Table of Contents

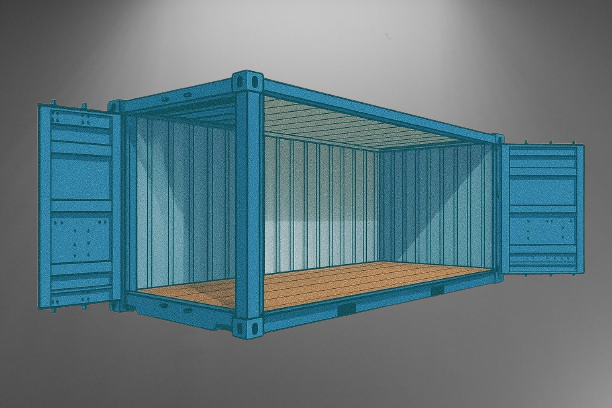

01. DRY CONTAINERS / GENERAL PURPOSE CONTAINERS

| Container Type | DRY CONTAINERS |

| Description | Dry containers are among the most widely used shipping container types in global trade. Designed for both sea and inland transport, dry containers account for nearly 90% of sea freight shipments, making them the most popular choice among all shipping container types. |

| Other Names | Standard containers / General Purpose Containers / GP Container / Dry Van Container |

| Typical Use / Cargo | Furniture, clothing, electronics, machinery, packaged foods, and paper-based products. |

| Size Range (FT) | 20-foot (GP/HC) 40-foot (GP/HC) 45-foot & 48-foot etc. |

| ISO Codes | 22G1 / 25G1 / 42G1 / 45G1 / LEG1 |

| Special Features | Dry Containers fully enclosed units that provide complete weatherproof protection for goods. |

| Advantages | Easy to find and use anywhere (sea, rail, road) & Keeps cargo safe from weather and damage. |

| Limitations | Can’t fit oversized & perishable or special cargo & No airflow or temperature control |

ISO Code Breakdown (Example – 42G1)

4 → Length – 40ft container

2 → Height – 8ft 6in (standard height)

G → General-purpose dry container

1 → Standard general-purpose design

02. REEFER CONTAINERS / REFRIGERATED CONTAINERS

| Container Type | REEFER CONTAINERS |

| Description | A reefer container is a specialized, temperature-controlled unit used to transport and store goods that need a consistent temperature. It’s ideal for temperature-sensitive cargo |

| Other Names | Refrigerated containers, Reefer unit, Temperature-controlled container, Reefer box |

| Typical Use / Cargo | Fresh Fruits & Vegetables, Frozen Foods, Dairy Products, Pharmaceuticals & Medical Goods, Vaccines, Insulin, Blood plasma, Medical samples, Beverages, Floral & Agricultural Products, Chemicals (Temperature-sensitive) |

| Size Range (FT) | 20GP Reefer (20ft Standard Reefer) 40GP Reefer (40ft Standard Reefer) 40HC Reefer (40ft High Cube Reefer) 45HC Reefer (45ft High Cube Reefer) |

| ISO Codes | 22R1 42R1 45R1 L5R1 |

| Special Features | Maintain a specific temperature range & Each container has its own refrigeration unit powered by electricity, allowing it to actively cool or heat as needed during transport |

| Advantages | Can carry cargo fresh and safe by maintaining temperature from origin to destination & also can carry a wide range of perishable goods |

| Limitations | High operating cost & The refrigeration control unit and insulation reduce internal cargo volume compared to standard dry containers |

ISO Code Breakdown (Example – 45R1)

4 → Length (40ft)

5 → Height (9ft 6in)

R → Reefer (refrigerated container)

