Table of Contents

Shipping containers are the backbone of global trade, transporting goods across the world. However, their floors can take quite a beating, leading to container floor damage. Understanding what causes this damage is key to keeping containers in top condition. From environmental exposure and heavy loads to rough handling, various factors contribute to the wear and tear of these floors. Issues like chemical spills, pest infestations, and uneven surfaces in container yards can also cause significant damage. Regular maintenance and inspections are crucial to prevent these problems from becoming costly headaches. Let’s dive into the common causes of container floor damage.

Environmental Factors

Moisture and Water Damage : Containers often spend time in empty container yards where they can be exposed to rain and humidity. This exposure can lead to moisture seeping into the wood, causing rot and decay. Additionally, floods in container yards can severely damage the floors, as prolonged contact with water weakens the wood and leads to container floor damage. Proper protection and drainage systems are essential to prevent this type of damage.

Load & Offload Related Issues

- Heavy Loads: Some shippers overlook weight panels and overload containers, which can stress the floorboards and lead to container floor damage. Additionally, forklifts traveling over weak or compromised floors can further exacerbate this damage, compromising the integrity of the container.

- Physical Impact: Rough handling during loading and unloading can damage the floorboards. Containers can also be struck underneath, especially if handled carelessly. Moreover, poor conditions of empty truck trailers, such as upward inclines, can lead to improper loading onto trailers, resulting in floor damage.

- Uneven Floor Conditions: When containers are placed on uneven ground in container yards, the floorboards can warp or bend. This uneven support can lead to container floor damage over time, as the stress is not evenly distributed across the floor.

Biological Factors

Pest Infestation : Termites and other pests are attracted to wood and can cause significant harm if they infest your container. Their activity can weaken the floorboards, leading to structural damage and contributing to container floor damage.

Chemical Factors

Chemical Spills : Containers often carry chemicals, and any spills can severely damage the floorboards. These substances can weaken the wood, leading to significant container floor damage if not addressed promptly.

Wear and Tear

Age and Wear : Over time, containers naturally experience wear and tear. As they are used repeatedly, the floorboards show signs of aging, eventually needing maintenance or replacement to prevent container floor damage.

Maintenance

Poor Maintenance : Skipping regular inspections and maintenance can allow minor issues to develop into significant problems. Regular check-ups are crucial to keeping the floorboards in good condition and preventing container floor damage.

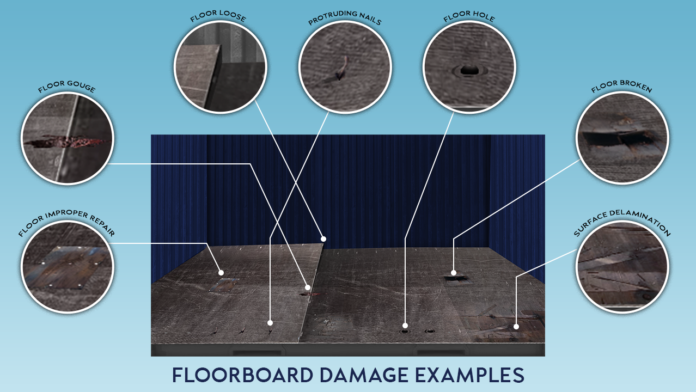

Container Floor Damage Samples

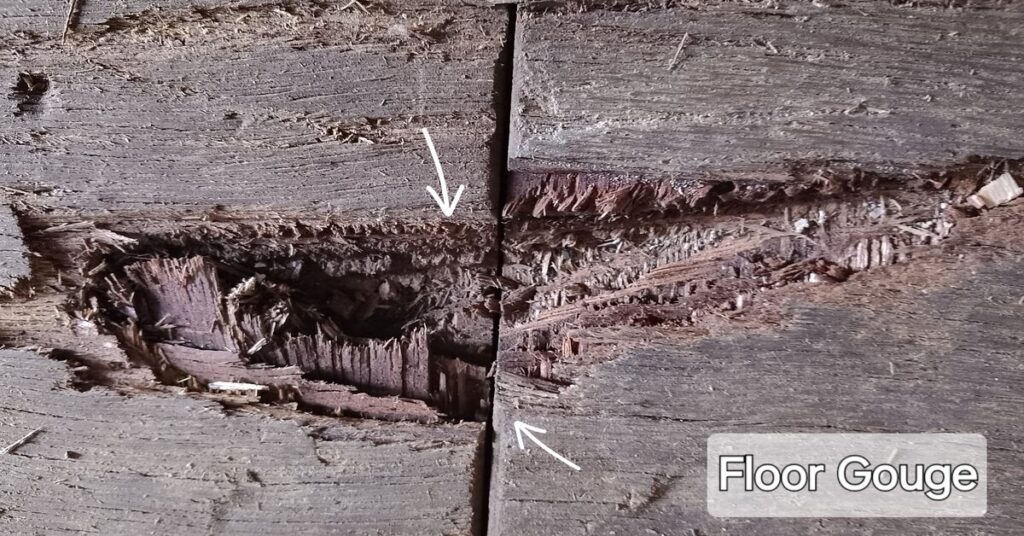

01. Unrepaired ( non repair worthy ) gouge on the interior face of the container floorboards with areas that have loose splinters.

