Table of Contents

What are the purposes of Shipping Container Markings, Decals, Labels and Stickers ?

Shipping Container Decals, Shipping Container Labels, Shipping Container Stickers, and Shipping Container Markings all serve similar purposes by providing identification, information, branding signage, and warnings. However, they differ slightly in their usage and application. Decals are often used for durable and long-term markings, labels focus on concise and detailed information, stickers are versatile and suitable for temporary or supplementary needs, and markings provide standardized, essential details such as weight limits, codes, and ownership information. Together, these components ensure clear communication and compliance for shipping containers in various operations.

What is the Shipping Container Markings ?

These are permanent or semi-permanent identifiers painted, stenciled, or printed directly onto the surface of a shipping container. They provide standardized information about the container’s ownership, specifications, and compliance with international regulations.

Purpose – To ensure proper identification, handling, and tracking of containers during transport and storage.

Examples of Shipping Container Markings

ISO Code: A unique identifier for the container type (e.g., “22G1” for a 20-foot dry container).

Owner/Operator Code: Identifies the company that owns or leases the container (e.g., “MAEU” for Maersk).

Container Number: A unique serial number for the container.

Tare Weight: The weight of the empty container.

Max Gross Weight: The maximum allowable weight of the container including cargo.

Size and Type Codes: Indicates the container’s dimensions and type (e.g., “20GP” for a 20-foot general-purpose container).

What is the Shipping Container Decals ?

Decals are durable, adhesive labels applied to the surface of a shipping container. They are typically made of weather-resistant materials like vinyl or polyester and are used for branding, warnings, or regulatory compliance.

Purpose – To provide long-lasting information or warnings that can withstand harsh environmental conditions.

Examples of Shipping Container Decals

Company Logos: Branding decals for shipping lines or leasing companies.

Hazard Warning Decals: Indicate dangerous goods (e.g., flammable, toxic, corrosive).

Handling Instructions: Decals like “This Side Up” or “Fragile.”

What is the Shipping Container Labels ?

Labels are adhesive pieces of paper, plastic, or other materials attached to a container to provide specific information about the cargo, handling instructions, or regulatory compliance. They are often temporary and can be removed or replaced.

Purpose – To communicate critical details about the container’s contents or handling requirements.

Examples of Shipping Container Labels

Hazard Labels: Indicate dangerous goods (e.g., flammable, toxic).

Cargo Labels: Provide details about the contents, such as weight, destination, or handling instructions.

Barcode Labels: Used for tracking and inventory management

What is the Shipping Container Stickers ?

Stickers are similar to labels but are often more informal and used for temporary or additional information. They are typically smaller and less durable than decals or labels.

Purpose – To provide quick, temporary information or warnings.

Examples of Shipping Container Stickers

Custom Stickers: Used for promotional purposes or to indicate special handling.

Inspection Stickers: Applied after a container has been inspected.

Tamper-Evident Stickers: Used to show if a container has been opened or tampered with.

In summary:

Shipping Container Markings are permanent identifiers.

Shipping Container Decals are durable adhesive labels for branding or warnings.

Shipping Container Labels are temporary or semi-permanent adhesive pieces for specific information.

Shipping Container Stickers are informal, often temporary adhesive pieces.

Where to find Shipping Container Markings, Labels, Decals and Stickers ?

Shipping container labels, decals, stickers, and markings are placed in specific locations on the container for visibility and compliance.

Shipping Labels can be found both inside and outside the container, often near doors or on interior walls. They provide handling instructions, safety guidelines, or regulatory details.

Shipping Decals are typically applied to the external panels of the container. They are larger and used for branding, identification, or compliance purposes, such as company logos or certification details.

Shipping Stickers can be placed anywhere on the container, depending on their purpose. They are commonly found near inspection areas, identification points, or temporary information sections.

Shipping Container Markings are permanent and stenciled or painted onto the container’s exterior, including the side panels and doors. These markings display essential details like the container number, owner code, and regulatory compliance information.