1 → General purpose temperature-controlled type

03. FLAT RACK CONTAINERS

| Container Type | FLAT RACK CONTAINERS |

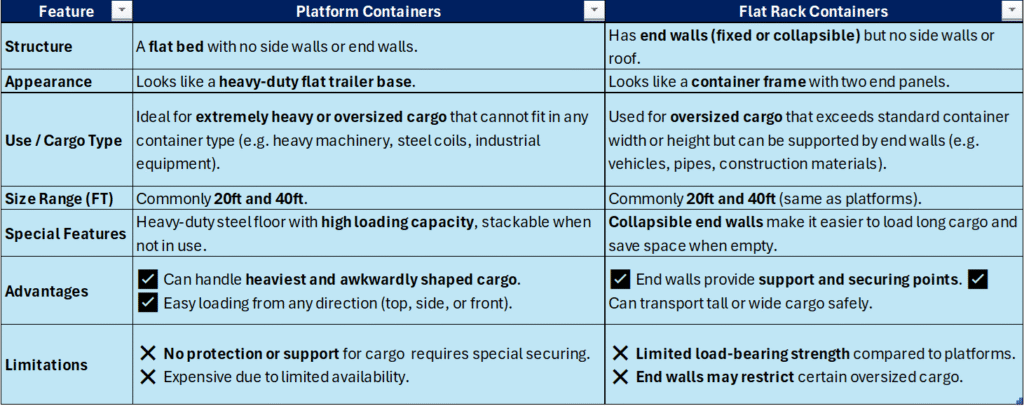

| Description | A special type of shipping container designed without a roof or side walls, having only fixed or foldable end walls. It is mainly used to carry large, heavy, or irregularly shaped cargo that cannot fit inside a regular container. |

| Other Names | Flatbed container, Collapsible flat rack, Non-collapsible flat rack, Platform container |

| Typical Use / Cargo | Mainly used to carry large, heavy, or irregularly shaped cargo such as Heavy Machinery, Vehicles & Equipment, Industrial Materials, Project Cargo / OOG (Out of Gauge), Boats & Yachts, Timber & Logs |

| Size Range (FT) | 20’ft Flat Rack, 40’ft Flat Rack, 40’ft High Cube Flat Rack (rare), 45’ft Flat Rack (limited use) |

| ISO Codes | 22P1, 22P3, 42P1, 42P3, 45P3 |

| Special Features | Collapsible End Walls & Fixed End Wall, Flexible Loading Options, Equipped with multiple lashing rings and twist-lock fittings to secure cargo |

| Advantages | Perfect for Oversized Cargo & Easy Loading & Unloading |

| Limitations | Limited Weather Protection & Higher Handling Cost |

ISO Code Breakdown Example – 42P3

4 → Length (40’ft)

2 → Height (8’ft 6in)

P → Platform / Flat Rack type

3 → Collapsible end walls

22P1 → 20ft Flat Rack with Fixed Ends

22P3 → 20ft Flat Rack with Collapsible Ends

04. PLATFORM CONTAINERS

| Container Type | PLATFORM CONTAINERS |

| Description | A platform container is a type of flat rack container that has no side or end walls. It is designed with a strong steel base and is mainly used for transporting heavy, oversized, or irregularly shaped cargo that cannot fit into standard containers. This container can also carry cargo that extends beyond its length or width. |

| Other Names | Flatbed container, Container platform, Flat platform, Base container, Flat container |

| Typical Use / Cargo | Heavy machinery and equipment, Construction materials, Oversized vehicles, Industrial tanks and generators, Large or irregularly shaped cargo that cannot fit in standard containers |

| Size Range (FT) | 20’ft Platform Container & 40ft Platform Container |

| ISO Codes | P22, P23, P24 & P42, P43, P44 |

| Special Features | Strong steel base and No side or end walls, allowing cargo to extend beyond the frame |

| Advantages | Ideal for Oversized Cargo & Flexible Loading Options |

| Limitations | Lack of Protection & Higher Transport and Handling Costs |

20ft Platform Container: (Example – P22)

P → Platform / Flat Rack type

2 → Length (20’ft)

2 → Height (8’ft 6 in)

End Walls: None

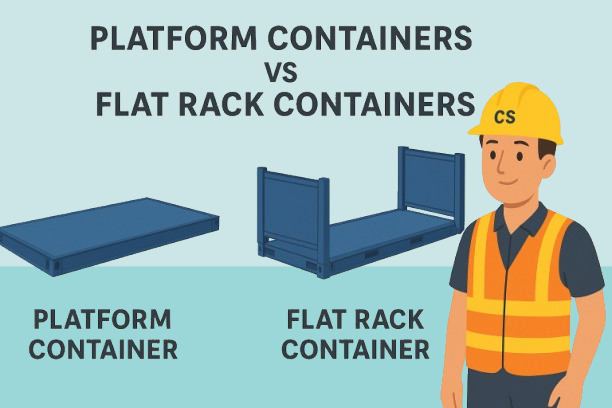

Platform Container vs Flat Rack Containers

Platform Container vs Flat Rack Containers

05. OPEN TOP CONTAINERS

| Container Type | OPEN TOP CONTAINERS |

| Description | Open top containers are shipping containers without a fixed roof panel. Compared to standard dry containers, open top containers are mainly used to transport oversized or out-of-gauge (OOG) cargo. |

