1. What Is a Super Heavy Container ?

A Super Heavy Container looks almost the same as a regular shipping container but is built to carry significantly heavier loads. These containers can hold over 10,000 kilograms more than standard ones. Due to their increased weight, they must display a warning label to alert workers such as crane operators and transport crews ensuring safe handling. This helps prevent accidents, equipment damage, and injuries.

2. Why Are Super Heavy Containers Used ?

Super heavy containers are usually used for carrying very heavy cargo like machinery, metal coils, cement, or granite. Their total weight goes beyond the standard limits, which is why they need extra care during handling and transport.

3. How to Identify a Super Heavy Container

3.1 Look for Warning Labels or Stickers

Super heavy containers usually have warning label that say things like “Super Heavy” and “Caution: Heavy Load“; These labels are often found on the container doors or side panels and are usually bright-colored (yellow or red) to grab attention.

3.2 Check the Container’s Gross Weight

Every container has a CSC plate (safety approval plate) or markings that show Tare Weight (empty container weight) Payload (maximum cargo weight) Gross Weight (total weight when fully loaded) If the gross weight is higher than the standard limit (usually over 30,480 kg or 67,200 lbs), it’s a super-heavy container. (The weight information is also displayed on the shipping container door)

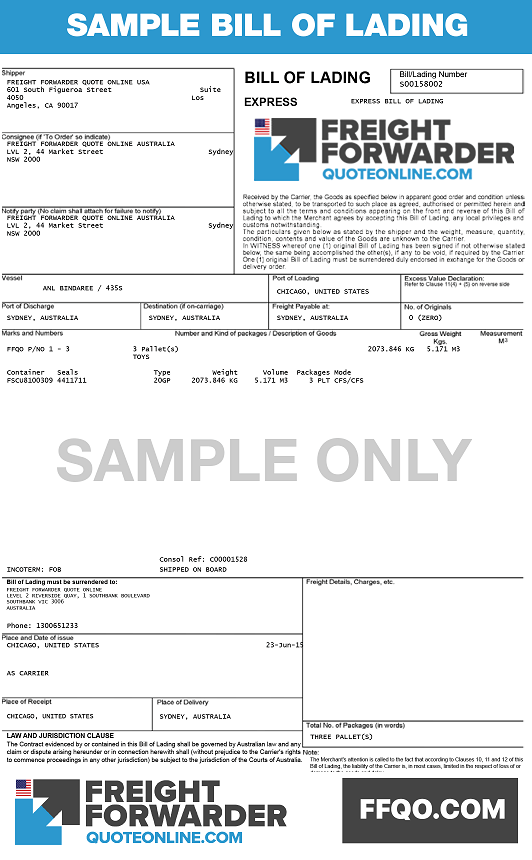

3.3 Review the Shipping Documents

The Bill of Lading, Packing List, or Cargo Manifest will mention the total weight. If the cargo includes heavy items like metal, machinery, granite, or cement, it’s likely to be classified as super heavy.

The Bill of Lading, Packing List, or Cargo Manifest will mention the total weight. If the cargo includes heavy items like metal, machinery, granite, or cement, it’s likely to be classified as super heavy.

Common Types of Cargo in Super Heavy Containers

Super heavy containers are used when cargo is too dense or heavy for a regular container. These are not oversized in size, but their weight is much higher. The cargo inside often looks normal but is extremely heavy due to its material.

Below are some common examples of cargo that usually require super heavy containers;

- Heavy Machinery

- Cement or Concrete Bags

- Metal Coils and Steel Rolls

- Granite, Marble, and Stone Blocks

- Liquid Cargo in Drums or Tanks

- Industrial Spare Parts or Equipment

Handling and Safety Tips

- 1. Always Check the Labels – Look for “Super Heavy” or “Heavy Load” stickers,These labels are placed to warn operators that the container is not standard and needs special attention.

- 2. Read the Container Weight Markings – Check the container’s CSC plate (usually on the door), note the gross weight—if it’s above 30,480 kg (67,200 lbs), it’s a super heavy container. Make sure the equipment being used can safely handle this weight.

- 3. Use the Right Equipment – Use stronger cranes, forklifts, or reach stackers designed for heavy lifting, Double-check that the equipment is certified and in good condition before starting work.

Never treat a super heavy container like a regular one. Its weight adds risk, so careful planning, the right equipment, and trained people are key to safe handling.