Who uses shipping container stickers, decals, labels, and markings, and how do they help in safety, compliance, and operations?

Various stakeholders in the shipping and logistics industry rely on stickers, decals, labels, and markings for different purposes, ensuring safety, compliance, and operational efficiency

01. Shipping Lines, Leasing Companies & Container Owners

Shipping lines and container owners use various markings, decals, and labels to establish ownership, promote branding, and ensure compliance with international regulations. Logos and company decals help identify the operator or leasing company, making it easier to track and manage containers. Container number markings serve as a unique identifier, allowing for efficient record-keeping and tracking throughout the supply chain. CSC safety plates provide essential structural and inspection information, ensuring the container meets safety standards for transport and stacking. These markings and labels play a crucial role in maintaining accountability and regulatory compliance in global shipping operations.

02. Freight Forwarders & Logistics Companies

Freight forwarders and logistics companies rely on specific markings, labels, and decals to ensure proper cargo handling, stacking, and transportation. Weight limit markings indicate the maximum load capacity, helping prevent overloading and structural damage. High cube warnings alert handlers that the container is taller than standard units, requiring extra caution during stacking and transport. “Empty Lift Only” labels inform crane operators and forklift drivers that the container should not be lifted when loaded, reducing the risk of accidents and equipment damage. These identifiers play a vital role in maintaining safety and efficiency throughout the shipping process.

03. Port Authorities & Customs Officials

Proper cargo handling, stacking, and transportation are critical in shipping operations, and specific markings, labels, and decals help ensure these processes are carried out safely and efficiently. Weight limit markings indicate the maximum allowable load, preventing overloading that could damage the container or compromise transport safety. High cube warnings signal that the container is taller than standard units, requiring special handling to avoid clearance issues and improper stacking. “Empty Lift Only” labels inform operators that the container must not be lifted while loaded, reducing the risk of accidents and structural failures. These identifiers play a crucial role in maintaining safe and organized container movements.

04. Repair & Maintenance Teams

Repair and maintenance teams rely on specific labels and markings to ensure proper materials and methods are used during container repairs. Labels such as “For Repair Use Corten or Equivalent Only” indicate that only weather-resistant Corten steel or an approved equivalent should be used for structural repairs, maintaining the container’s durability and compliance with industry standards. Steel floor markings help technicians identify the type of flooring material, ensuring appropriate repair techniques and materials are applied. These labels and markings play a crucial role in maintaining container integrity, prolonging lifespan, and preventing improper repairs that could compromise safety.

05. Cargo Handlers & Warehouse Staff

Cargo handlers and warehouse staff depend on specific labels and markings to follow safety precautions and handling guidelines. Caution labels such as “Cargo Might Fall Out When Door Opens” warn workers of potential hazards when opening the container, helping to prevent accidents and injuries. Electric shock hazard markings indicate the presence of electrical components, ensuring that personnel take necessary precautions during maintenance or modifications. These warnings play a vital role in maintaining a safe working environment, reducing risks, and ensuring that containers are handled properly throughout their journey.