Action : Smooth the rough edges to prevent cargo from getting caught on flooring.

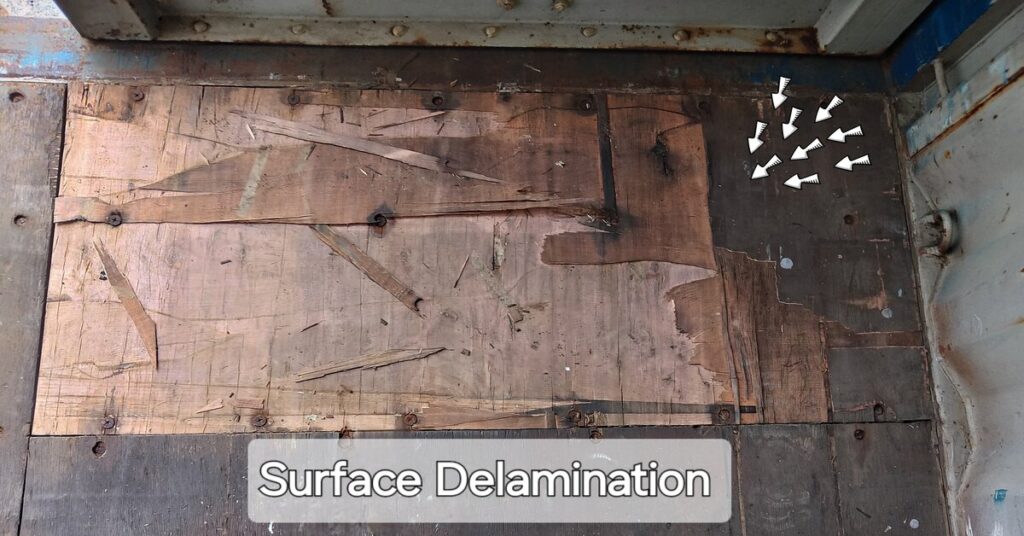

02. Surface delamination of floorboard.

Action : Grind floorboard smooth

03. Finger cracking on underside of flooring (shipping container floorboard finger cracking)

Action : Floorboard section

Finger cracking is considered repairable only if it is accompanied by one or more of the following conditions,

- Visible sign of impact on the opposite side.

- Damage to adjacent components.

- Visible bowing of the opposite side of the floor.

- Hollow sound when hammer tested.

04. Damage & Delaminated floorboard.

Action : Floorboard section

05. Sagging Floorboard between crossmembers (caused by interior delamination of the plywood)

Action : Floorboard section

06. Floor hole with light leaks.

Action : Regardless diameter of hole, repair by install a dowel of floorboard section.

07. Protruding nails on floor

Action : it is accepted when the nail head is flush with surface, if not remove (no action required nail protruding from bottom of floor)

08. Nails holes in container floorboard

Action : if the nail holes leaks light, repair is required – Filling with hard putty or silicone.

