Table of Contents

Shipping containers travel across the globe, facing various conditions that can lead to damage at any point in their journey. One common issue is container floor damage, which can occur anytime and anywhere. Some examples are detailed in our floorboard damage examples article, but popular types of floor damage include container floor delamination, rolling shear failure, and container floor broken. When these types of damage occur, it’s crucial to replace the affected floor to ensure the cargo’s safety during operations. Proper repair and maintenance are essential to maintain the structural integrity of shipping containers.

Shipping Container Floor Delamination

Container Floor Delamination refers to the separation of layers (or plies) within plywood due to the failure of the adhesive in the glue lines between the laminates.

What Causes Delamination in Shipping Container Floors?

- Poor-quality glue.

- Accumulated travel and impacts from forklifts.

- Forklift wheel overloading (when weight exceeds the floor’s capacity).

- Natural aging of the wood (weakens the glue bonds over time).

- Moisture ingress into the plywood (e.g., from excessive steam cleaning).

What is Surface Delamination? How it happens?

Surface delamination is a condition where the layers of a floor panel start to separate or peel away from each other. This typically occurs when the glue bonding the layers together fails, causing the layers to lose adhesion.

One common cause of surface delamination is improper gluing during the manufacturing process. If the glue is not applied correctly or uniformly, it may not properly bond the wood layers. A telltale sign of this issue is the appearance of a brown glue layer that lacks embedded wood fibers, indicating that the glue didn’t penetrate the wood as it should have. As a result, the layers can start to pull apart, leading to delamination and weakening the floor’s structural integrity.

Container Rolling Shear Failure

Rolling Shear Failure of the floorboard occurs when the wood fibers within the plywood laminates themselves, rather than the adhesive, fail due to a load that exceeds the natural strength of the wood. This type of failure is characterized by separation patterns in the transverse plies, starting at or near the center of the innermost transverse layers.

What Causes Rolling Shear Failure in Shipping Container Floors?

- Accumulated travel by forklifts.

- Impacts.

- Forklift wheel overloading.

- Moisture ingress into the plywood (e.g., from excessive steam cleaning).

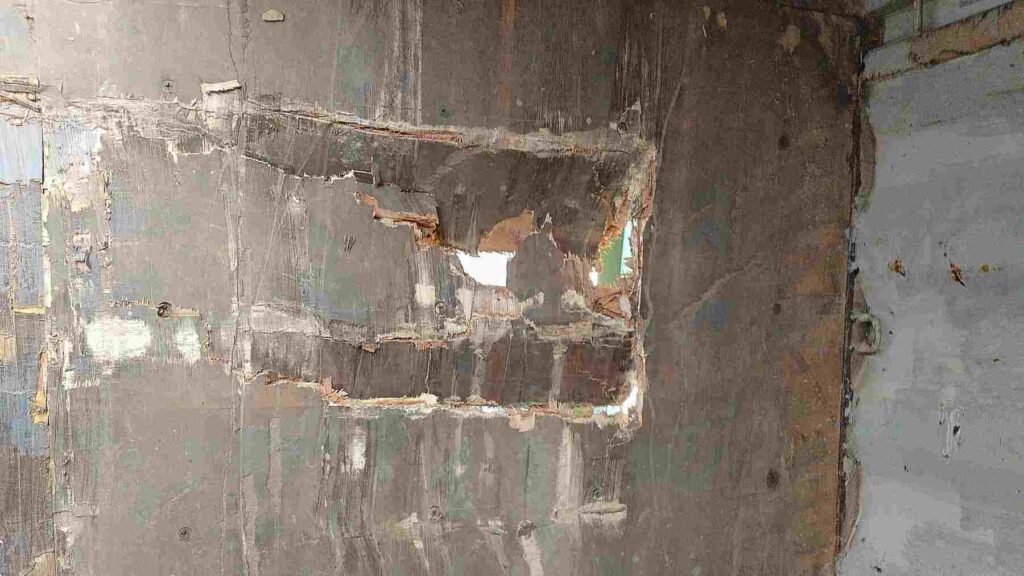

Shipping Container Floor Broken

Container floor broken (breakage) refers to the separation or fracture of plywood flooring in any direction, affecting one or more layers of the laminates. It includes the disruption of either the top or bottom surface veneer, compromising the structural integrity of the flooring.

The surface veneer is the outermost layer of laminate or the outer three-ply pack of laminates, located on either the top or bottom surface of the plywood.

