As we all know, an average person can comfortably carry only about 15–25 kg over a short distance. But a standard 20ft container carries around 21,800 kg, and a 40ft High Cube container carries approximately 26,680 kg as payload. When you compare these numbers, it becomes clear how much weight a container actually holds and it’s practically impossible for humans to handle such massive loads using physical strength alone.

This is exactly where Container Handling Equipment comes into the picture. In different locations, we find different types of Container Handling Equipment, each built for specific purposes, different lifting capacities, and varying operating speeds.

In this article, we explore all of them. We will be discussing:

- Ship-to-Shore Container Handling Equipment

- Yard stacking and handling equipment

- Horizontal transport equipment used within terminals

- Container lifting equipment in container depots under both laden and empty conditions

- And finally, equipment used at customer premises such as warehouses, where containers are loaded & unloaded

By understanding the purpose and capability of each type of Container Handling Equipment, you’ll get a clearer picture of how the global container flow is managed safely, efficiently, and continuously.

Table of Contents

01. Ship to Shore Container Handling Equipment

1.1 STS Crane (Ship to Shore Gantry Crane)

An STS crane (Ship-to-Shore crane) is one of the biggest and most impressive machines you’ll spot at a container terminal. Its job is simple to understand but massive in importance it lifts containers between the ship and the shore, acting as the first point of contact when a vessel arrives. These cranes sit right along the quay edge, and their huge gantry structure allows them to smoothly load and unload containers between the vessel and the terminal with speed, accuracy, and a lot of power.

Common Industry Names for STS Cranes

- Quay Crane (QC)

- Container Quay Crane

- Ship-to-Shore Crane (STS Crane)

- Gantry Crane (Port Gantry Crane)

- Container Gantry Crane

- Dockside Gantry Crane

- Waterfront Gantry Crane

Brand/Design-Related Names

- Portainer Crane (brand name originally by Paceco)

- Super-Post-Panamax Crane (size/class)

- Post-Panamax Crane (size/class)

- Megamax Crane (extra-large STS)

1.2 Mobile Harbour Crane

A Mobile Harbour Crane (MHC) is one of the most flexible and hardworking machines you’ll find in a port. Unlike fixed cranes, an MHC can move around on wheels or rails, making it easy to position wherever it’s needed along the quay. Its biggest advantage is versatility the same crane can handle containers, bulk cargo, break-bulk, and even heavy lifts, making it a true all-rounder in cargo operations.

With its long outreach and fast operating speeds, an MHC can work efficiently with almost any vessel size, from small barges to large container ships. This flexibility helps ports achieve faster ship turnarounds and smoother operations.

Modern MHCs also come with advanced control systems, giving operators better precision, stability, and productivity. In simple terms, it’s a powerful, mobile, and multi-purpose crane that helps ports handle different types of cargo quickly and efficiently all with one machine.