| Other Names | OT Container, Open Roof Container, Removable Roof Container, Convertible Top Container, Top-Loading Container |

| Typical Use / Cargo | Oversized, irregularly shaped cargo, construction, industrial, and heavy machinery |

| Size Range (FT) | 20’ OT, 40’ OT, 20’OT High Cube (HC), and 40’OT High Cube (HC) sizes, 10’ft OT & 45’ft OT |

| ISO Codes | 22U1, 42U1 ,45U1 |

| Special Features | If the cargo cannot be loaded through the container doors, it can be loaded from the top using cranes or lifting equipment, and Swing header also useful for loading process, Tarpaulin of this open top container can be cover the cargo. |

| Advantages | Easy Loading of Oversized Cargo & Versatile for Various Industries |

| Limitations | Limited Weather Protection & Higher Handling Requirements |

ISO Code Breakdown Example – 42U1

4 → Length (40’ft)

2 → Height (8’ft 6 in)

U → Type (Open Top Container)

1 → Characteristics (Standard type with removable tarpaulin roof)

06. HARD TOP CONTAINER

| Container Type | HARD TOP CONTAINERS |

| Description | A Hard Top Container is a special type of shipping container designed with a removable, reinforced steel roof. Unlike open-top containers that use a tarpaulin cover, hard top containers offer better protection and durability because of their solid metal roof. The roof panels can be lifted off using a crane or forklift, making it ideal for oversized or bulky cargo that needs vertical handling. |

| Other Names | Steel Roof Containers, Removable Roof Containers, Top-Loading Containers, Heavy-Duty Roof Containers, Metal Roof Containers, Hard Roof Containers |

| Typical Use / Cargo | Heavy machinery and engines, marble, granite, and stone blocks, Industrial equipment and parts, Construction materials, Vehicles and spare parts |

| Size Range (FT) | 20’FT Hard Top, 40’FT Hard Top, 40’FT High Cube Hard Top |

| ISO Codes | |

| Special Features | it easier to load and unload cargo from the top, especially when goods are too tall or heavy to fit through the standard container doors, and hard top containers offer better protection and durability |

| Advantages | Easy Top Loading and Unloading & Superior Cargo Protection |

| Limitations | Heavier Structure and Reduced Payload & Higher Rental and Handling Costs |

07. ISO TANK CONTAINERS

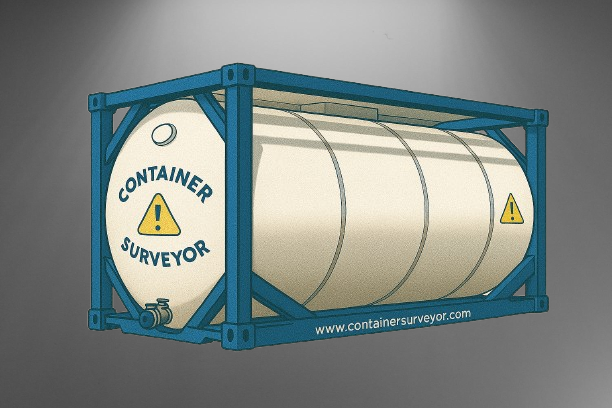

| Container Type | ISO TANK CONTAINERS |

| Description | A ISO Tank Containers is a multimodal ISO-framed pressure vessel that is used to transport liquids, gases, and powders. Cylindrical shaped tank containers are not just used for shipping, they can be used for storing the hazardous and non-hazardous materials |

| Other Names | Tank Containers, ISO Tanks, Intermodal Tank Containers Cylindrical Tank Containers, Tanktainers |

| Typical Use / Cargo | Chemicals and Industrial Liquids, Food-Grade Liquids, Fuels and Oils, Gases (Liquefied),Powder or Granular Cargo |

| Size Range (FT) | 20’FT ISO Tank, 30’FT ISO Tank, 40’FT ISO Tank |

| ISO Codes | 22T1, 22T4, 22T6, 30T8 |

| Special Features | Stainless Steel Construction, Strong Outer Frame, Insulation and Heating Options & Easy Cleaning and Maintenance |

| Advantages | Safe and Secure Transport & Cost-Effective for Bulk Liquids |

| Limitations | Limited to Liquid or Gas Cargo & Requires Specialized Cleaning and Handling |