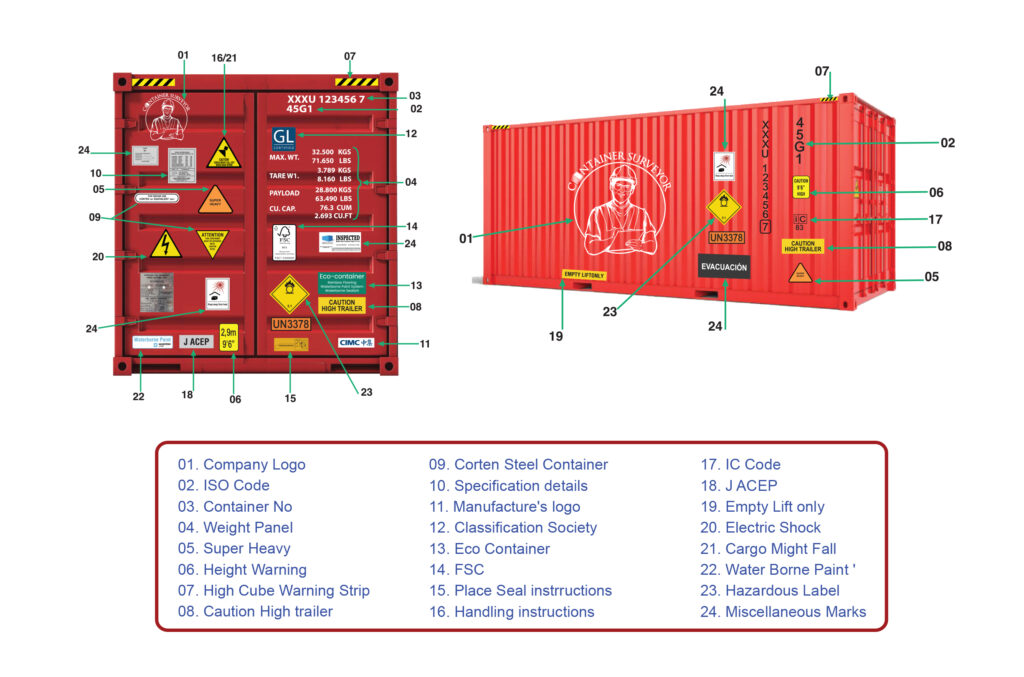

01. Company Logos

These logos help people quickly identify the container, especially in busy places like ports or during transport. They are printed on durable materials to survive tough conditions like rain, sun, or saltwater. Along with the logo, other important details like tracking numbers or safety warnings might also be included. Beyond just identification, logos help companies promote their brand, as containers travel globally, acting like moving advertisements. This makes logos a key part of both practical use and branding for shipping containers.

02. Shipping Container ISO Code

The ISO code on a shipping container is a standardized system used to identify the type, size, and characteristics of the container. Established by the International Organization for Standardization (ISO), these codes ensure consistency and clarity in global shipping operations.

The ISO code is a combination of letters and numbers printed on the container, usually near the company logo or other markings.

It provides essential information about the container, such as its category, size, and type (e.g., dry storage, refrigerated, open-top, or tank container).

03. Container Owner/Operator Code and Container Number

The Owner/Operator Code and Container Number are key identifiers on a shipping container, helping to track and manage containers in the global shipping industry.

04. Shipping Container Weight Panel

The Weight Panel on a shipping container is a critical marking that provides important information about the container’s weight limits. It ensures safe handling, loading, and transportation of the container. Key Information in a Weight Panel, Tare Weight (TARE), Payload (PAYLOAD or NET WEIGHT), Gross Weight (GROSS or MAX GROSS), Maximum Stacking Weight.

05. Super Heavy

Shipping Container Super Heavy markings on a shipping container indicate that the container is carrying cargo with an exceptionally high weight, often close to or exceeding standard weight limits. These markings are crucial for ensuring safe handling, transport, and stacking. Ports, shipping lines, and trucking companies use this label to take extra precautions, such as using specialized equipment or adjusting load distribution on vessels and trailers. Without proper awareness, heavy containers can cause accidents, structural damage, or imbalances during transit.

06. Height Warning

Shipping Container Height Warning markings on a shipping container indicate that the container is taller than standard units, usually exceeding 8 feet 6 inches (high-cube containers are typically 9 feet 6 inches). These warnings are essential for preventing collisions with low bridges, tunnels, or overhead structures during transportation. They alert truck drivers, crane operators, and port workers to handle the container with extra care, ensuring safe loading, stacking, and movement.

If these height warnings are ignored, accidents can happen—like a container hitting a bridge or overpass. This can damage the truck, the container, and even the road or bridge. It can also cause traffic jams, delays in delivery, and put people’s safety at risk.

