Table of Contents

Role of Container Lashing Fittings

Lashing Fittings Role: Shipping containers offer excellent opportunities for securing cargo through compact loading. Utilizing the corrugated steel structure of containers allows for a tight fit, especially when employing bracing techniques. This method ensures that individual items are snugly positioned, minimizing the risk of movement and potential damage during transportation.

An integral part of cargo securing within shipping containers is the use of lashing rings, also referred to as container lashing rings or tie-down rings. These rings serve as anchor points strategically positioned on the inner walls and floor of the container. Welded to the container’s base, these lashing rings provide secure attachment points for straps, chains, or other restraints, offering a reliable means to prevent cargo displacement during transit.

The inner lashing rings play a crucial role in the securement of cargo within shipping containers. These rings are welded to the container’s base, creating robust anchor points for attaching hooks to restrain and stabilize loads during transportation. This ensures a reliable and effective system for securing diverse types of cargo, contributing to the overall safety and integrity of the shipping process.

What is the purpose of Container Lashings ?

Lashing fittings play a vital role in the world of transportation, specially crafted to keep cargo safe and sound within shipping containers. Imagine them as the guardians of your goods, working tirelessly to make sure everything stays securely in place. Their main job? To stop your cargo from sliding or tumbling around during the journey, guaranteeing it stays steady and protected. With a smart approach to anchoring and securing the cargo, these fittings are like the unsung heroes, ensuring your shipments arrive intact and free from any potential harm caused by unexpected movements or instability while on the move.

What are the common types of Container Lashing Fittings ?

- Lashing Rings

- Lashing Bars / Lashing Rods

Where I can see Lashings in the Shipping Container ?