Code Breakdown Example (22T6);

2 – Length (20 feet)

2 – Height (8’6”)

T – Tank container type

6 – Indicates features such as insulation or heating

08. OPEN SIDE CONTAINERS

| Container Type | OPEN SIDE CONTAINERS |

| Description | An Open Side Shipping Container is a standard ISO container with full-length doors along one side, in addition to the regular end doors. This side-opening design allows for easy access to the entire interior, making it simple to load and unload bulky, wide, or awkwardly shaped cargo. It’s also known as a Side Opening Container or Full Side Access Container, featuring bi-fold side doors that open completely for maximum convenience. These containers are popular for storage, exhibitions, and quick-loading operations where full side access is needed. |

| Other Names | Side Opening Containers, Full Side Access Containers, Side Door Containers, Open Side Access Containers, Dual Access Containers, Side Load Containers |

| Typical Use / Cargo | Palletized goods, Machinery or equipment, Event setups or pop-up shops, Construction materials, Storage units or workshops |

| Size Range (FT) | 20’FT Open Side Container, 40’FT Open Side Container, 40’FT High Cube Open Side Container |

| ISO Codes | 22U6, 42U6, 45U6 |

| Special Features | Easy Conversion Options & Full-Length Bi-Fold Side Doors |

| Advantages | Quick and Convenient Loading & Highly Versatile Usage |

| Limitations | Reduced Structural Strength & Higher Purchase and Maintenance Cost |

Code Breakdown Example (22U6);

2 → Length (20 feet)

2 → Height (8’6”)

U → Indicates a special container type (open side / open top / hard top)

6 → Specifies side-opening design

09. DOUBLE DOOR CONTAINERS

| Container Type | DOUBLE DOOR CONTAINERS |

| Description | A Double Door Container is a standard ISO container equipped with cargo doors on both ends, allowing easy access from either side. This dual-entry design makes loading and unloading faster and more efficient, especially for bulky or long cargo that needs handling from both ends. |

| Other Names | Tunnel Container, Tunnel-Type Container, Double-End Door Container, Two-Door Containers |

| Typical Use / Cargo | Palletized goods, Construction materials, Machinery and equipment, Consumer goods and general cargo, Vehicles or long items that need through-access |

| Size Range (FT) | 20ft Double Door Container, 40ft Double Door Container, 40ft High Cube Double Door Container |

| ISO Codes | 22G2, 42G2, 45G2 |

| Special Features | Dual Access Points, Faster Loading & Unloading, Flexible Cargo Access |

| Advantages | Easy and Fast Loading/Unloading & Flexible Cargo Handling |

| Limitations | Slightly Reduced Security & Higher Cost and Limited Availability |

ISO Code: 42G2

4 → Length: 40’ft

2 → Height: 8’ft 6 in

G → General purpose (dry type)

2 → Double door configuration

10. HALF HEIGHT CONTAINERS

| Container Type | HALF HEIGHT CONTAINERS |

| Description | Half height containers are compact shipping containers designed with a reduced height, typically half the height of a standard container. They are mainly used for carrying heavy, dense, or bulk cargo such as minerals, stones, scrap metal, and coal. Their low height makes loading and unloading easier, especially with cranes or forklifts, and helps maintain better stability during transport. |

| Other Names | Low cube containers, Half-size containers |

| Typical Use / Cargo | Transporting heavy bulk materials, Carrying scrap metal and construction debris, Storing and moving dense industrial goods where full-height containers are unnecessary |

| Size Range (FT) | 20’ft half height container & 40’ft half height container |

| ISO Codes | 22U6, 22U8, 42U6, 42U8 |

| Special Features | Built with a low-height design, making it easier and safer to handle heavy or dense cargo, Often comes with a removable or open-top roof, allowing quick loading and unloading using cranes or other lifting gear. |

| Advantages | Perfect for heavy materials like rocks, scrap, or minerals where height isn’t needed but strength is; The low height gives better stability during transport, reducing the risk of tipping or shifting. |

| Limitations | Offers less space, so it’s not suitable for tall or bulky cargo; Not as widely available as standard containers, which can make sourcing or renting one a bit harder. |

