just about looks it’s called a Reefer Container.

Think of it as a moving refrigerator! Reefer containers (short for refrigerated containers) are also known as temperature-controlled containers. They play a crucial role in global logistics, as they are specially designed to transport temperature-sensitive cargo safely over long distances.

Reefer containers are commonly used to ship:

- Frozen and chilled food (such as fruits, vegetables, seafood, and meat)

- Pharmaceuticals and vaccines

- Chocolate and other temperature-sensitive goods

The most common sizes of reefer containers are 20ft, 40ft standard, and 40ft high cube (HC). However, some manufacturers also produce 10ft reefers, depending on the model and transport requirements.

Each reefer container can maintain a specific temperature range, typically from -30°C to +30°C, allowing operators to adjust the internal conditions according to the type of cargo being carried.

Many shipping lines now make use of idle reefer containers by offering them for dry cargo transport at the same or even lower rates than standard dry containers. These containers, known as Non Operating Reefer Container (NORs) or sometimes reefers-as-dry (RADs), are still regular reefer units the only difference is that their cooling systems are switched off. Once deactivated, they can carry non-temperature-sensitive goods just like a dry container, turning an unused asset into a practical and cost-effective solution.

3. Insulated Container

- Similar to reefers but with added insulation.

- Equipped with heating/cooling compressors.

- Used for temperature-sensitive products like blood, organs, and specialty chemicals.

4. Open Top Container

Open top containers can be easily identified as shipping containers without a fixed roof (roof panel) or ceiling panel. This type of container is specifically designed to carry specialized cargo, mainly from the construction, agriculture, and industrial sectors.

In simple terms, open top containers are used to transport oversized or oddly shaped cargo that cannot fit through the standard container doors. That’s the main reason they don’t have a roof panel it allows cargo to be loaded and unloaded from the top. Often, the cargo loaded into these containers exceeds the container’s height, which is why such shipments are commonly referred to as out of gauge (OOG) cargo.

Although these containers do not have a permanent roof, they come equipped with a removable PVC tarpaulin cover and roof bows. The roof bows act as supports to prevent the tarpaulin from sagging into the container. If shippers need to protect their cargo from weather or other external factors, the tarpaulin can be secured over the top.

Some models of open top containers also feature a swing header above the door, which allows for easier loading and unloading of heavy or tall cargo. This practical design makes open top containers an ideal solution for transporting machinery, construction materials, and other oversized items that can’t fit into a standard box-type container.

5. Flat Rack Container

- Collapsible sides or no sides/roof at all.

- Ideal for oversized machinery, vehicles, or construction materials.

- Provides easy access for loading heavy cargo.

6. Tank Container (ISO Tank)

- Made of anti-corrosive steel.

- Designed for liquids such as wine, chemicals, and oils.

- Must be filled between 80% and 95% for safety.

7. Bulk Container

- Specially designed for dry bulk goods.

- Commonly used for grains, coffee beans, animal feed, and spices.

- Can also carry general cargo when required.

8. Ventilated Container

- Built with ventilation to reduce moisture buildup.

- Used for goods like cocoa beans, coffee, and other organic cargo.

Choosing the Right Shipping Container Type

When selecting a container, consider:

- Cargo type – Dry, refrigerated, liquid, bulk, or oversized.

- Weight vs volume – 20ft is better for heavy cargo; 40ft for lighter, bulky cargo.

- Special requirements – Temperature control, ventilation, or extra space.

- Regional availability – Sizes like 48ft and 53ft are common in the U.S. but rare elsewhere.

Choosing the correct container saves costs, ensures safety, and prevents delays.