Table of Contents

1.What is a Non Operating Reefer Container?

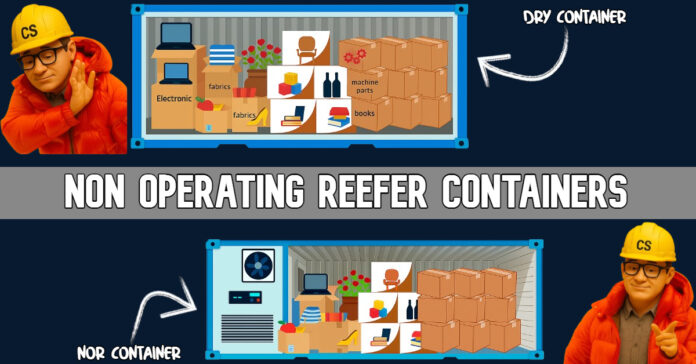

If you’ve ever come across the term NOR container, you might wonder what it really means. In simple terms, NOR stands for Non-Operating Reefer. It’s actually a refrigerated container (reefer) that’s being used just like a dry container but with its cooling unit switched off. In other words, a NOR container is a reefer container used for general cargo instead of temperature-controlled goods. The refrigeration system remains inactive during the shipment, allowing the container to function as a normal dry unit.

Cargo transported in these containers is often referred to as NOR cargo or non-operating reefer cargo. In shipping, this concept is also known as RAD, which stands for “Reefer as Dry”.

2. What does NOR stand for?

NOR containers stand for Non Operating Reefer containers. These are essentially refrigerated containers (reefers) that are used as dry containers when the refrigeration unit is turned off. Shipping lines and operators often use NOR containers to balance equipment movement.

3. The Use of NOR Containers

Depending on the country, export and import capacities vary, as do cargo requirements. Some countries import a high volume of temperature-controlled cargo, but their exports of such cargo are comparatively low. In these situations, shipping lines must return the reefer containers to specific destinations by repositioning them empty on the return voyage. To address this issue, shipping lines use these reefers as NOR containers, offering them at discounted rates as dry containers. This serves as a strategic solution to repositioning challenges benefiting shippers with lower costs while allowing shipping lines to reduce empty repositioning expenses through the use of NOR containers.

4. What is a Non Operating Reefer Container Specification?

| 20ft NOR Reefer | 40’ft NOR Reefer | 40’HC NOR reefer | |

|---|---|---|---|

| External Dimensions | |||

| Length | 20′ | 40′ | 40′ |

| Width | 8′ | 8′ | 8′ |

| Height | 8′ 6″ | 8′ 6″ | 9′ 6″ |

| Internal Dimensions | |||

| Length | 17′ 11″ | 37′ 11″ | 37′ |

| Width | 7′ 8″ | 7′ 8″ | 7′ 6″ |

| Height | 7′ 6″ | 7′ 6″ | 8′ 4″ |

| Door Opening | |||

| Width | 7′ 5″ | 7′ 6″ | 7′ 6″ |

| Height | 7′ 3″ | 7′ 6″ | 8′ 4″ |

| Internal Floor Space | 134 sqft | 284 sqft | 284 sqft |

| Volume | 1007 cu ft | 2132 cu ft | 2368 cu ft |

| Empty Tare Weight | 6530lbs | 9750lbs | 9950lbs |

5. How are reefers converted to non operating reefer containers?

Turning a reefer into a non-operating reefer container is a straightforward process, but it must be done carefully to ensure the container is ready for dry cargo use. Here’s how it’s typically done,

- Unload the Refrigerated Cargo

After the temperature-controlled shipment reaches its destination, all cargo is discharged from the reefer container. - Switch Off the Refrigeration Unit

The next step is to shut down and deactivate the cooling machinery, ensuring the unit is no longer operating as a temperature-controlled container. - Clean and Dry the Interior

The inside of the reefer is thoroughly cleaned and dried to remove any moisture, odor, or residue from the previous shipment. This makes the container suitable for loading dry cargo safely. - Prepare for the Next Voyage

Once the container is clean and dry, it’s ready to carry approved dry goods. These NOR containers are often offered at a lower freight rate compared to standard dry boxes, making them a cost-effective option for shippers.

