Table of Contents

Introduction to Shipping Container Parts and Structural Components

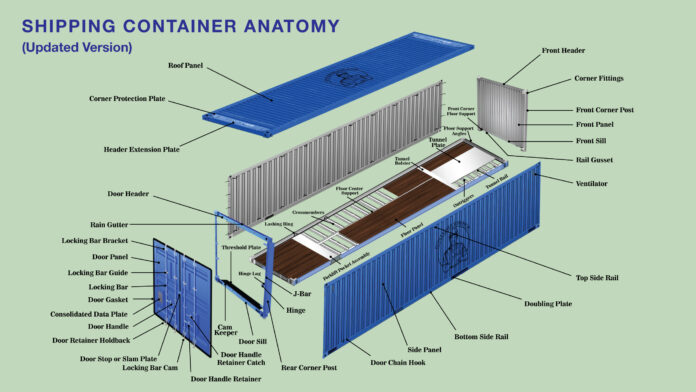

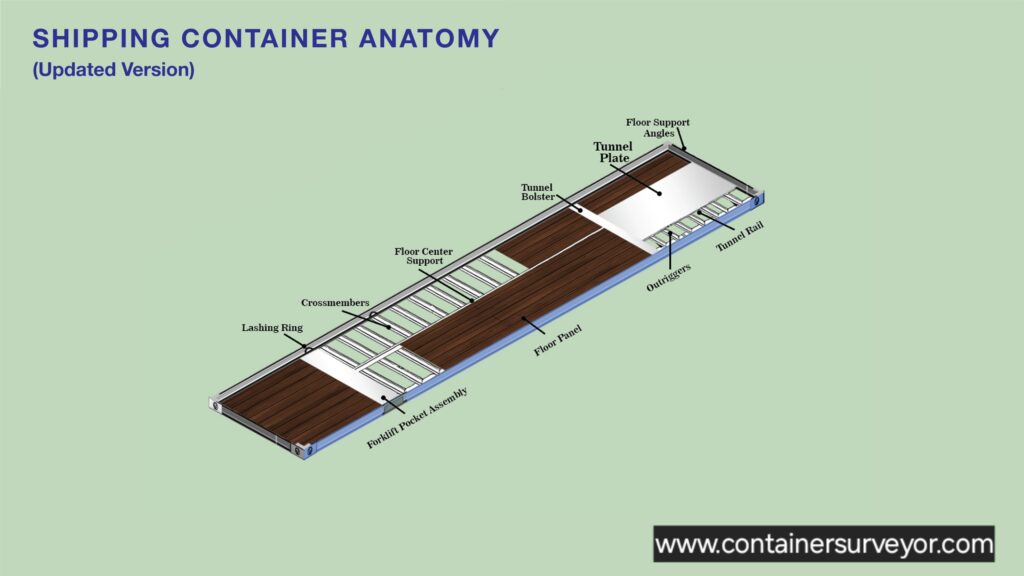

( Anatomy of Shipping Container)

Shipping containers are essential tools for global trade, designed to transport goods efficiently and securely across long distances. To better understand their construction and function, it’s crucial to differentiate between Shipping Container Parts and Shipping Container Structural Components. In this article, we’ll explore 25 key parts and 25 important structural components, breaking them down by the different sections of a container. Whether you’re new to this field or looking to deepen your understanding, this guide is designed to provide clear insights in simple terms.

What are Shipping Container Parts?

Shipping Container Parts refer to the external and internal features that can be replaced or maintained without affecting the overall structure of the container. These parts may include components as below,

| Cam Keeper | Consolidated Data Plate | Corner Rail Gusset | Door Chain Hook | Door Handle | Door Handle Retainer | Door Handle Retainer Catch | Door Hinge |

| Door Retainer Holdback | Door Slam Plate | Doubling Plate | Door Gasket | Hinge Lug | J-Bar | Lashing Rings | Locking Bar |

| Locking Bar Bracket | Locking Bar Cam | Locking Bar Guide | Rail Corner Protector Recess | Rail Gusset | Rain Gutter | Ventilator | Corner Protection Plate |

| Floor Center Support |

What are Shipping Container Structural Components?

Shipping Container Structural Components, on the other hand, refer to the core elements that form the container’s framework. These components, such as the side walls, roof, and corner posts, provide structural integrity and bear the load during transportation. They are critical for maintaining the container’s strength and durability.

| Bottom Rail | Center Support | Corner Casting | Crossmembers | Door Header | Door Panel | Door Sill | Floor board |

| Forklift Pocket | Front Corner Floor Support | Front Corner Post | Front Header | Front Panel | Front Sill | Header Extension Plate | Outriggers |

| Rear Corner post | Roof Panel | Side Panel | Threshold Plate | Top Rail | Tunnel Bolster | Tunnel Plate | Tunnel Rail |

| Tunnel Rail Crossmembers |

Key Differences Between Shipping Container Parts and Components

- Parts are typically smaller, functional elements that can be repaired or replaced without impacting the container’s structure.

- Components form the essential framework, and any damage to these could compromise the container’s overall stability.