07. High Cube Warning Strip

Shipping Container High Cube Warning Strip is a reflective marking, usually a yellow or red strip placed on the top corners of high-cube containers (which are 9 feet 6 inches tall instead of the standard 8 feet 6 inches). This strip serves as a visual warning to truck drivers, crane operators, and port workers, helping them identify taller containers and avoid clearance issues under bridges, tunnels, and low-hanging structures. It enhances safety during transport and stacking operations.

In this incident, the container struck a bridge that clearly displayed a low clearance of 4.0 meters. A high-cube (HQ) shipping container is 9 feet 6 inches tall, which is approximately 2.9 meters. When placed on a trailer—usually around 1.3 to 1.5 meters high—the total height easily exceeds 4.2 meters.

This accident shows clear negligence in checking and following height restrictions. The container had warning markings indicating its extra height, but they were either ignored or not properly considered. This kind of oversight can lead to serious damage, not only to the container and vehicle but also to public infrastructure, while also putting lives at risk.

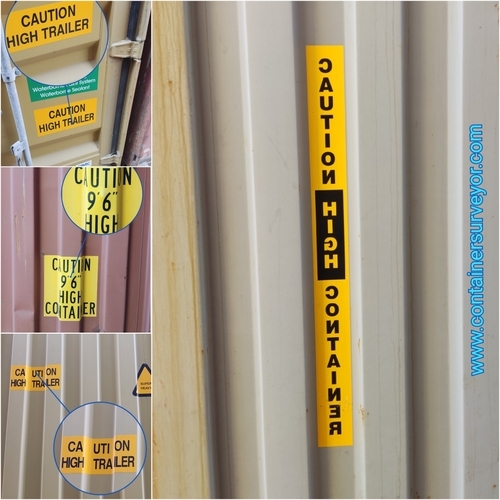

08. Caution High Trailer

Shipping Container Caution High Trailer markings are placed on high-cube containers or trailers that exceed standard height limits, typically over 13 feet 6 inches when mounted on a chassis. These warnings help prevent clearance issues when passing under bridges, tunnels, and overhead structures. They alert drivers, warehouse staff, and port workers to take extra care during transportation, stacking, and loading to avoid accidents or damage.

09. Corten Steel Container & This Container Must Be Repaired Only with Corten Steel

A Corten Steel Container is a shipping container made from Corten steel, a weathering steel known for its high resistance to rust and corrosion. This material forms a protective oxide layer when exposed to the elements, making it ideal for long-term outdoor use and harsh marine environments. Corten steel containers are more durable than regular steel containers, requiring less maintenance and offering a longer lifespan, making them a preferred choice for shipping, storage, and conversions into homes or offices.

The marking “This Container Must Be Repaired Only with Corten Steel” indicates that any repairs or structural modifications to the container must be done using Corten steel only. Since Corten steel has unique weather-resistant properties, using different materials like regular steel could compromise the container’s durability, strength, and resistance to corrosion. This ensures the container maintains its original quality, longevity, and compliance with shipping standards.

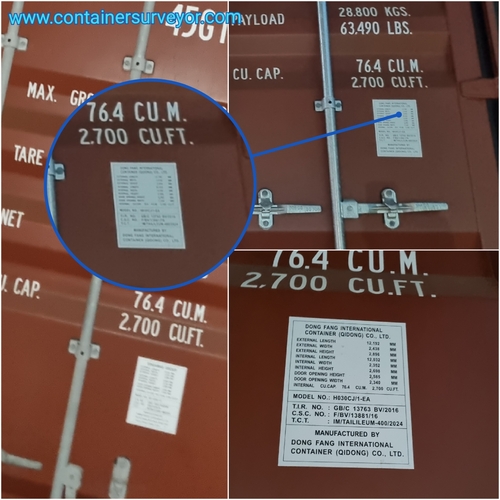

10. Specification Details

Specification Details of a shipping container provide essential information about its dimensions, weight capacity, and construction materials. These details are crucial for logistics planning, ensuring proper handling, stacking, and transportation. Key specifications include:

Material – Usually Corten steel for durability.