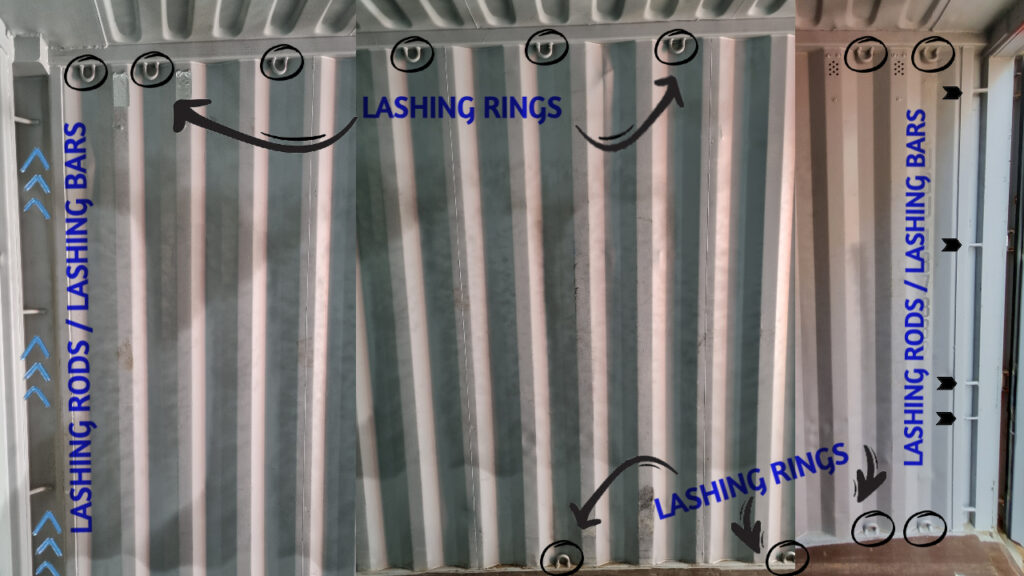

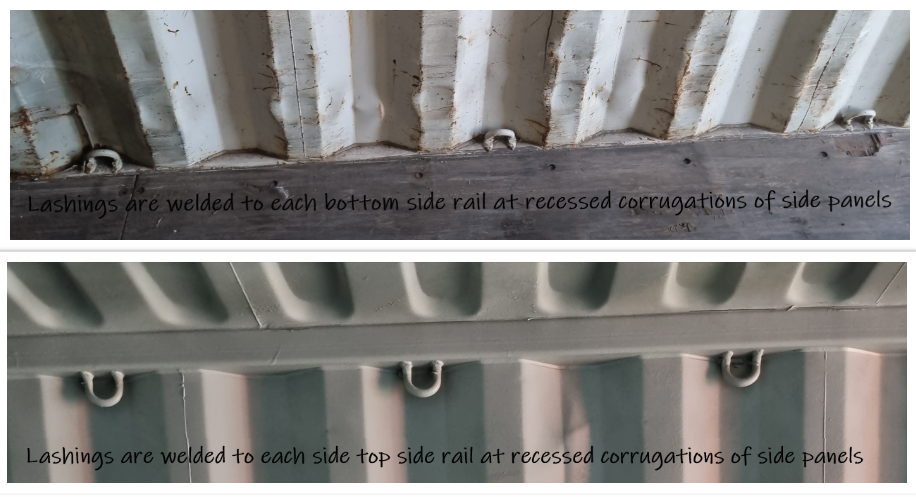

Lashing Rings are typically positioned on the interior side of standard dry van containers, welded to the top side rail of the container, the bottom side rail, and the interior recessed front and rear corner posts.

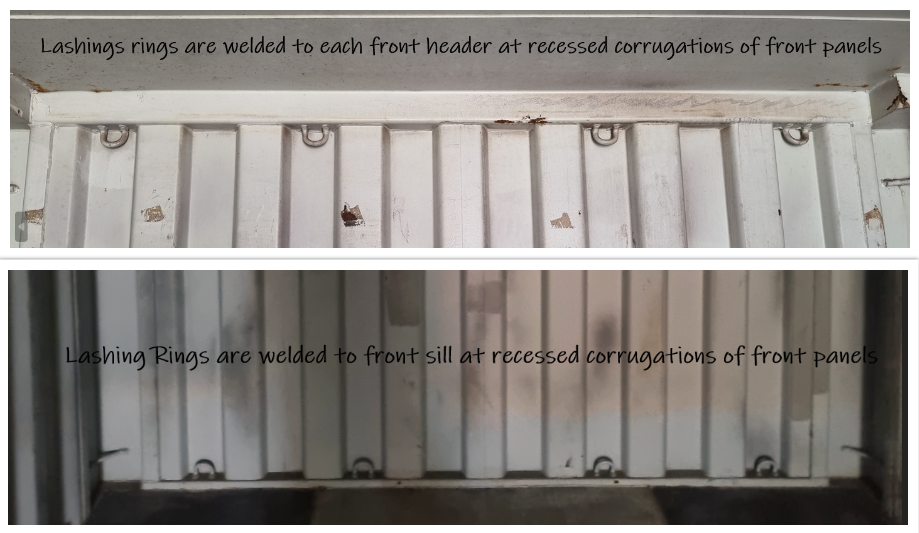

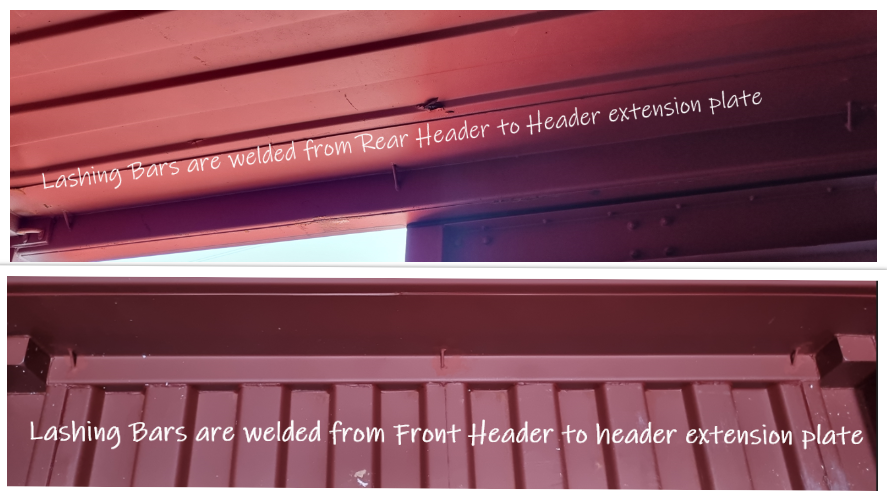

In certain containers, lashing rings can be observed welded on the front header at the recessed corrugations of the front panel. Additionally, some containers may feature lashing bars welded from the front header to the header extension plate, also welded to the front sill at the recessed corrugations of the front panel.