6. What commodities can be shipped with NOR Containers?

Since reefer containers are primarily designed for temperature-controlled cargo, container operators do not allow just any type of cargo to be loaded into their reefer equipment. This is because reefers are expensive assets, and their repair and maintenance costs are significantly higher compared to dry containers.

Common types of cargo accepted for Non-Operating Reefer (NOR) use include:

- New electronic components

- Footwear

- Fabrics and clothing

- Furniture

- Handicrafts

- Toys

- Paper, books, and printed materials

- Canned beverages

- Preserved or packaged food items

Later in this article, we will also discuss the “Guidelines for the Carriage of Cargoes in Non-Operating Reefer Containers” issued by the Container Owners Association (COA) in conjunction with the Cargo Incident Notification System (CINS).

7. What are the inappropriate commodities to ship in NOR containers?

Not all cargo types are suitable for Non-Operating Reefer (NOR) containers. Although these units provide a cost-effective option for repositioning refrigerated containers, certain commodities can compromise the container’s structure, insulation, or internal surfaces. Below are examples of prohibited or unsuitable cargoes for NOR shipments.

- Dangerous goods: These materials can react with the container’s internal lining and pose a safety hazard during transit.

- Tyres: Their residual rubber oils and strong odor can contaminate the container’s interior.

- Salt: Corrosive properties of salt can damage the container’s metallic components.

- Fertiliser products: High chemical content may corrode or leave residues that are hard to remove.

- Steel: Sharp edges and heavy weight can damage the insulation panels.

- Grain or wheat: Permitted only if packed in FIBCs (Flexible Intermediate Bulk Containers) to prevent contamination and spillage.

- Cement: Fine dust particles can clog vents and adhere to insulation surfaces.

- Sulphur: Highly corrosive and unsuitable due to its chemical reactivity.

- Used batteries: Risk of acid leakage and contamination.

- Used cars: Fluids and fuel residues can pose fire or contamination risks.

- Car batteries: Similar to used batteries — contain acid that can cause permanent damage.

8. What are the benefits of Non Operating Reefer containers?

- Cost Saving

Most shipping lines offer NOR containers at the same cost as a dry container or sometimes even less. This allows shippers to save on freight costs while using a higher-quality container. - Space Priority

In real world operations, getting vessel space can sometimes be challenging, and containers may get shut out. Reefers generally receive higher space priority on vessels, so using NORs can help avoid delays. - Cargo Safety

Thanks to the insulated side panels and T-beam steel flooring, NOR containers provide better protection against physical damage compared to standard dry containers. The cargo stays safer during handling and transport. - Wind and Watertight

Reefers are built to be completely wind & watertight, meaning there’s almost no risk of water leakage inside the container. This adds an extra layer of safety, especially during long voyages or rough weather.

9. What are the limitations of NOR containers?

- Selective Cargo

NOR containers are not suitable for all cargo types. Some commodities can’t be loaded in reefers due to the insulation, flooring, or restrictions from carriers. - Reduced Internal Capacity

The internal space of a reefer is smaller than that of a dry container because of the insulation layers and the reefer machinery, which reduces the available loading volume. - Narrow Door Opening

The door opening width and height are slightly less compared to dry containers, which can make loading and unloading a bit more challenging for larger cargo. - Careful Packing Required

Cargo must be well packed and properly secured inside an NOR. Since there are no lashing rings or securing points inside the reefer, loose cargo can shift and cause damage during transit.

10. What things should be considered when arranging a non operating reefer container?

When preparing a non-operating reefer container (NOR) for shipment, it’s important to focus on the type of cargo, packaging quality, and container condition. The container should be clean, dry, and free from any material that could damage the insulated interior.

Keep in mind that NOR containers usually have lower weight limits than standard dry boxes, as well as less internal space. In many cases, free days for NORs are also shorter, so careful planning is essential. It’s also recommended to maintain proper airflow during loading to prevent condensation or moisture buildup inside the container.

Cargo Considerations for NOR Containers,

- Cargo Type

NOR containers are best suited for non-hazardous, dry cargo such as electronics, textiles, furniture, packaged food, and general consumer goods. Avoid using them for bulk or heavy cargo that could damage the interior walls or floor. - Cleanliness and Odor Control

Cargo should always be clean, dry, and free from strong odors. Any contamination or lingering smell can affect the container’s future use for refrigerated cargo. - Packaging Requirements

All goods should be well packed in cartons or placed on pallets. Avoid loading packages with sharp edges or metal parts, as they can scratch or puncture the insulated panels and reduce the container’s lifespan. - Weight Limit

Be mindful that NORs have a lower payload capacity compared to standard dry containers of the same size. The average load limit is around 3,000 kg/m, so overloading should be avoided to prevent damage or imbalance during transport.