Common Industry Names for Mobile Harbour Cranes

- Mobile Port Crane

- Harbour Mobile Crane

- Multipurpose Mobile Crane

- Quayside Mobile Crane

Brand/Design-Related Names

- Gottwald Mobile Harbour Crane

- Liebherr Mobile Harbour Crane

- Terex MHC

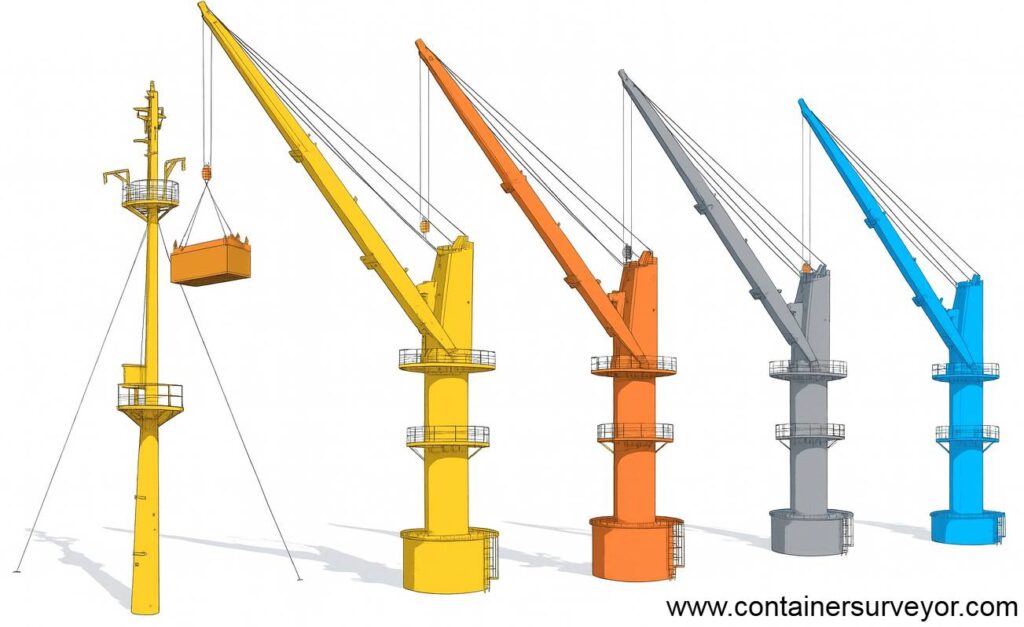

1.3 Ship’s Gear (Shipboard Cranes)

Ship’s Gear refers to the cargo-handling equipment that is built directly onto a vessel. Instead of depending on port cranes, these ships carry their own lifting systems usually cranes or derricks so they can load and unload cargo anywhere, even at ports with limited facilities.

You’ll mostly find Ship’s Gear on multipurpose vessels, break-bulk ships, heavy-lift vessels, and some geared container ships. These onboard cranes give the ship a big advantage: they can operate independently, making them perfect for remote ports, smaller terminals, or locations where shore-based equipment isn’t available.

In simple terms, Ship’s Gear makes a vessel self-sufficient, allowing it to handle its own cargo efficiently, no matter where it goes.

Common Industry Names for Ship’s Gear

- Ship’s Crane

- Vessel Crane

- Deck Crane

- Cargo Crane

- Geared Vessel Crane

Type-Specific Terms for Ship’s Gear

- Derrick Crane

- Cargo Derrick

- Twin-Lift Derrick

- Heavy-Lift Crane

02 Yard Stacking Equipment

2.1 Rubber Tyred Gantry Crane (RTG)

A Rubber-Tyred Gantry crane (RTG) is one of the busiest machines you’ll see in a container yard. It’s a tall, mobile gantry crane that moves on large rubber tires instead of fixed rails, giving it the freedom to travel across different yard blocks. Its main job is to lift, stack, and organize heavy intermodal containers efficiently, often stacking them several units high and several rows deep.

One of the biggest strengths of an RTG is its flexibility. Because it isn’t tied to a rail system, it can easily shift between blocks, span truck lanes, and support smoother traffic flow inside the terminal. This mobility helps ports handle more containers in less space.

Modern RTGs are often called “smart cranes” because they come equipped with advanced technologies such as Optical Character Recognition (OCR), position-tracking systems, and anti-sway controls. These features help operators identify containers quickly, place them accurately, and speed up truck turnaround times.

In simple terms, an RTG is the workhorse of the yard, keeping containers neatly stacked and operations running smoothly in busy storage areas.

Different ports use various terms referring to the same equipment

- RTG Crane

- Yard Gantry Crane

- Mobile Yard Crane

- Rubber-Tired Yard Gantry

- Container Stacking Crane

2.2 Rail Mounted Gantry Crane (RMG)

A Rail-Mounted Gantry crane (RMG) is a powerful, rail-guided yard crane designed for heavy, high-precision container handling. You’ll usually find RMGs in container terminals, intermodal yards, and rail yards, where they play a major role in lifting, stacking, and moving containers efficiently over large areas.

Because they operate on fixed rails, RMGs offer exceptional stability, accuracy, and lifting capacity, making them ideal for high-density stacking where space is limited. Their wide span and tall structure allow them to cover multiple container rows and reach impressive stacking heights.

Modern RMGs often come equipped with advanced automation, anti-sway systems, remote operation, and position-tracking technology. These features help speed up operations, reduce human error, and increase overall throughput which is why RMGs are considered essential equipment in today’s busy logistics hubs.