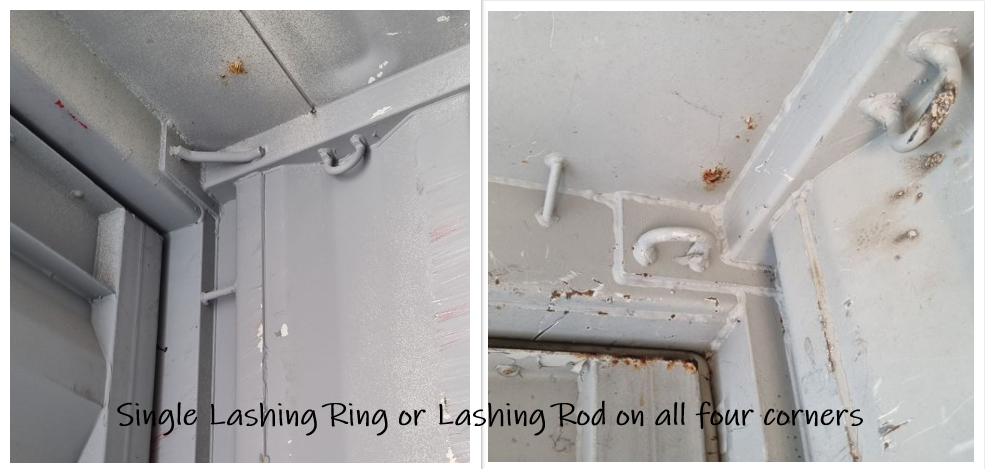

Furthermore, there are instances where containers have a lashing bar welded from the corner casting to the side top rail at all four corners. In some cases, lashing rings are also welded to the corner castings with the support of gusset plates at all four corners.

How many Lashings are available in a container ?

Lashings on 20’ft Container

In general 20’ft dry container contains minimum 20 lashings in total.

- 5 Lashings are welded to each side top side rail at recessed corrugations of side panels (Not extruded cargo space)

- 5 Lashings are welded to each bottom side rail at recessed corrugations of side panels (Not extruded cargo space)

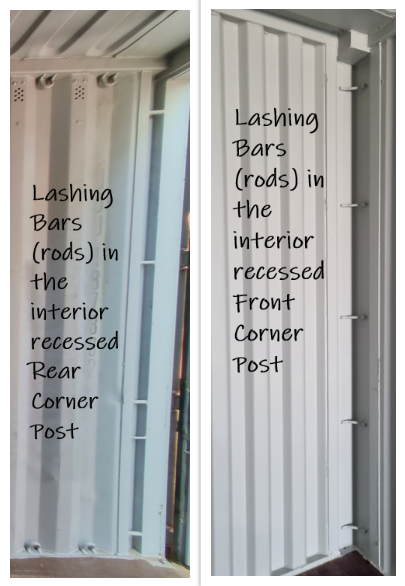

3 to 5 Lashing Bars (rods) contains interior recessed corner posts.

- 3 to 5 lashing bars (rods) in the interior recessed front corner post.

- 3 to 5 lashing bars (rods) in the interior recessed rear corner post.

3 to 5 Lashing Rings are welded to Front Header and Front Sill at recessed corrugations of front panels.

- 3 – 5 Lashings rings are welded to front header at recessed corrugations of front panels.

- 3 – 5 Lashing rings are welded to front sill at recessed corrugations of front panels.

Single Lashing Ring or Lashing Rod on all four corners.

2 to 5 lashing bars (rods) are welded from front and rear header to header extension plates.

- 2 – 5 lashing bars are welded from front header to header extension plate.

- 2 – 5 lashing bars are welded from rear header to header extension plate.

Lashings on 40’ft Container

In general 20’ft dry container contains minimum 20 lashings in total.

- 10 Lashings are welded to each side top side rail at recessed corrugations of side panels (Not extruded cargo space)

- 10 Lashings are welded to each bottom side rail at recessed corrugations of side panels (Not extruded cargo space)

3 – 5 Lashing Bars (rods) contains interior recessed corner posts.

- 3 to 5 lashing bars (rods) in the interior recessed front corner post.

- 3 to 5 lashing bars (rods) in the interior recessed rear corner post.