For a better understanding, we’ll explore the shipping container by dividing it into seven main sections:

- Front Side (End Side)

- Side of the Container

- Top of the Container

- Door of the Container

- Door Frame (Rear Frame)

- Interior of the Container

- Understructure of the Container

Front Side (End Side) of the container

Front Side of Container – Structural Components

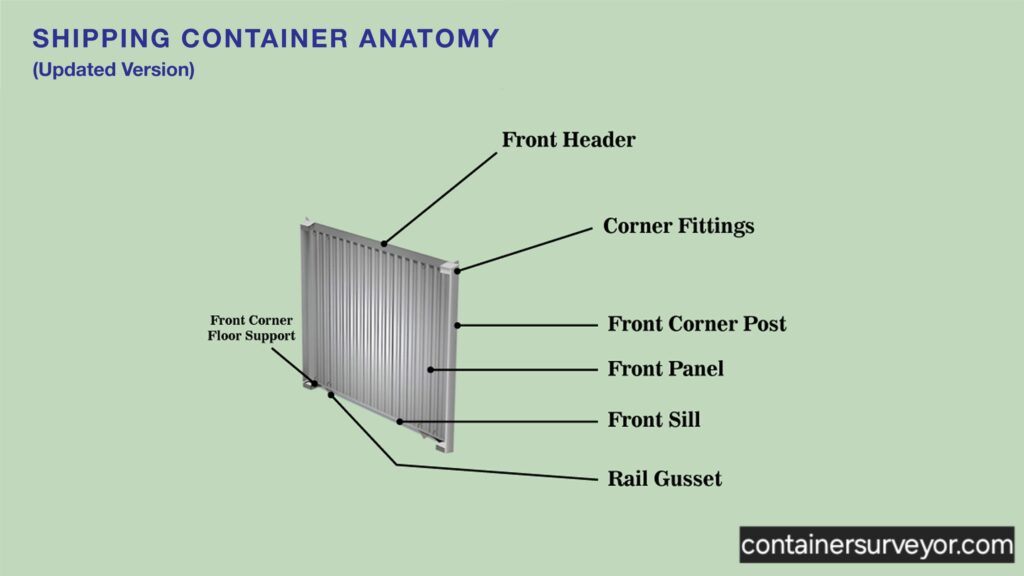

01. Shipping Container Front Header

a) Other names: Container Front Top Rail, Container Header Rail, Front End Top Header

b) Location: Positioned horizontally at the top of the front end of the container, above the front panel.

c) Types or profiles: N/A

d) Description: The shipping container front header provides structural support to the front panel (container end panel) and helps maintain the overall rigidity of the container. It spans the width of the container at the top front edge, connecting the two front corner posts, the front header strengthens the container’s frame, particularly during lifting and stacking operations, ensuring the container remains intact under heavy loads.

02. Shipping Container Corner Fittings

a) Other names: Shipping Container Corner Castings, Shipping Container Corner Blocks

b) Location: Located at all eight corners of the shipping container (four on the top and four on the bottom).

c) Types or profiles: N/A

d) Description: Shipping container corner fittings, also known as corner castings, are structural components found at each of the container’s corners. They serve as crucial connection points for lifting, stacking, and securing the container during transport. Manufactured according to ISO standards, these castings ensure compatibility with cranes, twist locks, and other handling equipment. Reinforced corner fittings are sometimes used for containers designed to carry heavier loads or withstand harsh conditions, ensuring the container remains secure and stable.

03. Shipping Container Front Corner Post

a) Other names: Container Forward Corner Post

b) Location: Positioned at the front corners of the container, vertically connecting the top and bottom rails.

c) Types or profiles: Flat-square and corrugated-square (serpentine) profiles.

d) Description: Shipping container front corner posts are essential for structural stability. Found at the front vertical edges, they provide support by absorbing stress from stacking and lifting. Available in flat-square or corrugated-square (serpentine) profiles, these posts also help maintain alignment when the container is loaded onto trucks or ships. Their robust design ensures that the container remains intact during heavy use, contributing to its long-term durability.

04. Shipping Container Front Panel

a) Other names: Container Front Wall Panel, Container End Wall, Container End Panel, Container Front End Panel

b) Location: Positioned at the front end of the container, forming the front wall between the front header and front sill.

c) Types or profiles: Corrugated steel, flat steel.

d) Description: The shipping container front panel forms the vertical front wall, protecting the cargo from external elements and impacts. Typically made from corrugated steel for added strength, it spans between the front header and front sill. The corrugated profile enhances the container’s structural rigidity, though some containers may feature flat steel panels for specific applications. This component plays a vital role in ensuring the container’s cargo is protected from damage during transport.

05. Shipping Container Front Sill

a) Other names: Container Front Bottom Rail, Container Front Lower Rail

b) Location: Found horizontally at the bottom of the front end of the container, below the front panel.

c) Types or profiles: Box-type profile & C-Type Profile

d) Description: The shipping container front sill supports the front edge of the floor and provides structural reinforcement to the lower section of the front end. It runs between the two front corner posts, forming the base for the front wall. Typically featuring a box-type profile and C-Type profile, the front sill ensures that the container floor is well-supported and can handle the stresses of loading and transport, especially when dealing with heavy cargo.

Front Side of Container – Container Parts

06. Shipping Container Corner Rail Gusset

a) Other names: Container Corner Gusset, Container Reinforcement Gusset

b) Location: Positioned at the front end of the container, connecting the bottom side rail and front corner post. Some designs may include rail gussets on both the top and bottom side rails.

c) Types or profiles: Typically triangular or angled flat steel plates; may vary in size and thickness based on container specifications.

d) Description: The Shipping Container Rail Gusset provides additional structural reinforcement at the junction where the bottom side rail meets the front corner post. It enhances the rigidity and strength of the container’s frame, preventing deformation during lifting, stacking, or handling. Gussets are commonly welded in place to ensure stability and longevity.

