Table of Contents

1. Introduction – Shipping Container Corner Fittings

1.1 Shipping Container Corner Castings: What They Are and Why They Matter ?

Container Corner fittings, also called “corner castings” are one of the most important parts of a shipping container. They are the main structural elements that connect the container to ships, trucks, and trains, making it possible to move goods smoothly between different types of transport. These castings have standard-sized holes that are used for lifting, securing, and stacking containers. They are made from strong, durable steel to handle heavy loads and rough conditions at sea, on the road, or on rail. By allowing containers to be stacked safely and locked in place, corner castings ensure stability and safety during transport, making them a key feature in global trade.

1.2 Container Corner Fittings and Their Key Functions

- They Keep Container Stacks from Collapsing

- They Make Lifting Containers Safe

- They Hold the Container’s Structure Together

- They Ensure Compatibility Across Transport Modes

1.3 What Are the Other Names for Container Corner Fittings?

Container corner castings are known by several other names across the shipping and logistics industry. These alternative terms are often used interchangeably, though “corner castings” remains the most technically accurate term under ISO standards.

- Corner Castings

- Container Corner Blocks

- Container Corners

- ISO Corner Castings

- Corner Connectors

- Shipping Container Blocks

CEDEX CODE of Container Corner Fitting is ” CFG ”

2. Location of Corner Fittings

2.1 General Placement

Every standard shipping container (except 45’ft containers, which may include additional fittings) is fitted with 8 corner castings:

- 4 Corner Fittings at the top corners

- 4 Corner Fittings at the bottom corners

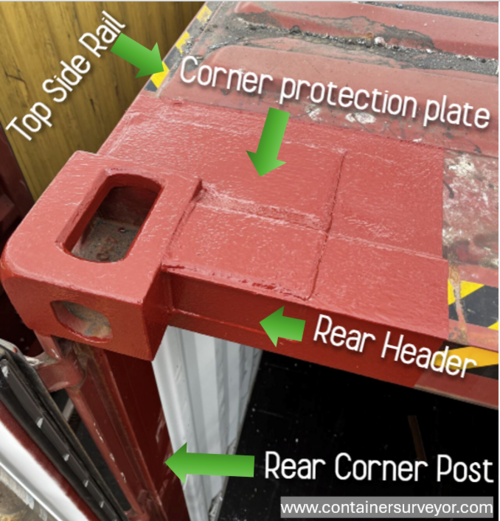

2.2 Top Corner Fittings

Welded To:

- Front Corner Post & Rear Corner Post

- Front Header, Rear Header, Front Header Extension Plate & Rear Header Extension Plate

- Top side rails

Additional Features:

Lashing rings and lashing bars fitted for securing cargo

Corner protection plate attached on the exterior

2.3 Bottom Corner Fittings

Welded To:

- Front Corner post & Rear Corner Post

- Front Sill & Rear Sill

- Bottom side rails

Additional Features:

