In general not all shipping companies, leasing companies, container owners have their own container repair procedures and inspection guidelines, therefore they are using general criterion such as IICL, CIC, URIC, CCW. however their main concern is to maintain required strength and repair containers the most economical and simple repair methods, In this topic we will bring you the general idea about the Shipping Container Repair Procedures, different criterion have different procedures that repairer must followed and adhered to. Most of them will cover by this post.

Table of Contents

Proper repair is known as restore the profile of damaged components and surrounding areas as close as possible to original profile, yet repair containers must adhere to applicable requirements of,

- ISO Standards

- International Convention for Safe Containers (CSC)

- Transports Internationaux Routiers, International Road Transport (TIR)

- Classification Society Requirements.

- Capable for transportation of perishable food stuff in accordance with ATP Regulations.

The quality of repair and the safety of workers should not be hampered at any time !!

General Guidelines for Preforming Shipping Container Repairs

- Identify the repair method that will correct the defect satisfactorily with cost-effective manner.

- Always follow the agreed repair criteria.

- Choose proper tools and machines for repair job and place supports and other fixtures as needed.

- Temporarily remove or relocate nearby undamaged parts that may be damage while doing repairs.

- Replacement quality of materials and parts should be equal to original material with strength and thickness (if not, go for higher quality materials) Tip:- Adhere to material decal which attached on interior side of right door panel or right side first panel while choosing materials for repairs, in case materials not available use higher quality materials.

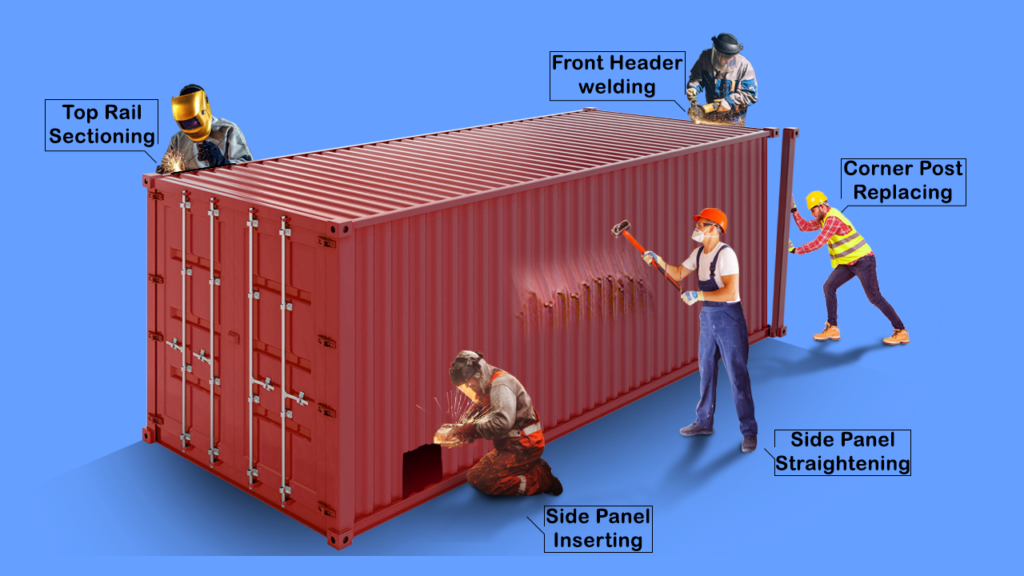

General Repair Procedures

- Welding

- Straightening

- Straighten & Welding

- Inserting and Patching

- Sectioning

- Replacement

Shipping Container Repair Procedure of Welding

Facts of Shipping Container Welding

Welds that are not properly executed can result in safety hazardous, structural failures and costly repairs.

- Welding materials should be equivalent to those applied in original container manufacture.

- Welding Rod / Wire should be minimum yield point of 46kg/mm2 (65000 psi) or greater.

- Qualified welders must perform all welding.

- Welding should adhere to the standards set forth by recognized technical associations like American Welding Society, British Standards etc.

- If welding one side does not fully penetrate the metal both sides of joint must be welded.

- After repairs, welding inspection is required.

Welding Inspection

The inspection should determine that weld is:

- Free of porosity and craters

- Smooth surface (no roughness, weld spatter)

- Dimensionally accurate (including wrap)

- Free of undercutting

Non-destructive Testing Techniques of Weld as follows,

Visual Inspection

Is a non-destructive testing (NDT) weld quality check process.

Magnetic Particle Testing

Liquid Penetrant Testing

Ultrasonic Eddy Current Testing

Learn more about Non-destructive Testing of Welds

Welding Data Table

| STEEL GARDE | DIN NO | AWS NO | WELDING SYSTEM | ELECTRODE/WIRE OR ROD DIAMETER | GASES | ELECTRODES DIN | ELECTRODES AWS |

|---|---|---|---|---|---|---|---|

| MILD STEEL (MS) | 1.0114 | MIG | 1.0-1.2MM | ARGON 82% CO2 18% | UNION K56 | ER70-B6 | |

| HIGH-TENSILE (MTS) | 1.0841 | MIG | 1.0-1.2MM | ARGON 82% CO2 18% | UNION K56 | ER70-B6 | |

| STAINLESS (SS/SUS304) | 1.4301 | MIG TIG | 0.8 – 1.0 MM 1.0 /2.4 MM | ARGON 97.5% ARGON 100% | 1.4370 1.4316 | E307 E308L | |

| CORTEN A | 8559 | 5.18 | MIG | A – 1.0 -1.2 MM WIRE (use with 4.5mm & Thicker Steel) B – 0.9 MM WIRE (use with 1.9mm – 4.5mm Steel) C – 0.6 MM WIRE (use with up to 1.9mm Steel) | ARGON 80% CO2 20% | 1913 | A5.1 |

TIG WELDING – is known as tungsten inert gas welding

What is Tack Weld ?