Side of the Container

Side of the Container – Structural Container Components

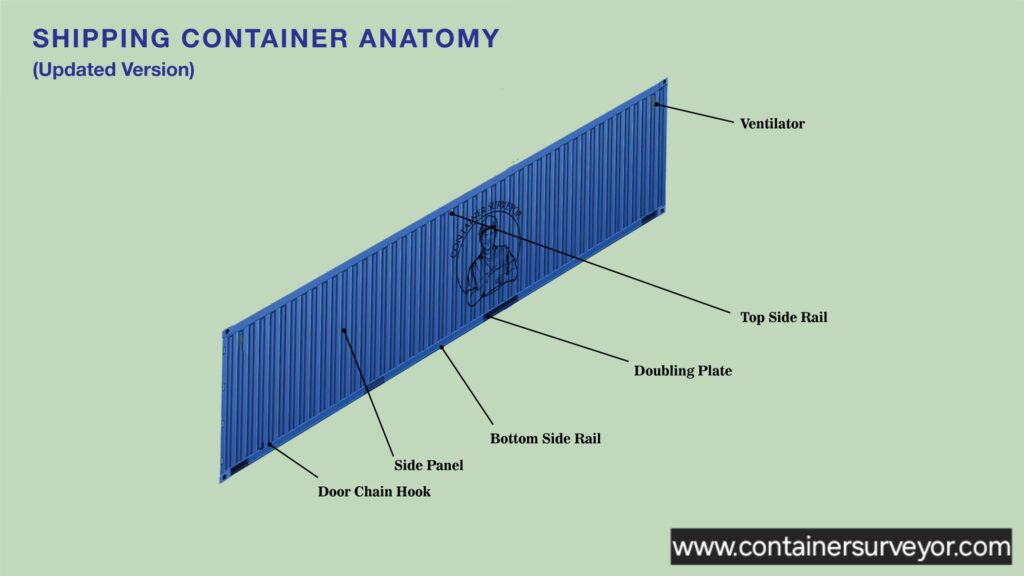

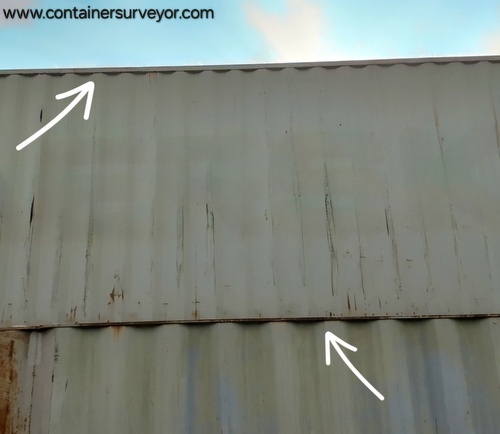

07. Shipping Container Top Side Rail

a) Other names: Container Top Rail, Container Side Top Rail, Container Upper side rail

b) Location: Positioned along the top edges of both side walls, running from corner post to corner post.

c) Types or profiles: Flat-bar and box-type profiles.

d) Description: The shipping container top side rail is a key structural element that supports the roof and contributes to the overall rigidity of the container. Its placement along the top of the side walls helps the container withstand stacking, handling, and harsh conditions. The flat-bar profile is typically found in older containers, while the box-type profile is favored in modern designs for its increased strength and durability.

08. Shipping Container Bottom Side Rail

a) Other names: Container Bottom Rail, Container Side Bottom Rail, Container Lower Side Rail

b) Location: Located at the bottom edge of the container’s side walls, parallel to the top side rail.

c) Types or profiles: C-type profiles & Z-type profiles

d) Description: The shipping container bottom side rail provides critical support to the container’s structure, particularly the floor panels. Running along the bottom edges of the side walls, it plays a vital role in maintaining the container’s form and allowing it to handle heavy loads. C-type & Z-type profiles are available for their strength, ensuring the rail can support the container during lifting and transport.

09. Shipping Container Side Panel

a) Other names: Container Side Wall Panels, Container Side Walls, Container Exterior Walls

b) Location: Positioned on both sides of the container, spanning between the corner posts.

c) Types or profiles: Corrugated steel, flat panel.

d) Description: The shipping container side panel forms the side walls of the container and is typically made of corrugated steel to provide strength and resistance against external pressures. These panels are essential in protecting cargo from weather, impact, and environmental conditions. Corrugated profiles are most common in shipping container components due to their ability to absorb stress, while flat panels are used in specialized containers for certain applications.

Side of the Container – Container Spare Parts

10. Shipping Container Ventilator

a) Other names: Container Air vent, Container Vent Cover, Shipping Container Vents

b) Location: Located near the top of the side panels. In some containers, similar panels are also located on the front and door panels, contributing to the overall structural integrity and protection.

c) Types or profiles: Wide plastic ventilator, Narrow plastic ventilator

d) Description: Shipping container ventilators are designed to allow air circulation inside the container, reducing moisture buildup and preventing condensation. These small openings are placed near the top of the side panels or rear doors. Ventilators come in wide or narrow designs to prevent water entry while allowing airflow, ensuring the cargo inside remains dry and protected, especially during long storage periods.

11. Shipping Container Door Chain Hook

a) Other names: Container Door hook, Container Door Chain Catch

b) Location: Mounted on the top flange of bottom side rail

c) Types or profiles: N/A

d) Description: The shipping container door chain hook is used to secure the container door in an open position, ensuring it remains stable during loading and unloading. Installed on the top flange of bottom side rail.

12. Shipping Container Doubling Plate

a) Other names: Container Reinforcement plate

b) Location: Welded to the web of bottom side rail

c) Types or profiles: Flat steel plate

d) Description: The shipping container doubling plate is used to strengthen or repair weakened areas of the container. Typically welded over on the side bottom rail, it reinforces the container structure and prevents further deterioration. This flat steel plate provides an affordable and effective solution to extend the container’s lifespan, especially in areas prone to heavy wear or stress.