11. What carriers offer non operating reefer containers?

Most major shipping lines that operate reefer containers also provide NOR services as part of their global operations. Details about these services are usually shared through each carrier’s official website or included in their reefer service brochures.

Here’s a list of the leading container carriers that offer NOR services, along with links to their official pages for further information.

- Maersk Line

As the world’s largest reefer operator, Maersk has taken NOR containers shipping beyond just equipment they’ve built full logistics solutions around it. For shippers seeking an integrated approach, Maersk is often the first stop. Their teams understand the fine details of passive cooling and can offer clear guidance on which commodities and trade routes are best suited for NOR containers.

- MSC (Mediterranean Shipping Company)

With one of the biggest fleets of reefer units at sea, MSC is a heavyweight in temperature-controlled logistics NORs included. They play a major role on trades moving agricultural cargo out of South America and Southern Africa. If wide equipment availability and reliable service are your top priorities, MSC is almost always part of the conversation.

- CMA CGM

The French carrier CMA CGM has long been a specialist in reefer transport, especially on the busy fruit lanes from South America. Their strong background in handling temperature-sensitive cargo makes them a natural fit for NOR shipments. For shippers seeking a carrier with deep expertise and consistency in this niche, CMA CGM is a dependable option.

- Hapag-Lloyd

Hapag-Lloyd is known for its precision and strong customer service. They treat NOR as a specific, bookable service not just an add-on. Their reefer and customer service teams are well-trained in identifying when NOR works best, depending on transit times and cargo types. This makes them a great choice for shippers who value clarity and professionalism.

- COSCO / OOCL

As key members of a major global shipping alliance, COSCO and OOCL provide extensive worldwide coverage. Their NOR services are well-established, particularly across the main East–West routes. If your shipments move between Asia, Europe, or the Americas, this group offers a reliable and widely available NOR option.

- ONE (Ocean Network Express)

ONE keeps things simple by listing NOR as its own equipment type in their booking system a small detail that makes a big difference for shippers and forwarders. With a modern reefer fleet and solid route coverage, ONE has earned a reputation as a consistent and transparent provider of NOR services.

- Evergreen

A well-known name across global trade lanes, Evergreen includes NOR containers within its broad service portfolio. They’re a dependable choice, particularly for shipments moving in and out of Asia, backed by a strong network and reliable equipment availability.

- HMM (Hyundai Merchant Marine)

HMM has made significant investments in its reefer fleet and technology. They actively promote NOR as a cost-effective solution within their logistics offerings especially for Transpacific trades. For shippers looking to balance efficiency with savings, HMM is a strong contender.

12. Guidelines for carriage of cargo in non-operating reefers

In August 2017, the Container Owners Association (COA), in collaboration with the Cargo Incident Notification System (CINS), released an important publication titled “Guidelines for the Carriage of Cargoes in Non-Operating Reefer Containers.”

This document, sponsored by the TT Club, provides a detailed framework for shipping lines, operators, and logistics professionals to evaluate which cargo types are suitable for carriage in NOR containers.

The guideline addresses several key areas critical to maintaining container integrity and cargo safety:

- NOR Introduction

- Reefer Container Characteristics

- Dry Cargo in Reefers: Issues to Consider

- Interior Damage Examples

- Refrigeration Machinery & Corrosion Damage

- Refrigeration Machinery Physical Damage

- Cargo Damage Summary

- General Principles for Approving ‘NOR’ Cargo

- Packing of ‘NOR’ Cargo

- Cargoes Not Suitable for ‘NOR’ Use

According to the document, NOR containers originally designed for temperature-controlled shipments can be repurposed for dry cargo transport under specific conditions. However, certain commodities remain restricted due to the risk of corrosion, contamination, odor absorption, and physical damage to the container’s internal insulation and machinery.

For more detailed information, you can refer to the official publication:

📄 [PDF] Guidelines for the Carriage of Cargoes in Non-Operating Reefer Containers (Source: COA / CINS, August 2017)