- Exterior: Doubling Plate and Rail Gusset Reinforcement

- Interior (front): Front Corner Floor Support

- Under Floor: Floor Supporting Angles located beneath the floorboards

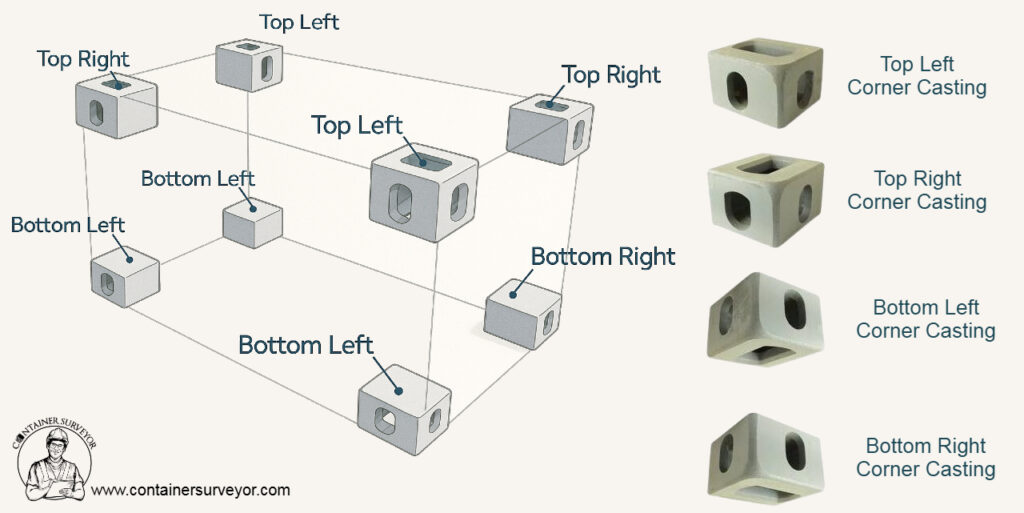

2.4 Types of Corner Fittings

Every ISO container incorporates eight corner castings, separated into four types depending on their location.

- Upper left / Top Left (TL)

- Upper right / Top Right (TR)

- Lower left / Bottom Left (BL)

- Lower right / Bottom Right (BR)

3. Functions of Container Corner Fittings

Corner fittings, also known as corner castings, are one of the most important structural parts of a shipping container. They are found at all eight corners of the container four at the top and four at the bottom and serve as the connection points between the container and handling equipment. Without them, containers could not be safely lifted, stacked, or secured during transport.

Here are the main functions in detail:

- Lifting

Corner castings allow cranes and other lifting equipment to safely handle containers. A crane uses a spreader bar with twist lock mechanisms that fit perfectly into the holes of the corner castings. This enables the container to be lifted vertically without damaging the structure. Whether it’s being loaded onto a ship, taken off a truck, or shifted within a terminal, lifting always depends on these fittings.

- Stacking

Containers are designed to be stacked on top of each other sometimes up to seven or eight high on large vessels. Corner castings make this possible by aligning with twist locks that connect the containers together. The fittings ensure the weight is transferred evenly through the container frame, keeping the stack stable both on ships and in storage yards.

- Securing

During transport, containers must be firmly locked in place to prevent shifting. Corner castings provide the points where containers are fastened to trailers, wagons, or ship decks. Twist locks or lashing rods go through the casting holes, securing the container against movement. This function is essential for safety, especially when vessels are at sea or trucks are moving at high speeds.

4. ISO 1161 Standard – Container Corner Fittings

The International Organization for Standardization (ISO) defines the global standard for container corner castings under ISO 1161. This regulation sets out the exact dimensions, strength, and performance requirements that all ISO-approved containers must meet, ensuring both safety and worldwide compatibility. Standard corner castings generally measure 178 mm x 162 mm x 118 mm, with strict tolerances designed to work seamlessly with lifting equipment and intermodal transport systems.

5. Common Damages and Inspection Points – Corner Castings

5.1 Common Damages – Bureau International des Containers (BIC)

According to BIC, Over time, corner fittings are exposed to constant lifting, stacking, and securing forces. As a result, they can suffer from;

- Enlarged apertures – Repeated wear from twist locks and spreader bars can gradually widen the holes. Oversized apertures may prevent proper securing and increase the risk of container movement or loss at sea.

- Reduced top plate thickness – The top plate of a corner fitting can wear down with use. Once the thickness drops below safe limits, the fitting can no longer bear the required load.

- Cracks and tears – Stress and corrosion may lead to serious cracks, which compromise the strength of the corner fitting.

- Deformations – Impacts or heavy loads can bend or warp the corner fitting. If the deformation exceeds 5 mm from its original plane, it is considered unsafe.

- Missing or broken fittings – In some cases, fittings may be damaged beyond repair or even missing entirely, which makes the container unfit for use.