Differences Between Standard and Super Heavy Containers

While standard containers and super heavy containers may look almost the same from the outside, they are very different when it comes to weight and usage. Below is a simple comparison to help you understand the key differences.

1. Weight Capacity

| Feature | Standard Container | Super Heavy Container |

|---|---|---|

| Typical Gross Weight | Up to 30,480 kg (67,200 lbs) | Over 30,480 kg, sometimes much more |

| Payload Capacity | Around 28,000 kg (depending on type) | Can go 10,000 kg or more above standard |

2. Type of Cargo

| Feature | Standard Container | Super Heavy Container |

|---|---|---|

| Cargo Examples | Clothes, electronics, furniture, food | Machinery, cement, steel coils, granite |

| Density | Light to medium | Very dense or compact but heavy |

3. Handling Requirements

| Feature | Standard Container | Super Heavy Container |

|---|---|---|

| Handling Equipment | Regular forklifts or cranes | Heavy-duty cranes or equipment |

| Labeling | No special warning | Marked with “Super Heavy” or caution signs |

Labeling and Warnings to Watch For

Super heavy containers may look like regular containers, but they come with special labels and warnings to alert workers that the container carries extra weight and must be handled with care. These labels are very important for safety and accident prevention.

- 1. “Super Heavy” Label

- This is the most common warning.

- It is usually placed on the container door or side wall.

- Tells crane operators and ground staff that the container is not standard and needs special handling.

1. “Super Heavy” Label

- This is the most common warning.

- It is usually placed on the container door or side wall.

- Tells crane operators and ground staff that the container is not standard and needs special handling.

2. “Caution: Heavy Load” or Similar Warnings

- Some containers may have general warnings like:

- “Heavy Load”

- “Do Not Lift Without Approval”

- “Check Weight Before Handling”

Challenges in Transporting Super Heavy Containers

Moving super heavy containers isn’t as simple as transporting regular ones. Their extra weight brings special challenges that require careful planning, stronger equipment, and extra safety checks. Here are some common problems faced during transport;

Watch as two rotator crews tackle a challenging Super Heavy Container rollover. This 40′ container tipped onto a generator base, requiring precision lifting to avoid damage to nearby structures.

- 1. Limited Lifting Equipment

Challenge: Not all cranes or forklifts are built to lift super heavy loads. - Why it matters: Using the wrong equipment can cause machine failure, cargo damage, or accidents.

- Solution: Always check if the equipment is rated for the container’s gross weight.

- 2. Road and Bridge Weight Restrictions

Challenge: Roads, highways, and bridges often have maximum weight limits.

Why it matters: A super heavy container might need special permits or restricted routes.

Solution: Plan the transport route in advance and apply for any necessary approvals.

- 3. Uneven Load Distribution

Challenge: If cargo inside the container is not evenly spread, it can cause imbalance.

Why it matters: This can lead to tipping, uneven lifting, or damage to trailers and forklifts.

Solution: Always check cargo balance before lifting or transporting.

- 4. Limited Port Facilities

Challenge: Some ports or container yards may not have the tools or space to handle very heavy loads.

Why it matters: This may lead to delays or rejections at certain terminals.

Solution: Confirm with the port in advance if they can accept and handle super heavy containers.

- 5. Increased Transport Costs

Challenge: Super heavy containers often need special equipment, permits, and routes.

Why it matters: All these factors increase the total cost of transportation.

Solution: Budget for extra expenses when shipping very heavy cargo.

- 6. Higher Risk of Accidents

Challenge: The more a container weighs, the more risk it carries during lifting, moving, or stacking.

Why it matters: If not handled properly, it can damage equipment or injure workers.

Solution: Only use trained operators and follow all safety rules carefully.

- 7. Delays Due to Special Handling

Challenge: Super heavy containers take more time to move because of careful handling, safety checks, and documentation.

Why it matters: This can lead to missed shipping schedules or late deliveries.

Solution: Allow extra time in your shipping plan for handling and inspections.

- 8. Delays Due to Special Handling

Challenge: Super heavy containers take more time to move because of careful handling, safety checks, and documentation.

Why it matters: This can lead to missed shipping schedules or late deliveries.

Solution: Allow extra time in your shipping plan for handling and inspections.

Shipping Container Markings Explained – Learn the meaning behind container labels weight limits, hazard decals, CSC plates, and more. Essential for logistics pros and shippers.