Top of the Container

Top of the Container – Structural Components of Container

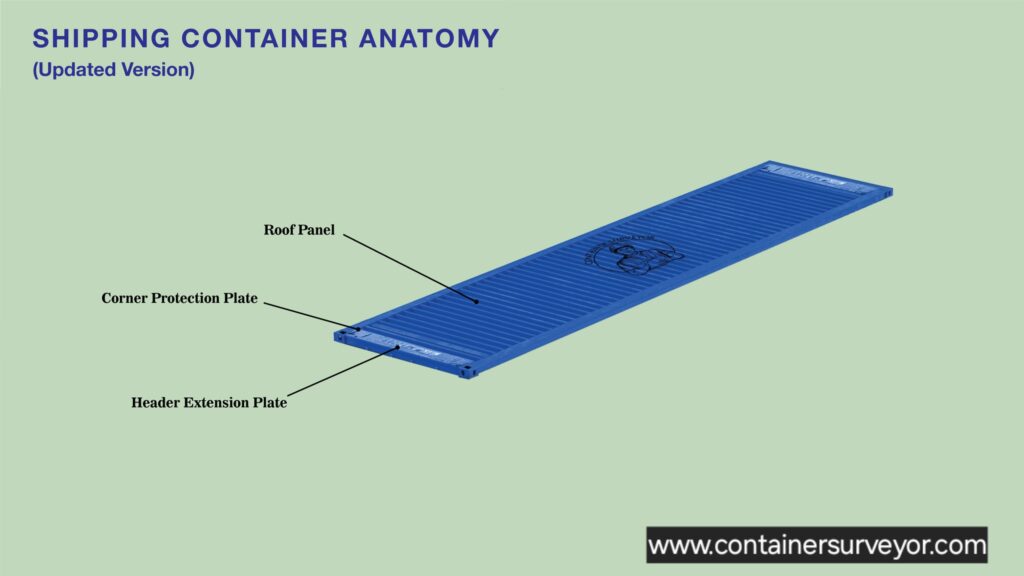

13. Shipping Container Roof Panel

a) Other names: Container Roof sheet.

b) Location: Positioned on the top of the container, forming the roof.

c) Types or profiles: Corrugated steel, Flat steel.

d) Description: The shipping container roof panel forms the top surface of the container, protecting the cargo from weather and external elements. Typically made of corrugated steel, the roof panel provides added strength to withstand stacking and impact. Corrugated profiles are common for increased durability, but flat steel panels may be used in specialized containers.

Top of the Container – Parts of Container

14. Shipping Container Header Extension Plate

a) Other names: Container header reinforcement plate.

b) Location: Located at the top edge of the container, extending from the header to reinforce the upper structure.

c) Types or profiles: Flat steel plate.

d) Description: The shipping container header extension plate is a flat steel plate used to reinforce the header area, providing additional support to the upper section of the container. This plate ensures that the header remains strong and stable, particularly during stacking or when the container is exposed to heavy loads. The extension plate helps distribute pressure more evenly across the container’s top edge, extending the lifespan of the shipping container components in high-stress environments.

15. Shipping Container Corner Protection Plate

a) Other names: Container corner guard, Container corner reinforcement plate.

b) Location: Found at the corners of the container.

c) Types or profiles: Flat steel plate.

d) Description: The shipping container corner protection plate is designed to reinforce and protect the container’s corners, which are subject to heavy stress during lifting, stacking, and transportation. These flat steel plates are welded over vulnerable corner areas to prevent damage from impacts or rough handling. By reinforcing the corners, these plates ensure that the container maintains its structural integrity, preventing costly repairs and extending the container’s service life.

Door Frame (Rear Frame)

Door Frame (Rear Frame) – Structural Container Components

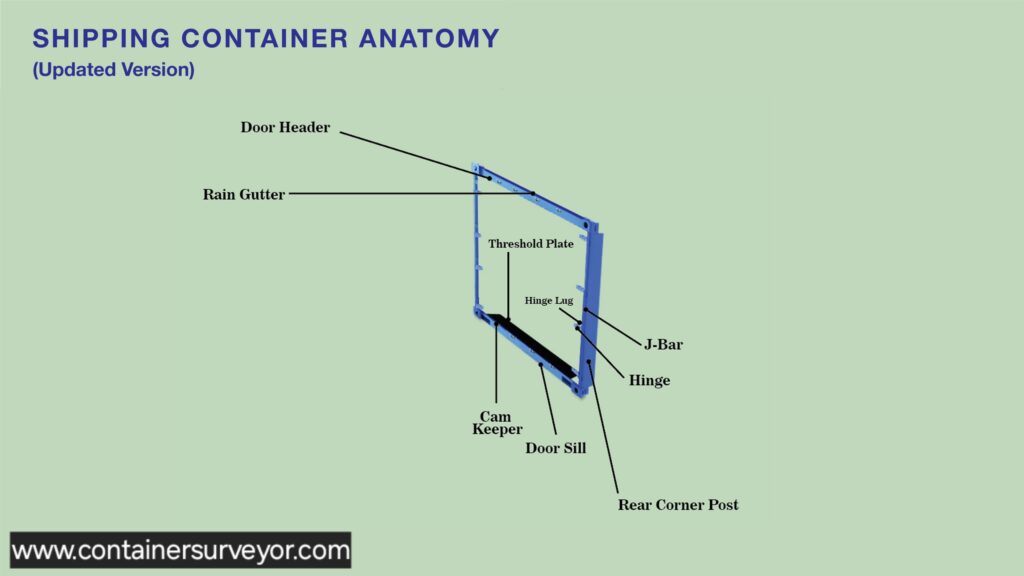

16. Shipping Container Door Header

a) Other names: Shipping Container Rear Header, Shipping Container Door Top Rail

b) Location: Positioned horizontally above the container’s rear doors.

c) Types or profiles: Box-type profile

d) Description: The shipping container door header is a structural component located above the rear doors, providing stability and strength to the door frame. It connects the two rear corner posts, supporting the doors and ensuring they remain aligned during opening and closing. Available in box-type or flat-bar profiles, the door header plays a key role in maintaining the structural integrity of the container while providing clearance for cargo to be loaded and unloaded through the doors.