Similar / Alternative Names

- RMG Crane

- Rail-Mounted Yard Crane

- Yard Gantry Crane (RMG Type)

- Intermodal Gantry Crane

- Container Stacking Gantry

2.3 Reach Stacker

A Reach Stacker is a powerful, multi-purpose vehicle commonly seen in ports, rail yards, and large logistics hubs. It’s designed to lift, move, and stack shipping containers with ease, thanks to its long telescopic boom that can extend forward and upward. This boom is what makes a reach stacker unique it can reach over or behind other containers, allowing operators to stack rows deeper and higher without needing extra space.

Reach stackers are known for their speed, maneuverability, and flexibility. They can quickly pick up a container, travel across the yard, and place it exactly where it’s needed, making them perfect for operations that require constant movement. Their ability to handle both loaded and empty containers makes them one of the most relied-on machines in busy storage areas.

Many modern reach stackers also come with features like stability control, load-sensing hydraulics, and advanced operator cabins, which improve safety and precision during heavy lifting.

03 Horizontal Transport Equipment

3.1 Terminal Tractor

A terminal tractor also known as a yard truck, yard dog, or hostler is a specialized vehicle designed to move semi-trailers over short distances inside busy logistics areas. You’ll commonly see them in ports, container yards, warehouses, distribution centers, and rail terminals, where trailers need to be shifted constantly from one spot to another.

Unlike standard road trucks, terminal tractors are built for speed, maneuverability, and quick trailer handling. They have a compact design, a tight turning radius, and a powerful engine that makes it easy to move heavy trailers around crowded yards. One of their key features is the hydraulic fifth wheel, which allows the operator to lift and connect to a trailer in seconds no manual landing gear cranking required.

Because they are designed for frequent starts, stops, and tight movements, terminal tractors help yards operate far more efficiently than if they relied on large highway trucks for the same tasks.

3.2 Terminal Trailer / Bomb Cart

A Terminal Trailer, often called a Bomb Cart, is a strong, low-deck chassis used in ports and container terminals to move shipping containers quickly between the quay cranes and the yard. It’s built to carry all common container sizes 20ft, 40ft, and 45ft and is usually paired with a terminal tractor (dolly truck) that pulls it around the terminal.

What makes a terminal trailer so effective is its simple but heavy-duty design. It has a rugged frame, wide wheels, and quick-lock systems that securely hold containers in place during fast-paced movements. Because the structure is built for constant loading and unloading, it can handle repeated heavy cycles without slowing down operations.

These trailers are essential in modern ports because they allow containers to move smoothly and continuously from ship to yard, helping terminals achieve high throughput and reduce waiting times for cranes and trucks.

3.3 Straddle Carrier

A straddle carrier is a tall, gantry-style vehicle used in ports and container terminals to lift, move, and stack shipping containers. It’s called a “straddle” carrier because it literally stands over the container, picks it up with a spreader, and carries it underneath its frame — almost like the machine is giving the container a lift from the inside.

Straddle carriers are known for their speed, flexibility, and ability to move easily through busy yards. They can pick up containers from trucks, transport them across the terminal, and stack them two or three units high, depending on the model. Because they can lift and transport containers on their own, they reduce the need for extra equipment and help keep container flows smooth.

These machines are especially useful in terminals with high traffic because they can work independently, maneuver through tight spaces, and handle containers efficiently without relying on rail tracks or large cranes.

3.4 An Automated Guided Vehicle (AGV)

An Automated Guided Vehicle (AGV) is a driverless, mobile machine designed to move materials around a facility on its own. You’ll often see AGVs in warehouses, factories, distribution centers, and modern logistics hubs, where they help transport goods from one point to another without needing a human driver.

AGVs follow pre-planned routes or navigate using sensors such as lasers, cameras, magnets, or embedded floor wires. These systems allow them to travel safely, avoid obstacles, and stop immediately if something comes in their way.

The main benefit of AGVs is that they reduce manual labor, improve efficiency, and maintain consistent movement of materials throughout the facility. They are especially useful in operations that require repetitive tasks, like moving pallets, components, or finished goods.

04 Container Lifting Equipment (Container Yard/ Depot)

4.1 Empty Container Handler (ECH)

An empty container handler is a strong, high-reaching machine used in ports, depots, and container yards to lift, move, and stack empty shipping containers. Think of it as a heavy-duty forklift designed specifically for empties. Because empty containers are lighter, this machine can stack them very high, helping terminals save valuable yard space.