External Dimensions – Length, width, and height (e.g., 20ft or 40ft, standard or high-cube).

Internal Dimensions – Usable space inside the container.

Door Opening Size – Width and height of the container doors for loading access.

Tare Weight – The empty weight of the container.

Maximum Gross Weight (MGW) – The total allowable weight, including cargo.

Payload Capacity – The maximum cargo weight the container can carry.

11. Manufacturer’s Logo

The Manufacturer’s Logo on a shipping container represents the company that originally built the container. It is usually displayed on the side or front of the container and may include the company name, logo, or branding. This marking helps identify the manufacturer for quality assurance, warranty claims, and compliance with industry standards. It also provides traceability in case of repairs or modifications needed during the container’s lifespan.

12. Classification Society Mark

A Classification Society Mark on a shipping container indicates that the container has been inspected and certified by an internationally recognized classification society such as Lloyd’s Register (LR), Bureau Veritas (BV), or the American Bureau of Shipping (ABS). These marks confirm that the container meets industry safety, structural integrity, and durability standards. The certification ensures compliance with regulations like the Convention for Safe Containers (CSC), making the container fit for global transport and heavy-duty use.

13. Eco-Container Bamboo Flooring

Eco-Container Bamboo Flooring refers to the use of bamboo instead of traditional hardwood for the container’s floor. Bamboo is a sustainable, fast-growing, and environmentally friendly material that offers high strength, durability, and moisture resistance. Compared to conventional plywood floors made from tropical hardwood, bamboo flooring helps reduce deforestation while maintaining the necessary structural integrity for heavy cargo loads. It is commonly used in eco-friendly shipping containers to promote greener logistics and reduce environmental impact.

14. Forest Stewardship Council Certification

The Forest Stewardship Council (FSC) Certification is a globally recognized certification that ensures the wood used in products, including shipping container flooring, comes from responsibly managed forests. FSC-certified wood is harvested in a way that preserves biodiversity, benefits local communities, and supports sustainable forestry practices. Containers with FSC-certified bamboo or plywood flooring help reduce environmental impact and promote eco-friendly shipping solutions. This certification is often found on eco-containers that prioritize sustainability and responsible resource use.

15. Place Seal Here

The “Place Seal Here” marking on a shipping container indicates the designated spot where a security seal should be applied after loading. Security seals are used to prevent unauthorized access and tampering during transportation. These seals are typically placed on the container’s locking bars or door handle and must be intact upon arrival at the destination. This marking ensures that logistics teams, customs officials, and transport operators correctly secure the container for safe and compliant shipping.

The Use Of Seals In Shipping and Transportation

16. Handling Instructions.

Handling Instructions on a shipping container provide guidelines for safe transportation, lifting, and storage to prevent damage and ensure safety. These markings or labels inform workers, crane operators, and transporters about specific precautions.

17. IC Code

The IC Code, standing for “InterContainer,” is an international railway safety certification marking found on shipping containers. This code signifies that a container has been approved for rail transport by a specific railway authority. The two digits following the “IC” denote the certifying national railway organization

18. J ACEP

J ACEP (Approved Continuous Examination Program) is a marking found on shipping containers, indicating that the container is part of an ongoing inspection program under the Convention for Safe Containers (CSC). Instead of requiring a periodic CSC safety inspection every 30 months, containers under ACEP are regularly checked during normal operations by certified professionals.

The “J” in J ACEP may refer to a specific country or organization that issued the ACEP approval. This marking ensures that the container remains structurally sound and safe for transport without needing separate periodic inspections.

19. Empty Lift Only

“Empty Lift Only” is a safety marking on a shipping container that indicates it should only be lifted when empty. This is typically found on specialized or lightweight containers that are not designed to withstand the stress of lifting while loaded. Ignoring this instruction can lead to structural damage, accidents, or equipment failure.

