Table of Contents

The Evolution of Online Container Tracking and Tracing

In an era marked by rapid technological advancements, the logistics industry has undergone a transformative journey, with one of the notable shifts being the widespread adoption of online container tracking and tracing systems. This article explores how individuals and businesses alike have embraced these digital solutions to enhance efficiency, transparency, and overall control in the realm of shipping.

1. The Rise of Digital Tracking:

The days of monitoring shipping container movement only through manual processes and paperwork are over. The introduction of digital tracking technologies, such as Container Tracking, has ushered in a new era of real-time visibility, providing stakeholders with rapid access to critical information about the location and status of their shipments.

2. Seamless Connectivity:

Online tracking technologies, including Container Tracking and tracing, have enabled seamless connectivity across the supply chain. Shippers, carriers, and consignees can stay connected using integrated technologies, resulting in improved communication and collaboration. This interconnection, bolstered by Container Tracking and tracing, has become a key factor in optimizing logistical operations.

3. Real-Time Monitoring:

One of the primary benefits of online tracking is the ability to monitor shipments in real time. Whether crossing oceans or continents, stakeholders may precisely follow their containers’ locations, forecast arrival timeframes, and proactively handle any unforeseen delays.

4. Enhanced Security Measures:

The incorporation of technology into tracking systems has also improved security. With features like geo-fencing, tamper detection, and temperature monitoring, stakeholders can protect their cargo from potential risks and ensure the supply chain’s integrity.

5. Data-Driven Decision-Making:

Online monitoring systems generate a variety of data that can be used for analytics. Businesses can use this data to acquire insights into shipping trends, optimize routes, and make informed decisions that help to reduce costs and improve operational efficiency.

6. Customer Empowerment:

End users are not left out of the digital revolution. Online monitoring has become the norm, giving buyers a greater sense of control and sight over their ordered items. This transparency helps to promote consumer happiness and loyalty.

How Does Container Tracking Work?

Container tracking operates by employing a distinctive identifier to monitor containers as they progress through the supply chain. To ascertain the present location of containers, one can utilize either automatic identification systems (AIS) or container-tracking devices (CTD).

Automatic Identification System (AIS)

The Automatic Identification System (AIS) stands as a crucial advancement in recent years for monitoring container ships. Presently, the International Maritime Organization mandates that most large international container vessels be equipped with AIS. This system involves transponders on ships communicating with each other and terrestrial stations, exchanging details on the ship’s position, speed, and heading. Additionally, AIS provides insights into the cargo container’s status, such as the number, weight of each container, and total shipment weight. This data enhances the efficiency of ship operations and maritime safety. Operating on specific radio wave frequencies, AIS enables real-time tracking of container ships, contributing to a substantial reduction in the time and cost associated with tracking these vessels.

Learn more about Automatic Identification System (AIS)

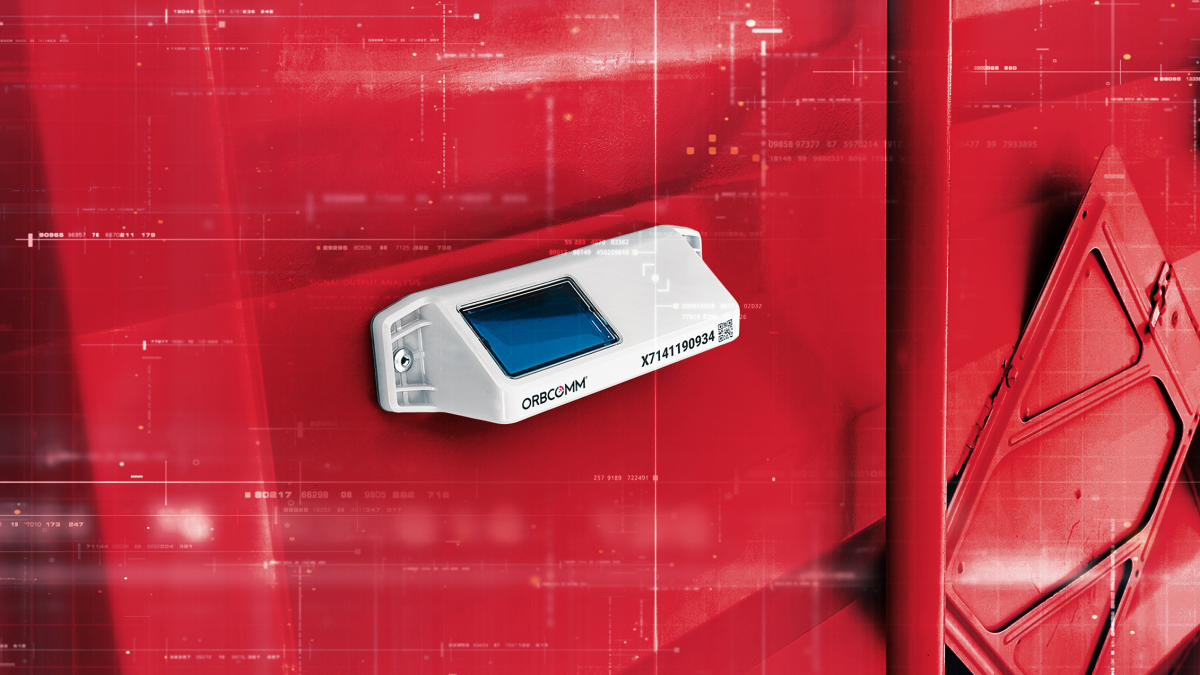

Container Tracking Devices (CTDs)