17. Shipping Container Door Sill

a) Other names: Shipping Container Rear sill, Shipping Container Bottom Door Rail

b) Location: Positioned horizontally at the bottom of the rear door frame.

c) Types or profiles: Box-type profile, Open Type Profile

d) Description: The shipping container door sill,

also known as the rear sill, is located at the base of the container’s rear doors. It provides structural support and forms the threshold for loading and unloading cargo. This component reinforces the lower door frame, ensuring that the doors remain stable during frequent use. The door sill is available in box-type or flat steel plate profiles, playing a vital role in maintaining the container’s integrity while withstanding wear and tear.

18. Shipping Container Rear Corner Post

a) Other names: Shipping Container Door Corner post

b) Location: Positioned vertically at the rear corners of the container, supporting the door frame.

c) Types or profiles: n/a

d) Description: The shipping container rear corner post is a vertical support structure located at the back of the container, forming part of the door frame. It provides stability for the rear end of the container and helps distribute the load during lifting and stacking.

19. Shipping Container Threshold Plate

a) Other names: Shipping Container Door threshold, Shipping Container sill plate

b) Location: Positioned at the bottom of the container door frame, at the rear end.

c) Types or profiles: Flat steel plate.

d) Description: The shipping container threshold plate is installed at the base of the rear door opening, providing a smooth surface for loading and protecting the floor. This flat steel plate reinforces the door frame, ensuring stability and preventing damage to the container floor during frequent loading and unloading. It also serves as a barrier to keep water and debris out of the container, preserving the cargo inside.

Door Frame (Rear Frame) – Container spare Parts

20. Shipping Container J-Bar

a) Other names: N/A

b) Location: Mounted vertically on the container doors, controlling door locking mechanisms.

c) Types or profiles: N/A

d) Description: The shipping container J-bar is a vertical locking bar attached to the container doors, used to secure them during transport. When turned, it engages the cams and cam keepers to lock the doors tightly. The J-bar is designed for easy operation and ensures that the container doors remain secure, even under harsh transport conditions. Available in fixed or adjustable profiles, the J-bar is essential for maintaining the safety of the cargo by preventing unauthorized access.

21. Shipping Container Rain Gutter

a) Other names: Container Drip rail

b) Location: Found above the container doors or along the roof edge.

c) Types or profiles: flat profile.

d) Description: The shipping container rain gutter helps divert water away from the door openings and prevents it from entering the container during rainy conditions. Typically installed above the rear doors. By keeping moisture out, the rain gutter helps protect the cargo from water damage, ensuring the container remains weatherproof.

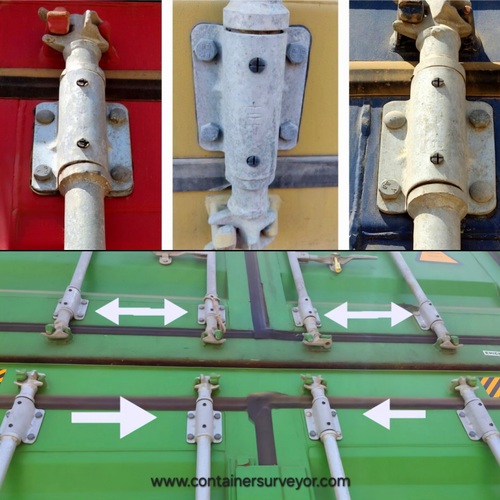

22. Shipping Container Cam Keeper

a) Other names: Shipping Container Locking retainer, Shipping Container door cam lock

b) Location: Positioned on the container door frame, engaging with the cam to secure the door.

c) Types or profiles: N/A

d) Description: The shipping container cam keeper is an essential component of the door locking mechanism, holding the door cams in place when the container doors are closed. Located on the door frame, it engages with the cam bar to provide a tight seal and secure the doors. The cam keeper ensures that the container remains locked and sealed during transport, preventing unauthorized access and protecting the cargo.

23. Shipping Container Hinge

a) Other names: Shipping Container Door hinge

b) Location: Positioned on the side of the container doors, connecting the doors to the frame.

c) Types or profiles: N/A

d) Description: The shipping container hinge allows the container doors to pivot open and closed. Typically made from steel, the hinges are welded to the door frame and door, providing a sturdy and durable connection. Shipping container hinges are built to withstand heavy use, ensuring that the doors operate smoothly even in harsh environmental conditions.

24. Shipping Container Hinge Lug

a) Other names: N/A

b) Location: Attached to the container’s J-Bar

c) Types or profiles: N/A

d) Description: The shipping container hinge lug is a small, sturdy component that connects the container door to the door frame, allowing it to pivot open and closed. These lugs are welded to the J-bar, providing a secure mounting point for the door hinges. Hinge lugs are available in fixed or removable profiles, offering flexibility for door removal or replacement. This component is critical for smooth door operation and maintaining alignment over time.