This marking helps crane operators, forklift drivers, and logistics personnel handle the container safely and correctly, ensuring compliance with weight and lifting restrictions.

20. Electric Shock Black & Yellow Triangle

The Electric Shock Black & Yellow Triangle is a standard warning symbol used to alert people to the risk of electric shock or high voltage. In the context of shipping containers, you’ll typically find this label on reefer containers (refrigerated containers) or any container with electrical equipment.

The black lightning bolt inside a yellow triangle is a universal sign for electrical hazard, warning workers to handle the container with care and avoid tampering with electrical components unless properly trained. It helps ensure safety during handling, maintenance, and transport.

21. Caution! Cargo Might Fall Out When Door Opens Sticker

Handling Instructions on a shipping container provide guidelines for safe transportation, lifting, and storage to prevent damage and ensure safety. These markings or labels inform workers, crane operators, and transporters about specific precautions.

The “Caution! Cargo Might Fall Out When Door Opens” sticker is a safety warning placed on container doors to alert anyone opening them that the cargo inside may have shifted during transport.

This sticker is especially important for containers that carry loose, unstrapped, or unstable cargo, as opening the doors without care could result in injury or damage from falling items. It reminds port workers, truck drivers, and warehouse staff to open doors slowly and cautiously, and to stand to the side—not directly in front—when doing so.

22. Waterborne Paint System

The Waterborne Paint System is an eco-friendly coating method used on shipping containers, where water-based paint replaces traditional solvent-based paint. This system greatly reduces the release of volatile organic compounds (VOCs), making it safer for the environment and for workers applying the paint.

Despite being water-based, these paints are highly durable, offering strong protection against rust, corrosion, and harsh weather conditions. Containers painted with a waterborne system are often part of green or eco-container initiatives, promoting sustainability in global shipping.

23. Hazardous Labels & UN Labels

Hazardous Labels and UN Number Labels are critical safety markings placed on shipping containers that carry dangerous or hazardous goods, in compliance with international regulations like the IMDG Code (International Maritime Dangerous Goods Code).

Hazardous Labels

These are diamond-shaped symbols, usually with bold colors and pictograms that indicate the type of hazard the cargo presents. Common examples include:

- Flammable (Class 3) – Red label

- Corrosive (Class 8) – Black and white label

- Toxic (Class 6) – White label with skull and crossbones

- Explosive (Class 1) – Orange label

- Gas (Class 2) – Green (non-flammable), Red (flammable), or Yellow (toxic) labels

Dangerous goods classes and hazard labels

Each label tells port workers, transporters, and emergency responders how to safely handle the container and what risks are involved.

UN Number Labels

The UN Number is a 4-digit code that identifies the exact substance inside the container (e.g., UN 1203 for gasoline, UN 1017 for chlorine gas). These numbers are displayed on orange panels or in conjunction with the hazard label and are used for:

- Identifying the chemical

- Emergency response

- Customs and regulatory compliance

Together, these labels ensure safety, proper handling, and legal transport of hazardous materials across countries and transport modes.

24. Miscellaneous Markings

Miscellaneous Markings on a shipping container refer to various temporary or operational stickers and labels that provide important handling, safety, or regulatory information. These are usually applied for specific shipments and removed afterward. Common types include:

Shipper’s Cargo Handling Instructions: Custom stickers or labels placed by the shipper to guide safe handling—e.g., “Do Not Double Stack,” “Keep Dry,” “Open This End,” or “Fragile.”

AV Stickers (Approved Vehicle Stickers): Issued by certain ports or terminals, these indicate the container meets local equipment or safety standards for entry or handling.

Inspection Stickers: Applied after a container inspection by customs, quarantine, or transport authorities. They may include the inspection date, agency name, and approval status.

Fumigation Stickers: Show that the container has been fumigated to eliminate pests, especially important for international shipments. These may include the fumigation date, chemical used, and safety warnings.