Instead of regular forks, it uses a spreader with twist-locks that grips the container securely from the top or sometimes from the side. This makes lifting safer and much faster, especially when handling multiple containers in a busy yard.

Empty handlers are known for their quick cycle times, tight turning radius, and excellent maneuverability, which allow operators to shift containers around efficiently whether arranging stacks, preparing units for inspection, or moving them for loading onto trucks

4.2 Heavy Forklifts (for laden containers)

A heavy forklift also called a heavy-duty forklift is a powerful industrial truck built to handle loads far beyond what a normal forklift can lift. These machines can carry anything from 10 tons to well over 50 tons, making them essential in environments where extremely heavy or oversized materials need to be moved.

They look like an oversized version of a standard forklift but with stronger frames, bigger forks, and high-capacity engines (usually diesel, though electric models exist too). Because of their strength and durability, heavy forklifts are commonly used outdoors in ports, container yards, construction sites, steel mills, timber yards, and large manufacturing facilities.

Their job is to safely lift and transport large items such as containers, steel coils, long timber pieces, machinery, concrete blocks, and other bulky materials that regular forklifts simply can’t handle.

4.3 Empty Forklift

The term “empty forklift” is most commonly used to describe a specialized machine called an Empty Container Handler. This heavy-duty equipment is designed specifically to lift, stack, and move empty shipping containers in ports, depots, and container yards. Unlike a regular forklift that handles pallets, this machine is built for height and reach.

Empty container handlers come with extendable arms and a top-mounted spreader with twist-locks, allowing them to safely grip empty containers and stack them several units high. This helps yards save space and organize empty units efficiently.

In some cases, people may use “empty forklift” to simply describe a standard forklift that isn’t carrying a load. When a forklift is empty, its balance and stability change, which operators must keep in mind during movement and turning.

05. Truck / Customer Premises Equipment

5.1 Side Loader / Side Lifter Truck

A Side Loader is a special truck or trailer fitted with hydraulic lifting cranes that can load, transport, and unload shipping containers all by itself. Instead of needing forklifts or yard cranes, the side loader simply lifts the container from the side, places it on the trailer, moves it to the destination, and unloads it again.

These machines are extremely useful in tight spaces, customer premises, remote locations, and places without container-handling equipment. They can also transfer containers between trailers, load onto rail wagons, stack containers, or place them safely on the ground for packing or unpacking. This makes side loaders one of the most flexible tools in container logistics.

5.2 Tilt / Tipper Chassis

A Container Tipper Frame (also called a Tilt or Tipper Chassis) is a trailer frame equipped with a hydraulic tipping system that can tilt a standard shipping container, usually 20ft or 40ft, to unload bulk materials such as grain, fertilizer, minerals, plastics, or waste.

Instead of using expensive bulk trailers or blower systems, a tipper chassis allows the container itself to act as the bulk carrier. This saves time, reduces costs, and makes unloading much safer and quicker.

Many of these frames can also work as regular container chassis, so the same trailer can transport goods like normal and then tip the container when it reaches the discharge site — offering excellent versatility.

5.3 Mobile Crane

Mobile cranes are versatile lifting machines used across ports, terminals, and logistics yards. Mounted on rubber tyres, they have a telescopic boom and operator cabin that can travel directly to the worksite.

In the container industry, mobile cranes help with tasks such as lifting containers on and off trucks, rail wagons, small vessels, barges, and handling oversized or awkward cargo that standard container cranes cannot manage.

Their ability to move freely around the yard makes them ideal for special lifts, emergency situations, construction work inside terminals, and moving cargo where fixed cranes are not available.

5.4 Container Loading Ramp

A container loading ramp is a strong, portable or fixed steel ramp that creates a safe bridge between the ground and the inside of a shipping container. This gentle incline allows forklifts, pallet jacks, and other loading equipment to drive smoothly in and out of the container.

By providing a stable, slip-resistant pathway, loading ramps help speed up loading/unloading, reduce manual handling, and improve safety for workers. They are commonly used in warehouses, factories, and logistics yards where containers need to be packed or unpacked quickly and safely.