25. Shipping Container Rail Corner Protector Recess

a) Other names: Container Corner protector groove, Container rail protector slot

b) Location: Found at under the front sill.

c) Types or profiles: Recessed groove.

d) Description: The shipping container rail corner protector recess is a small, recessed area designed to protect the container’s rails from damage during handling or stacking. Located at under the front sill corners.

Door of the Container

Door of the Container – Structural Components

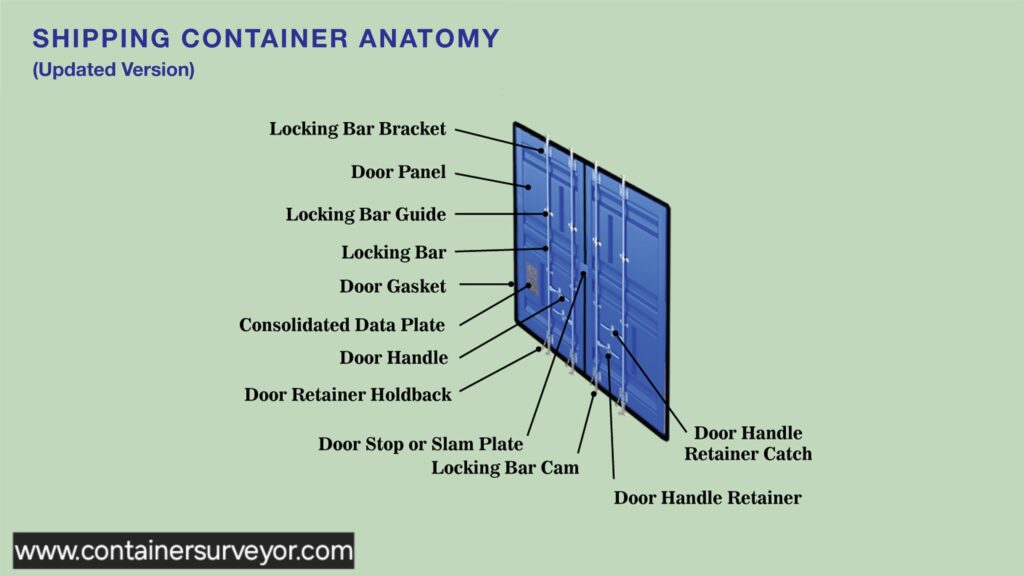

26. Shipping Container Door Panel

a) Other names: Shipping Container Door Wall

b) Location: Forms the outer surface of the container’s doors.

c) Types or profiles: Corrugated steel panel, flat steel panel.

d) Description: The shipping container door panel is the large, flat surface that makes up the majority of the container door. Typically made from corrugated or flat steel, it provides structural integrity to the door and protects the cargo inside. Corrugated panels offer additional strength and durability, while flat panels are used for specialized containers. The door panel is an essential component of the container’s weatherproof and secure design.

Door of the Container – Container Parts

27. Shipping Container Locking Bar Bracket

a) Other names: Shipping Container Locking bar mount, Shipping Container locking bar support, Shipping Container Outer Large Bearing bracket

b) Location: Mounted on the container door and door frame to hold the locking bar in place.

c) Types or profiles: N/A

d) Description: The shipping container locking bar bracket is a key component that secures the locking bar to the container door. This bracket allows the locking bar to rotate and engage with the cams, securing the container doors. Brackets are available in fixed or adjustable profiles and are essential for maintaining the door’s locking system. By supporting the locking bar, the bracket ensures the security of the container during transport.

28. Shipping Container Locking Bar

a) Other names: Shipping Container Door locking bar, Shipping Container Vertical locking bar, Shipping Container Locking Rod, Shipping container Locking Gear, Shipping Container Door Locking System Bar

b) Location: Installed vertically on the container doors, engaging with cams and cam keepers.

c) Types or profiles: N/A

d) Description: The shipping container locking bar is a robust, vertical bar that secures the container doors by engaging with the cam mechanism. When turned, the bar locks the door into place, preventing it from opening during transit. Containers may have a single or double locking bar system for enhanced security. The locking bar is vital in ensuring the container doors stay sealed, protecting the cargo from theft or environmental exposure.

29. Shipping Container Locking Bar Guide

a) Other names: Shipping Container Locking bar keeper, Shipping Container Bearing Bracket Outer Small, Shipping Container Locking Bar Bracket Small, Shipping Container Locking Bar Bracket Small

b) Location: Positioned along the container door to guide the locking bar during opening and closing.

c) Types or profiles: N/A

d) Description: The shipping container locking bar guide is a small bracket that ensures the locking bar remains aligned as it rotates to lock or unlock the container door. The guide holds the bar in place, preventing it from moving laterally or becoming misaligned. This component is critical for smooth and secure door operation, preventing damage to the locking system during repeated use.

30. Shipping Container Locking Bar Cam

a) Other names: Shipping Container Door Cam / Shipping Container Security Cam

b) Location: Mounted on the container’s locking bar.

c) Types or profiles: N/A

d) Description: The shipping container locking bar cam is a critical part of the door locking system. This component attaches to the locking rod and rotates to engage the locking bar, securing the door. The cam is designed to lock tightly when the bar is turned, preventing unauthorized entry. The cam is essential for ensuring the container doors remain locked and sealed during transportation.

31. Shipping Container Door Stop or Slam Plate

a) Other names: Shipping Container Door stopper

b) Location: Positioned near the bottom of the container door frame.

c) Types or profiles: N/A

d) Description: The shipping container door stopper is a small yet essential component designed to hold the container door in a fully open position. Typically located on the bottom side rail or corner post, it prevents the door from swinging closed during loading or unloading operations. This ensures safety and convenience, especially in windy conditions or uneven terrain.