What Causes floor broken in Shipping Container Floors?

- Results from impact or overloading.

- Occurs when the force applied surpasses the floor’s structural capacity, causing cracks or splits.

- Finger Cracking : A specific type of breakage where cracks form between the fingers or joints of the plywood, typically due to impacts or excessive weight bearing down on the flooring.

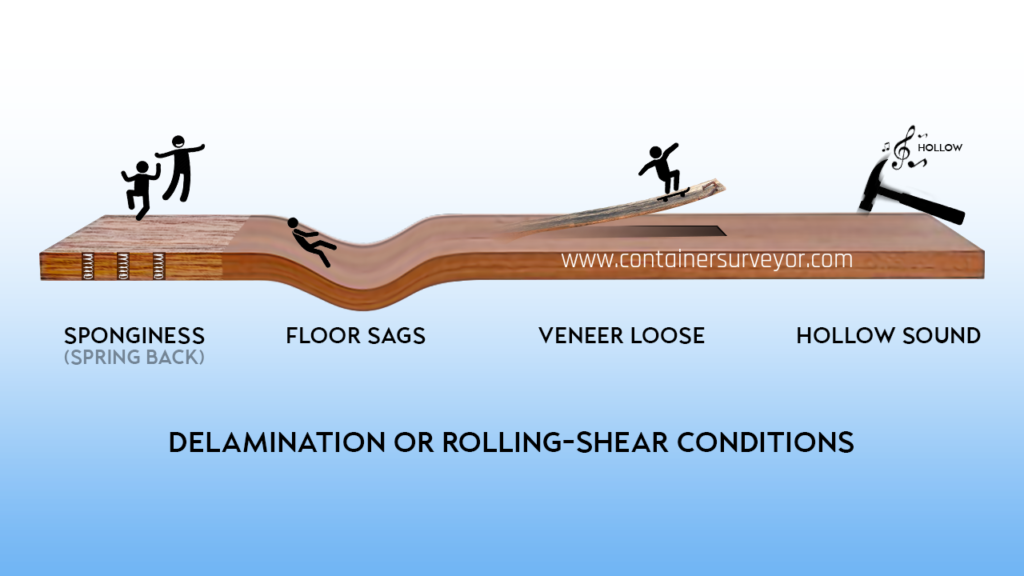

Indicators of Container Floor Delamination or Rolling Shear Failure

One or more of the following conditions may indicate delamination and/or rolling shear failure.

- The floor feels spongy or has a “spring back” effect, where it yields underfoot and returns to its original position once the foot is lifted.

- The top veneer of the floor is loose and sticks out above the floor screws.

- The floor visibly sags between crossmembers when it is either unloaded or carrying normal operating loads.

- Tapping the floor with a hammer between crossmembers produces a “hollow” sound, unlike the typical “solid” sound of an intact floor.

Shipping Container Finger Cracking

According to IICL TB 003, 1 May 2005, titled “Finger Cracking in Plywood Floor Boards,” a finger crack is a type of separation in the surface veneer of plywood. It is characterized by a transverse (crosswise) crack with longitudinal (lengthwise) separations at both ends of the transverse crack. Not all instances of finger cracking require repair; it is considered repair-worthy only if accompanied by one or more of the following conditions:

- A visible sign of impact on the opposite side.

- Damage to adjacent components such as crossmembers, sills, floor rails, or hat sections.

- Visible bowing of the opposite side of the floor.

- A hollow sound when hammer tested, indicating a lack of solidity in the material.

Classification of incidents: Wear vs Damage

Damage incidents

Any of the following Combinations are considered damage.

- Soft or spongy floorboards, noticeable sagging between crossmembers, and a hollow sound when tapped can signal underlying issues. These issues may include impact damage, such as dents or gouges, or signs of overloading, like crossmembers that are permanently bowed. Additionally, cracks or more severe breaks in the outer veneer indicate that the floorboards have been compromised.

A. Floorboard Sponginess

What It Is – Sponginess in a floorboard refers to a soft or bouncy feeling when pressure is applied. This is often a sign that the material inside the panel has deteriorated, possibly due to moisture absorption or internal decay.

Why It Matters – A spongy floorboard has lost much of its strength and rigidity, making it susceptible to further damage. Over time, this could lead to complete failure, especially when under load, posing safety risks.