Container Tracking Devices (CTDs) offer an alternative for container monitoring. Attached externally, CTDs utilize GPS to track container locations and communicate through cellular networks or satellite systems. An advantage of CTDs lies in their ability to track containers in areas without AIS coverage, including smaller vessels and land-based containers. CTDs provide detailed information on container movements, such as loading and unloading times, surpassing the capabilities of AIS. While CTDs boast a longer battery life, their higher cost and the need for a monthly subscription fee distinguish them from AIS transponders.

Which parties need container tracking, and how important is it to them?

01. Shippers:

Why is container tracking beneficial for shippers in their role within the global supply chain? Shippers, whether manufacturers, retailers, or enterprises, must know the exact location and status of their shipments. Utilizing shipping container tracking enables them to improve inventory management, predict delivery times, and increase overall supply chain efficiency.

02. Freight Forwarders:

Freight forwarders arrange the movement of products via various types of transportation. Container tracking enables them to plan and execute logistics operations more effectively, resulting in prompt delivery and fewer disruptions.

03. Shipping Lines/Carriers:

Shipping lines or carriers are responsible for moving cargo across oceans. Container tracking is critical for route optimization, cargo security, and delivering exact arrival times to shippers and consignees.

04. Consignees/Receivers:

Container tracking helps consignees know when their shipments will arrive. This information is useful for optimizing downstream logistics, minimizing wait times, and improving inventory management.

05. Customs Authorities:

To speed customs clearance processes, authorities require reliable information regarding container arrivals and departures. Container tracking ensures regulatory compliance and makes border crossings more efficient.

06. Insurance Providers:

Insurance companies use container monitoring data to identify and manage cargo shipment risks. Real-time information regarding container locations and conditions helps with risk management and claims processing.

07. Port Authorities/Terminal Operators:

Port authorities and terminal operators oversee the movement of containers into and out of ports. cargo tracking is critical for improving port operations, reducing congestion, and assuring efficient cargo handling.

08. Logistics Service Providers:

Third-party logistics firms use container tracking to optimize operations, reduce transit times, and deliver value-added services to their clients.

09. Retailers/End Customers:

Container tracking benefits both retailers and end customers by providing visibility into the supply chain. This openness enables better inventory planning, stock management, and increased customer satisfaction by setting correct delivery expectations.

10. Government Authorities:

Container tracking data is used by government authorities for security, monitoring goods transportation, and verifying compliance with trade regulations. This information helps to ensure the integrity of national borders.

How is container tracking and tracing achieved using different technologies to monitor shipping containers in the supply chain?

01. GPS and Satellite Tracking:

How it works: Containers are equipped with GPS devices or satellite trackers that continuously send their location coordinates. This information is subsequently transmitted to a central tracking system, allowing stakeholders to track the containers’ real-time locations.

Who uses it: GPS and satellite tracking are frequently used by shipping companies, carriers, and logistics providers to provide precise location information.

02. RFID (Radio-Frequency Identification):

How it works: RFID tags are affixed to containers, and these tags emit radio signals that can be detected by RFID readers. As containers move through different points in the supply chain, RFID readers capture and update their location information.

Who uses it: Logistics companies, terminal operators, and some shipping lines utilize RFID technology for container tracking.

03. Telematics and IoT (Internet of Things):

How it works: IoT devices, such as sensors, are embedded in containers to monitor various parameters, including temperature, humidity, and security. These devices transmit data to a central system, providing real-time insights into container conditions.

Who uses it: Shippers, carriers, and companies with specific cargo requirements leverage telematics and IoT for comprehensive container tracking.

What is telematics? — The ultimate guide for IoT, GPS and business

04. Container Line Tracking Systems:

How it works: Shipping companies and carriers frequently offer online tracking systems on their websites. Customers input container numbers or booking references to access real-time updates on the container’s location, transit status, and projected arrival time periods.

Who uses it: Shippers, consignees, and other stakeholders use container line tracking systems to gain quick visibility.

05. Mobile Apps:

-p-800.png)

How it works: Many logistics companies and carriers offer mobile applications that allow users to track containers using their smartphones, and most shipping lines also have their own applications to track and trace containers. These apps typically provide real-time updates and notifications.

Who uses it: Shippers, consignees, and logistics professionals use mobile apps for on-the-go container tracking.

07. Blockchain Technology:

How it works: Blockchain provides a decentralized and secure ledger where container-related information, including tracking data, is recorded. This ensures transparency, data integrity, and a single source of truth for all parties involved.

Who uses it: Various stakeholders in the supply chain, including shipping lines, freight forwarders, and customs authorities, may benefit from blockchain-based container tracking.

06. EDI (Electronic Data Interchange):

How it works: Electronic messages containing container tracking information are exchanged between different parties in the supply chain. This facilitates automated communication and updates on container movements.

Who uses it: Shippers, carriers, freight forwarders, and customs authorities use EDI for efficient and standardized information exchange.