32. Shipping Container Consolidated Data Plate

a) Other names: Shipping Container CSC Plate, Shipping Container Certification Plate

b) Location: Affixed to the outside of the container, usually near the doors.

c) Types or profiles: Metal plate, engraved plate.

d) Description: The shipping container consolidated data plate provides essential information about the container, including its compliance with the Convention for Safe Containers (CSC) standards. This plate includes details like the manufacturer, weight limits, and inspection history. It is a crucial component for regulatory and safety purposes, ensuring that the container is fit for international transport. The data plate is made from durable metal and is typically engraved for longevity.

33. Shipping Container Door Handle

a) Other names: Shipping Container Door Lever, Shipping Container Locking Handle

b) Location: Attached to the locking bar on the container doors.

c) Types or profiles: Forging Type & Pressing Type

d) Description: The shipping container door handle is used to operate the locking system of the container doors. When turned, it rotates the locking bar, allowing the doors to open or close. Handles are typically Forging Type & Pressing Type for better grip and leverage. This component ensures that the doors can be securely locked and easily opened, contributing to the overall security and functionality of the container during transport.

34. Shipping Container Door Handle Retainer

a) Other names: Shipping Container Door Handle Catch, Shipping Container Door Handle Retainer Catch

b) Location: Mounted on the container door near the handle.

c) Types or profiles: Forging Type Handle Retainer & Press Type Handle Retainer

d) Description: The shipping container door handle retainer secures the door handle in place, preventing it from rotating unintentionally during transit. This component latches the handle after it has been turned to the locked position, ensuring that the locking bar remains engaged. Available in Forging Type Handle Retainer & Press Type Handle Retainer, the retainer is crucial for maintaining the security of the container’s doors, preventing accidental openings.

35. Shipping Container Door Handle Retainer Catch.

a) Other names: Shipping Container Door Handle Custom Catch, Shipping Container Door Locking Device Retainer Catch

b) Location: Positioned near the door handle on the exterior of the container door.

c) Types or profiles: Forging Type & Press Type

d) Description: The shipping container door handle retainer catch, also known as a door handle latch or clip, is a small mechanism that holds the container door handle securely in place when the door is closed or open. This catch ensures the handle remains locked in position, preventing it from swinging or moving during transportation. Available in Forging Type & Press Type, the door handle retainer catch is crucial for maintaining the security of the container doors, especially when subjected to movement and vibration during shipping.

36. Shipping Container Door Retainer Holdback

a) Other names: Shipping Container Door holdback

b) Location: Installed on the container’s Locking Bar

c) Types or profiles: Hook-type holdback, latch-type holdback.

d) Description: The shipping container door retainer holdback is used to keep the container doors open during loading and unloading. This component ensures that the doors do not swing closed unexpectedly, providing convenience and safety when accessing the container. This component is essential for efficient cargo handling and door management.

37. Shipping Container Door Gasket

a) Other names: Door seal, weather seal

b) Location: Fitted around the edges of the container doors.

c) Types or profiles: N/A

d) Description: The shipping container door gasket is a weatherproof seal that fits around the edges of the doors to prevent water, dust, and other elements from entering the container. Made from rubber or foam, these gaskets ensure a tight seal when the doors are closed, protecting the cargo inside from environmental damage. The door gasket is vital for maintaining the integrity of the container’s interior, especially during ocean transport or long storage periods.

Interior of the Container

Interior of the Container – Structural Components

38. Shipping Container Floor Panel

a) Other names: Shipping Container Floorboard, Shipping Container Plywood

b) Location: Positioned at the base of the container, forming the interior floor.

c) Types or profiles: Hardwood plywood, bamboo, steel etc.

d) Description: The shipping container floor panel is crucial for supporting cargo inside the container. Made primarily from hardwood plywood or bamboo, these panels are engineered to handle heavy loads and resist moisture. Steel floor panels are sometimes used in specialized containers for added durability. The floor panels are fitted securely to the bottom side rails and cross members, ensuring the container can support both light and heavy cargo during transport.

39. Shipping Container Tunnel Plate

a) Other names: Shipping Container Gooseneck tunnel plate

b) Location: Positioned at the bottom of the container, covering the gooseneck tunnel area in 40ft containers.

c) Types or profiles: Flat steel plate.

d) Description: The shipping container tunnel plate is a flat steel panel that covers the gooseneck tunnel, providing a smooth surface for loading and preventing damage to the floor. Located at the bottom center of some containers, it reinforces the floor structure and ensures the tunnel area remains intact. This plate is vital in 40ft containers used on gooseneck chassis, as it allows for safer, more stable stacking during transport.

40. Shipping Container Tunnel Bolster

a) Other names: Shipping Container Tunnel beam, Shipping Container tunnel support

b) Location: Located beneath the floor at the gooseneck tunnel area in 40ft containers.

c) Types or profiles: I-beam, box-type beam.

d) Description: The shipping container tunnel bolster is a structural support beam used in containers with gooseneck tunnels. It reinforces the floor and strengthens the container’s bottom, allowing it to handle the additional stress of being transported on gooseneck chassis. Available in I-beam or box-type profiles, the tunnel bolster distributes weight evenly across the container’s floor, ensuring safe transport of heavy cargo and protecting the tunnel area from damage.

41. Shipping Container Floor Center Support

a) Other names: N/A

b) Location: Positioned underneath and top the floor panels, running laterally across the container’s base.

c) Types or profiles: Hat-Section, Flat-Bar Profile

d) Description: The shipping container floor center support is a key structural component that reinforces the floor, ensuring it can handle heavy loads. These supports run laterally beneath and top the floor panels. This component is essential for maintaining the structural integrity of the container’s floor during loading, unloading, and transport.