11. TUNNEL CONTAINERS

| Container Type | TUNNEL CONTAINERS |

| Description | Tunnel containers are the same as the double door containers that we discussed in number 9. |

| Other Names | Double Door Containers, Tunnel-Type Container, Double-End Door Container, Two-Door Containers |

| Typical Use / Cargo | Palletized cargo and packaged goods, Building and construction materials, Industrial machinery and equipment, General merchandise and consumer products & Vehicles |

| Size Range (FT) | 20ft Tunnel containers, 40ft Tunnel containers, 40ft High Cube Tunnel containers |

| ISO Codes | 22G2, 42G2, 45G2 |

| Special Features | Dual Access Points, Faster Loading & Unloading, Flexible Cargo Access |

| Advantages | Easy and Fast Loading/Unloading & Flexible Cargo Handling |

| Limitations | Slightly Reduced Security & Higher Cost and Limited Availability |

12. SPECIAL PURPOSE CONTAINERS

| Container Type | SPECIAL PURPOSE CONTAINERS |

| Description | A special purpose container is a customized shipping unit built to carry cargo that cannot be handled by standard containers. These containers are specially designed in unique shapes and sizes to suit specific goods, ensuring safe and efficient transport. The design and materials depend on the cargo type, with security and durability being top priorities. Though they are more expensive to build and transport, special purpose containers are essential for handling certain specialized shipments where standard containers are not suitable. |

| Other Names | Custom-built containers, Specialized containers, Non-standard containers, Purpose-built containers, Custom-designed containers, Modified containers |

| Typical Use / Cargo | They are often used for high-value, sensitive, or regulated cargo such as weapons, hazardous materials, or equipment requiring extra protection. |

| Size Range (FT) | The size range of special purpose containers can vary widely since they are custom built to suit specific cargo or operational needs. |

| ISO Codes | N/A |

| Special Features | Built with custom design and reinforced structure for specific cargo requirements, Can include enhanced security, insulation, or special fittings depending on cargo type. |

| Advantages | Ensures safe and secure transport of high-value goods. Customizable design to meet unique shipping needs. |

| Limitations | High production and transport cost compared to standard containers. Limited availability and may require special handling or equipment. |

13. INSULATED CONTAINERS

| Container Type | INSULATED CONTAINERS |

| Description | An insulated container is a shipping container built to keep the inside temperature steady and protect cargo from outside heat or cold. It does not have a cooling or heating unit like a reefer container but uses thick insulated walls, floors, and ceilings to reduce temperature changes |

| Other Names | Thermal container, Passive refrigerated container, Non-mechanical reefer, Temperature-controlled container |

| Typical Use / Cargo | Food items, beverages, and dairy products, Pharmaceuticals and chemicals, Perishable or temperature sensitive goods |

| Size Range (FT) | 20’ft Insulated Container, 40’ft Insulated Container |

| ISO Codes | 22H1, 45H1 |

| Special Features | Built with thick insulated walls, floors, and ceilings to reduce heat transfer. Maintains internal temperature without using mechanical cooling or heating units. |

| Advantages | Keeps cargo safe from temperature changes during transport. Energy-efficient and low maintenance compared to reefer containers. |

| Limitations | Cannot actively cool or heat the cargo Limited use for goods requiring strict temperature control |

Code Breakdown (Example – 22H1)

2 → Length: 20’ft

2 → Height: 8’ft 6 in

H → Insulated container

1 → General type

14. GARMENT CONTAINERS

| Container Type | GARMENT CONTAINERS |

| Description | A garment container is a specially arranged shipping container used for carrying clothing that needs to stay on hangers during transport. These containers are mainly used in the fashion and textile industry to move finished garments directly from factories to stores without folding or packing them in boxes. |

| Other Names | Garment-on-Hanger Container, GOH Container, Hanging Garment Container, Clothing Container, Apparel Container, Fashion Container, Textile Container, GOH Shipping Container, Garment Transport Container |

| Typical Use / Cargo | Finished garments such as shirts, suits, dresses, coats, and uniforms from factories to stores or distribution centers |

| Size Range (FT) | 20’foot dry container & 40’foot dry container |

| ISO Codes | same as dry container ISO codes |

| Special Features | Internal Hanging System & Convertible Interior |

| Advantages | Minimizes Handling and Damage & Saves Time and Labor Costs |

| Limitations | Limited Cargo Flexibility & Higher Setup and Maintenance Cost |

15. NON OPERATED REEFER CONTAINERS – NOR CONTAINERS

| Container Type | NOR CONTAINERS |

| Description | A Non-Operating Reefer (NOR) container is a refrigerated shipping container that is used to transport general cargo with its refrigeration unit turned off. In simple terms, it’s the same as a reefer container, but instead of carrying temperature-controlled goods |