3 to 5 Lashing Rings are welded to Front Header and Front Sill at recessed corrugations of front panels.

- 3 – 5 Lashing rings are welded to front header at recessed corrugations of front panels.

- 3 – 5 Lashings rings are welded to front sill at recessed corrugations of front panels.

Single Lashing Ring or Lashing Rod on all four corners.

2 to 5 lashing bars (rods) are welded from front and rear header to header extension plates.

- 2 – 5 lashing bars are welded from front header to header extension plate.

- 2 – 5 lashing bars are welded from rear header to header extension plate.

Note: This information may vary based on the container line, manufacturing year, damages (whether missing or removed), and modifications (to meet special requirements)

What is a function of Lashing Fittings ?

Lashing rings and rods serve the purpose of facilitating proper cargo lashing inside the container.

Strength and Durability of Lashing Fittings ?

Lashing rings usually have a pulling capacity of 2 tons each.

What are the damages can be happen for Lashing Fittings ?

- Missing

- Bent

- Broken

- Loose

- Cut / Crack

- Lashing ring / rod not functional

- Improper materials

How to repair Lashing Rings | Lashing Rods | Lashing Bars ?

- Straightening

- Straightening & Welding

- Welding

- Replacement

Note : – Areas challenging to access and paint, such as lashing hooks, require special attention.

Fix any lashing bars or other fittings found in the corner post being replaced. Weld these bars or fittings in the exact positions they occupied in the previous corner post

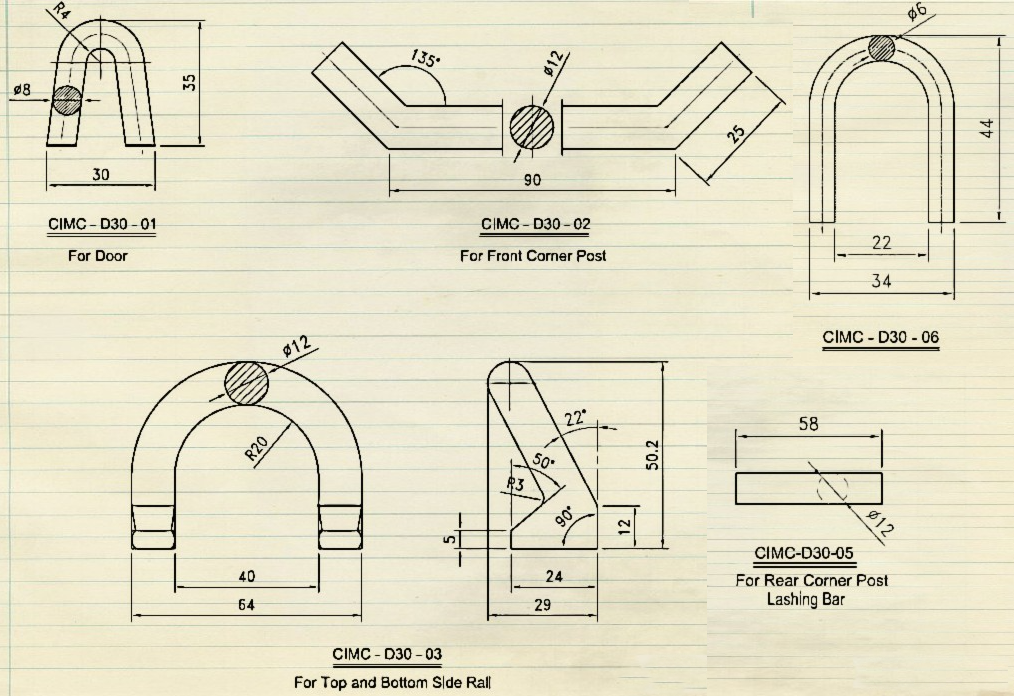

Dimension of Lashing Rings

Special Requirements of Lashing Fittings

In some cases, different customers have varying lashing requirements to secure their cargo. The video below serves as an example of how they prepare the interior structure using lashing to load powder into the container.

The example below illustrates the importance of lashing in securing vehicles inside the container.

How to stuff cargo inside a container

Disclaimer: The views expressed by the authors in this article do not necessarily reflect the views of CONTAINER SURVEYOR. Data and charts, if utilized, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and CONTAINER SURVEYOR do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.