42. Shipping Container Front Corner Floor Support

a) Other names: N/A

b) Location: Found at the front corners of the container, underneath the floor near the corner posts.

c) Types or profiles: N/A

d) Description: The shipping container front corner floor support is a reinforcement component located at the front corners of the container’s base. It provides additional strength to the floor near the corner posts, an area that experiences high stress during transport and handling. This support prevents floor damage and ensures the container remains structurally sound when subjected to heavy loads, extending the service life of the container.

Interior of the Container – Container Parts

43. Shipping Container Lashing Rings

a) Other names: Lashing fittings / Lashing Bars / Lashing Rods

b) Location: Installed along the interior of top side rail, bottom side rail, or corner posts inside the container.

c) Types or profiles: N/A

d) Description: Shipping container lashing rings are used to secure cargo during transport, preventing movement that could cause damage. These rings provide anchor points for ropes, chains, or straps to tie down cargo. Lashing rings are welded to the container’s interior at multiple points, ensuring strong attachment. The swivel ring type allows greater flexibility in securing cargo at various angles, while the welded ring offers rigid stability for heavy-duty loads.

Understructure of the Container

Understructure of the Container – Structural Container Components

44. Shipping Container Crossmembers

a) Other names: N/A

b) Location: Located beneath the container floor, running perpendicular to the side rails.

c) Types or profiles: N/A

d) Description: Shipping container crossmembers are structural beams that support the container floor, running horizontally between the side rails. They distribute the load of the cargo across the container’s structure, ensuring that the floor remains stable during transportation and loading, and providing essential strength to the container’s chassis. These components play a critical role in maintaining the integrity and durability of the container’s flooring.

45. Shipping Container Outriggers

a) Other names: N/A

b) Location: Positioned on the outer edges of the container’s underside, connecting to the side rails.

c) Types or profiles: N/A

d) Description: Shipping container outriggers are horizontal supports located on the outer edges of the container’s underside, providing additional stability and strength to the container’s structure. They connect to the side rails and help distribute the weight of the cargo, especially when the container is lifted or transported, and offering flexibility depending on the container’s design. These components are crucial for maintaining balance and support during handling.

46. Shipping Container Tunnel Crossmembers

a) Other names: N/A

b) Location: Positioned under the container’s tunnel section, running perpendicular to the tunnel rails.

c) Types or profiles: N/A

d) Description: Shipping container tunnel crossmembers are specialized floor beams located beneath the tunnel section of a container, providing structural support to the tunnel area. These crossmembers ensure that the tunnel, a recessed area for gooseneck trailers, maintains its strength and stability during transport, ensuring that the container floor in the tunnel section remains strong under heavy loads.

47. Shipping Container Tunnel Rail

a) Other names: N/A

b) Location: Found along the sides of the container’s tunnel, supporting the tunnel section.

c) Types or profiles: N/A

d) Description: The shipping container tunnel rail is a structural beam located along the sides of the tunnel area, providing support and stability to the tunnel section. These rails help maintain the container’s strength, especially when it is loaded onto gooseneck trailers, where the tunnel recess is utilized, and offering various levels of strength depending on the container’s design. They ensure the container’s overall structural integrity during transport.

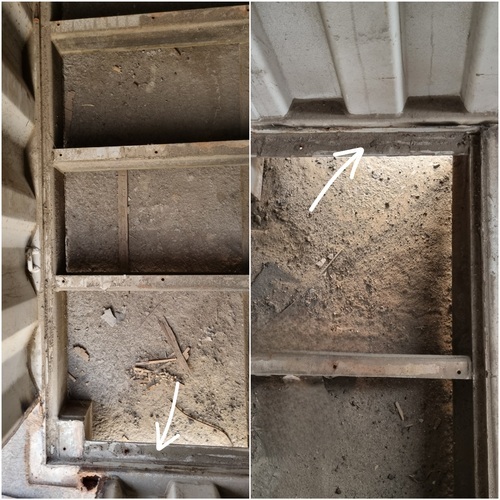

48. Shipping Container Forklift Pocket Assembly

a) Other names: N/A

b) Location: Installed along the bottom of the container, on both sides, for forklift handling.

c) Types or profiles: N/A

d) Description: The shipping container forklift pocket assembly consists of two reinforced pockets on the underside of the container, allowing forklifts to lift and move the container. These pockets are designed to accommodate the tines of a forklift, providing a secure and balanced lift. This component is crucial for handling containers in warehouses or ports without the need for cranes.

49. Shipping Container Rail Gusset

a) Other names: N/A

b) Location: Found at the joints between the crossmembers and side rails.

c) Types or profiles: N/A

d) Description: The shipping container rail gusset is a triangular or rectangular metal plate

used to reinforce the joints between structural components, such as the crossmembers and side rails. Gussets strengthen these connections, ensuring that the container can withstand heavy loads and stress during transport, gussets are essential for maintaining the overall structural integrity of the container, preventing deformation or failure at key stress points.

50. Shipping Container Floor Support Angles

a) Other names: Shipping Container Floor Reinforcement Angles

b) Location: Positioned underneath the container floor, connecting to the crossmembers and side rails.

c) Types or profiles: N/A

d) Description: Shipping container floor support angles are metal brackets that reinforce the connection between the container floor, crossmembers, and side rails. These angles provide additional support to the floor, ensuring it can withstand heavy loads without sagging or bending, and play a critical role in maintaining the container’s structural integrity, especially during heavy loading and transport.