| Other Names | Non Operated reefer containers, non operated reefer container, Reefer as Dry |

| Typical Use / Cargo | Electronics and household goods, Textiles, footwear, and apparel, Paper products, Agricultural products |

| Size Range (FT) | Same as 20’ft 40’ft and 40’HCRF |

| ISO Codes | Same ISO codes |

| Special Features | Transport general cargo with its refrigeration unit turned off |

| Advantages | Efficient Container Repositioning & Enhanced Cargo Protection |

| Limitations | Reduced Internal Space & Not Suitable for Heat-Sensitive or Bulky Cargo |

16. FLEXI BAG CONTAINERS

| Container Type | FLEXI BAG CONTAINERS |

| Description | A Flexi Bag Container is a standard dry container that has been modified to carry non-hazardous liquid cargo using a large flexible bladder or bag inside. This bag, made from multiple layers of polyethylene with an outer protective woven layer, converts the container into a bulk liquid transport unit without the need for traditional drums or ISO tank containers. |

| Other Names | Flexitank Container, Liquid Bag Container, Bulk Liquid Container, SeaBulk Container |

| Typical Use / Cargo | Edible oils (palm oil, sunflower oil, etc.), Wine, juice, and beverages, Liquid latex, Lubricants and base oils, Non-dangerous chemicals |

| Size Range (FT) | 20ft container (standard size used for flexibags) |

| ISO Codes | Flexi bags containers are not a separate ISO container type. |

| Special Features | Flexible liquid bladder system that fits securely inside a standard dry container. Disposable design :- no need for cleaning or return logistics after unloading. |

| Advantages | Flexible liquid bladder system that fits securely inside a standard dry container. Disposable design :- no need for cleaning or return logistics after unloading. |

| Limitations | Cost-effective & Efficient use of space Single-use only & Not suitable for hazardous or high-viscosity liquids |

17. SMART CONTAINER / GPS CONTAINER

| Container Type | SMART CONTAINERS |

| Description | A Smart Container is an upgraded shipping container equipped with integrated tracking and monitoring technology. These containers use built-in IoT (Internet of Things) sensors and GPS systems to collect real-time data about the container’s location, temperature, humidity, door activity, and even shock or tilt movements during transit. In simple terms, a Smart Container is a traditional shipping container with a digital brain designed to improve cargo visibility, safety, and supply chain efficiency. |

| Other Names | GPS Container, IoT-Enabled Container |

| Typical Use / Cargo | Smart containers are commonly used in sectors where real-time cargo visibility and control are critical, such as Pharmaceuticals and healthcare, Perishable goods, Electronics and high-value cargo, Automotive parts and industrial shipments |

| Size Range (FT) | 20ft and 40ft Dry Containers, Reefer Containers, Tank Containers |

| ISO Codes | ISO Codes depends on the using container |

| Special Features | Built-in GPS and sensor system for real-time location and condition tracking. Cloud-based data access, allowing shippers and consignees to monitor container status remotely. |

| Advantages | Enhanced cargo security & Supply chain visibility |

| Limitations | Higher operational cost & Dependence on network coverage |

18. SUPER RACK CONTAINER

| Container Type | SUPER RACK CONTAINER |

| Description | A Super Rack Container is a specialized type of flat rack container designed for extra-large and out-of-gauge (OOG) cargo. It features extendable posts and removable walls, offering greater flexibility in height and cargo handling compared to standard flat racks. |

| Other Names | Super Flat Rack container, Extended Flat Rack Container, High Post Flat Rack Container |

| Typical Use / Cargo | Oversized machinery and equipment, Wind turbine parts, Construction vehicles and components & Long or tall industrial materials |

| Size Range (FT) | 20 feet (20ft) 40 feet (40ft) |

| ISO Codes | |

| Special Features | Higher and adjustable corner posts for tall cargo & Foldable or removable end walls for flexibility |

| Advantages | Can carry oversized and over-height cargo that standard containers cannot accommodate & Strong and durable structure designed to handle very heavy loads safely. |

| Limitations | Offers no weather protection since sides and top are open & Requires special handling and securing, which increases loading time and cost. |