B. Sags floorboards between Crossmembers

What It Is – Sagging occurs when the floorboard appears to bow between the supporting crossmembers. This usually indicates that the floorboard’s ability to bear weight evenly has been compromised.

Why It Matters – Sagging weakens the entire structure, causing uneven load distribution. This not only accelerates the degradation of the floorboard but also puts additional strain on the supporting framework, leading to potential structural failures.

C. Hollow Sounding Hammer Taps

What It Is – When a floorboard is tapped with a hammer and produces a hollow sound, it often means that the internal structure is compromised. This hollowness could be due to material separation, decay, or voids within the panel.

Why It Matters – A hollow-sounding floorboard is a strong indication that it no longer has the internal integrity needed to support loads effectively. This could result in sudden and unexpected failures, making it a critical issue to address.

D. Impact Indicators (Dents or Gouges)

What It Is – Dents or gouges on a floorboard’s surface indicate that it has suffered physical damage, likely from an impact. These could range from minor surface blemishes to deep

indentations that affect the panel’s structure.

Why It Matters – Even small dents and gouges can weaken a floorboard, making it more prone to cracks and further damage. Over time, these seemingly minor issues can escalate, leading to more severe structural problems

E. Overloading Signs (Permanently Bowed Crossmembers)

What It Is – If crossmembers—the horizontal supports beneath the floorboards are permanently bowed, this is a sign that the panel has been overloaded. The excessive weight has caused the supports to deform, reducing their effectiveness.

Why It Matters – Permanently bowed crossmembers are a serious concern as they indicate that the panel has been subjected to stress beyond its designed capacity. This not only weakens the panel itself but also jeopardizes the stability of the entire structure it supports.

F. Breakage of Outer Veneer (Finger Cracks or Severe Breaks)

What It Is – Breakage in the outer veneer, such as finger cracks or more severe fractures, indicates significant damage to the floorboard’s surface. These cracks may extend into deeper layers, compromising the floorboard’s overall strength.

Why It Matters – Cracks and breaks in the veneer are critical indicators of damage that can quickly worsen if not repaired. Such breakage exposes the inner layers to environmental factors, accelerating deterioration and increasing the risk of total structural failure.

- Cracking or breaking of the outer veneer with no signs of delamination, rolling-shear failure, impact, or overloading.

- Cracking or breaking of the outer veneer with no delamination or rolling-shear failure, but with visible signs of impact or overloading.

Wear incidents

Any of the following Combinations are considered wear.

- Delamination Without Impact, Overloading, or Veneer Breakage

Delamination occurs on its own, with no signs of impact (such as dents), overloading (exceeding weight capacity), or any breakage of the outer veneer. This situation is considered normal wear and tear.

- Delamination With Veneer Breakage but No Impact or Overloading

The floor shows delamination along with some breakage of the outer veneer, but there are no signs of impact or overloading. This combination, despite the veneer breakage, is still classified as wear because no external forces are responsible.

- Delamination With Impact or Overloading but No Veneer Breakage

Delamination occurs alongside signs of impact or overloading, but without any breakage of the outer veneer. Even though external forces are present, the intact veneer suggests that the condition is still wear rather than damage.

What is container floor decay ?

Container floor decay refers to the gradual deterioration of the wooden floorboards within a shipping container, primarily caused by fungal attacks. When wood is exposed to moisture over prolonged periods, it creates an environment conducive to fungal growth. This leads to the breakdown of the wood’s structure, resulting in decay.

Typical signs of decayed wood include,

- Splitting Across the Grain: The wood may develop cracks or splits running across the grain, significantly weakening its structural integrity.

- Soft and Punky Texture: Decayed wood often feels soft or spongy to the touch, a condition commonly referred to as “punky.” This texture is a clear indicator that the wood fibers have been compromised.

- Stringy or Crumbly Appearance: As decay advances, the wood may appear stringy or crumbly, easily breaking apart due to the degradation of cellulose and lignin.

The presence of wood decay can result in substantial reductions in the strength of the container floor, making it less capable of supporting loads and more prone to further damage. Recognizing these signs early is crucial for maintaining the structural integrity of the container and preventing further deterioration.

What is High impact over small area?

When a heavy impact occurs over a small area of the container floor, it can lead to a different type of failure. This can result in simultaneous rolling shear failures across multiple plies throughout the thickness of the floor. Additionally, it may cause a bending failure in the outermost longitudinal plies.