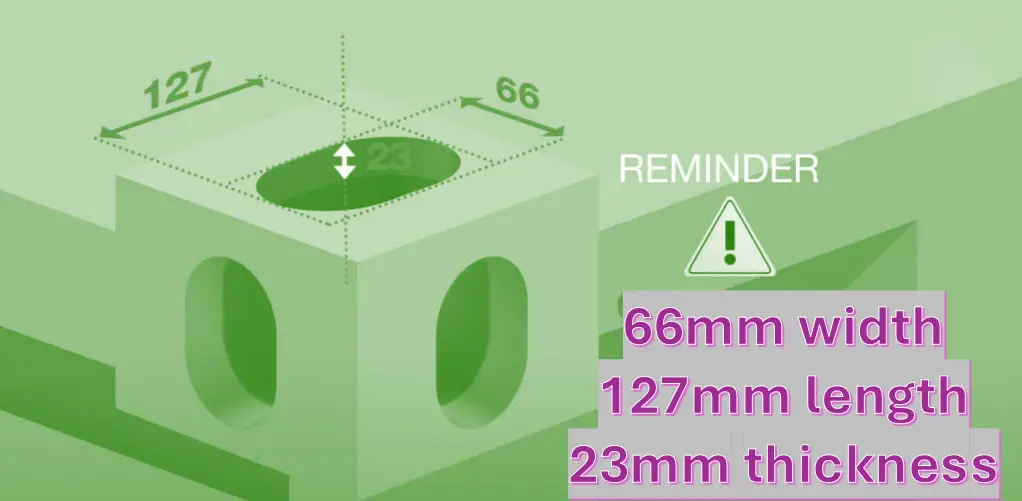

5.2 Inspection Points – (BIC)

To ensure compliance with international safety standards, BIC and the International Convention for Safe Containers (CSC) specify clear criteria for inspecting corner fittings. During inspections, the following points must be checked.

| Inspection Item | Acceptable Limit | Action if Exceeded |

|---|---|---|

| Aperture Width | ≤ 66 mm | Container must be stopped and repaired |

| Aperture Length | ≤ 127 mm | Container must be stopped and repaired |

| Top Plate Thickness | ≥ 23 mm | Replace corner fitting immediately |

| Deformation | ≤ 5 mm from original plane | Container must be taken out of service |

| Cracks or Tears | None acceptable | Immediate withdrawal from operation |

| Missing Corner Fitting | Not allowed | Container must be stopped and repaired |

5.3 Criteria for inspecting corner fittings – IICL

| Inspection Item | Acceptable Limit | Action if Exceeded |

|---|---|---|

| Cracked, loose, torn, broken & missing | None acceptable | Replace the Corner Casting |

| Distortion of the fitting that prevents or restricts proper engagement with lifting or securing device | None acceptable | Replace the Corner Casting |

| Any dimensional change to the aperture that prevents full insertion of a twist lock | None acceptable | Replace the Corner Casting |

| Structural deformation that diminishes the load-bearing cross-section where the twist lock engages | None acceptable | Replace the Corner Casting |

| Defects affecting the integrity of weld connections between the corner fitting and adjoining structural members | None acceptable | Replace the Corner Casting |

| Damage that weakens the load transfer path from the twist lock bearing area to the corner post, side rail, or end rail | Not allowed | Replace the Corner Casting |

| Unauthorized or improper repairs to corner fittings, other than full replacement or certified re-welding to adjoining structures | None acceptable | Replace the Corner Casting |

6. How to Repair Corner Fittings

Replacement Only : Corner Fittings cannot be filled, patched, welded, or reshaped; If damaged, they must be repaired only by full replacement with certified fittings.

Exact ISO Placement Required : New corner fittings must be positioned according to ISO-specified dimensions; No tolerance beyond the defined measurements is permitted, as even a small error can affect handling safety and stacking compatibility.

Follow Standard Repair Procedures : Before repairs, it is important to refer to the general repair principles.

6.1 Container Corner Fitting Replacement

Guidelines

- Cut out the damaged corner fitting with an oxygen acetylene torch.

- Grind all existing welds back to base metal with a disc grinder. (To ensure complete penetration of welds)

- Parts adjacent to corner fittings should have their edges ground to a 45° bevel. ( Do not apply any bevel to the corner fitting )

- Before welding, position the parts with a gap not exceeding 2 mm, and wherever possible, ensure the connections to the corner fitting are fully welded on both sides of the join.

Welding & Welding materials

- All welds must be smooth free of scale, pin and blow holes, and with full penetration.

- Corner fitting welds should be carried out using low-hydrogen rods or wire to reduce the risk of hydrogen embrittlement.

- AWS E7016 and E7018 are the typical low-hydrogen rods used in corner fitting welding.

CEDEX CODE of Container Corner Fitting is ” CFG ”