Tack weld is a singe bead of weld or few beads to hold components in position temporarily prior to permanent welding, a bead of weld should be less than 25mm

Note:- Tack welding is used to comply with specific TIR requirements (Weld nuts to bolts on door)

What is Skip Weld ?

A linear series of weld beads separated from the next bead by an unwelded length, each weld bead is approximately 25mm or more in length. the sum of the length of one bead plus the unwelded distance to the next bead is called pitch.

What is Butt Welding

Two pieces of metal are placed end-to-end without overlap and then welded along the joint.

What is Continuous Weld ?

Unbroken weld bead used to seal two components together.

What is Common Weld ?

A single weld joining together two adjacents inserts or sections on one side of each

Two Rules of Shipping Container Welding

- The maximum length of any crack, fracture, cut or tear that may be welded is 200mm and the maximum width of separation is 5mm, if exceeds decide for other repair options.

- A crack, fracture, cut or tear may not be welded if it penetrates more than 50% of the height of a rail, crossmember or other horizontal structural component.

Straightening

What is shipping container Straightening ?

Restore a damaged component as close as possible to its original shape by using methods of mechanically or hydraulically.

What are the Straightening methods ?

01. Mechanically

Straighten any dents, buldge (in/out), push(inwards/outwards/upwards) or other distortions to the component by using a a flat hammer or mallet or jack.

02. Hydraulically

Straighten any dents, buldge (in/out), push(inwards/outwards/upwards) or other distortions to the component by using Hydraulic Jack

03. Straightening including hot work

In this case heat will applied to straighten the components, damaged area and must not be heated beyond a dull cherry-red color, corresponding to approximately 650°C (1200°F)

Aware these while performing straightening

- Repair must not affect of the component’s structural integrity or impede its safe operation.

- Repair must be cosmetically acceptable.

- Any component’s paint coating is harmed as a result of the repair, required clean and coat the component.

Importance of Backing Plate ( Backing Device )

Backing Plate is heavy flat object which may be shaped to fit into the corrugation.

While straighten panel by flat hammer always use backing device, if fails multiple hammer marks may be left in the panel. and it weakens the panel, this results in an unacceptable cosmetic condition.

Shipping Container Repair Procedure of Straightening & Welding

A component repaired by a combination of straightening and welding.

Shipping Container Repair Procedure of Inserting and overlapping Patching

Components which cannot repaired by straightening or welding as a next option as a installing an insert or patch.

INSERT repair basically restore a damaged component to its original size, cutting out a portion of the component that is less than the full-profile section, but shape and strength must be maintained or The replacement part is called an insert. ( cutting out a portion of the component should less than the full-profile section ) each components have their own limitations therefore follow the instructions of your repair guidelines.

PATCHING repair is restore a damaged component slightly larger than the material being removed, its edges overlap the parent material, its edges overlap the parent material.

Patching is not allowed for every component therefore follow the instructions of your criteria, patching can be seen on side front and roof panels, header extension plate etc.

Things that you want to know about shipping container Insert

- DE attach or free-up any adjoining components while cutting to protect against burning damage.

- Replacement material must have the same profile as the original if not use higher quality material.

- Inserts must be fitted flush with the existing component

- Inserts should be fabricated to allow no more than 2mm clearance between adjoining surfaces.

- Inserts should be flushed with the adjoining area.

- If repairing a frame components, bevel adjoining surfaces for components to a combined 60°

- angle (30° angle on each side of the joint)

- When an insert extends to a corner fitting,the edge of the insert should be beveled to a 45° angle, this is not applicable for casting.

Things that you want to know about shipping container overlapping Patching

- Patches should overlap the existing panel on the exterior by 13 mm.

- While installing a patch, grind the existing panel to bare metal 20 mm (3/4 in) from the cut edges on the exterior side.

Shipping Container Repair Procedure of Sectioning

Components which cannot repaired by straightening or welding as a next option as a installing an insert or patch. restore a damaged component to its original size, shape and strength by cutting out a portion of the component that extends through its full profile.shape and strength must be maintained, each components have their own limitations therefore follow the instructions of your repair guidelines.

Things that you want to know about shipping container Section

- DE attach or free-up any adjoining components while cutting to protect against burning damage.

- Replacement material must have the same profile as the original if not use higher quality material.

- Section must be fitted flush with the existing component

- Section should be fabricated to allow no more than 2mm clearance between adjoining surfaces.

- Section should be flushed with the adjoining area.

- If repairing a frame components, bevel adjoining surfaces for components to a combined 60°

- angle (30° angle on each side of the joint)

- When an Section extends to a corner fitting,the edge of the section should be beveled to a 45° angle, this is not applicable for casting.

- if necessary, apply sealant along interior seams.

Shipping Container Repair Procedure of Replacement

To remove an entire damaged component and weld or attach a complete new component of the original size and strength.

Things that you want to know about Replacement

- Bevel the edges to be welded to adjacent components to a 45° angle

- Allow no more than 2mm (5/64 in) clearance between adjoining edges.

- Ensure that the replacement that ISO dimensions tolerances are maintained.

Disclaimer: The views expressed by the authors in this article do not necessarily reflect the views of CONTAINER SURVEYOR. Data and charts, if utilized, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and CONTAINER SURVEYOR do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.