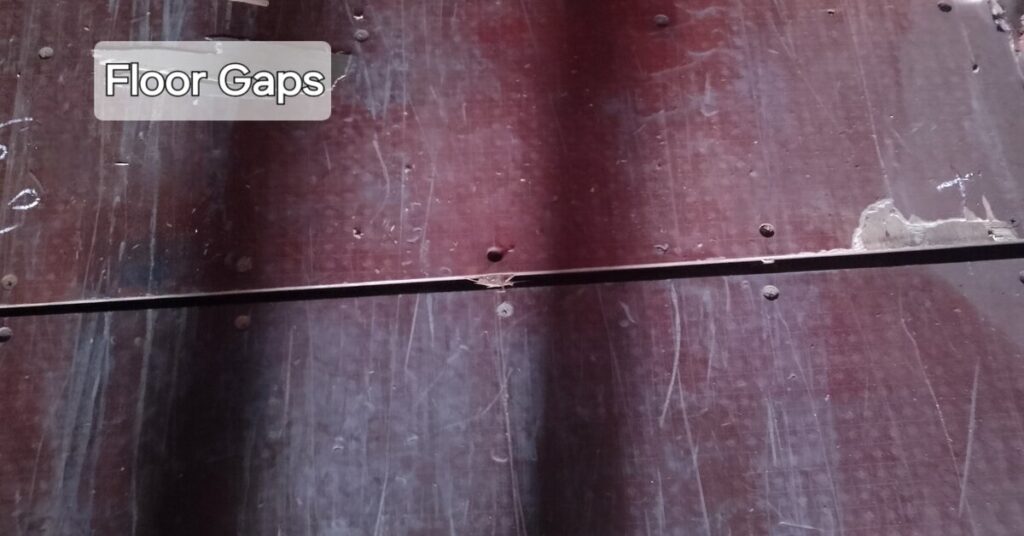

09. Light leakage gaps between floorboard or adjacent components.

Action : floor caulking / apply sealant

10. Downward deformation – if more than 15mm measured transversely at the floor screw centerline.

In situations involving downward deformation, first check the floorboard for any visible signs of impact, fractures, or weakening. Assess the strength of the floorboard as well. If damage is found, appropriate actions like section replacement should be taken. If there’s no visible damage, repairs may be needed on the underlying structural components such as crossmembers, forklift pockets, or outriggers.

Action : In some cases, it might be necessary to temporarily remove the floorboard to repair the underlying components. After completing the repairs, the floorboard should be refitted.

11. Container Floor gouges ( regardless of length ) if more than 15mm or more than 5mm deep throughout a width of more than 150mm.

Action : Some shipping lines, container owners, and leasing companies use wood filler or putty to repair floor gouges. Depending on the owner’s preference, either a floorboard section replacement or applying wood filler is acceptable.

12. Different height of surfaces of adjacent floorboard

Action : Carefully observe floorboard damage, as varying heights can indicate issues like improper repairs, incorrect floorboards, or impact on the underlying structure. Identify the cause and take the appropriate corrective action.

13. Surface Veneer Damage – damage observed down to the 4th ply (top 3 plies are missing + minimum 1 loose ply)

Action : Floorboard Replacement.

14. Steel or any other plates covered on floorboard area’s which done temporary basis. (substandard / improper repair)

Action : floorboard replacement.

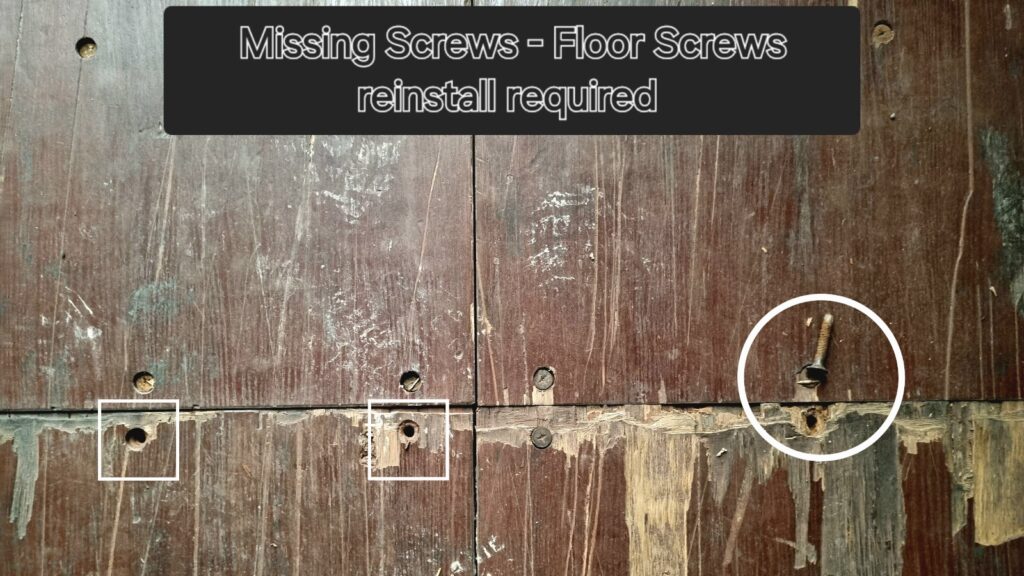

15. Container Floor Loose

Reasons for loose shipping container floors

- Floorboard Wear and Tear: Over time, the plywood or other flooring materials can degrade due to heavy usage, moisture, or impact damage, contributing to loose or unstable floors.

- Corrosion Around Screw Holes: If the steel crossmembers or structure where the screws are mounted are corroded, it can cause screws to loosen, affecting the stability of the floor.

- Enlarged Screw Holes: Repeated stress can enlarge the screw holes, which can cause screws to become loose, no longer securely holding the floorboards in place.

- Floorboard Swelling or Shrinking: Changes in moisture levels can cause the plywood to swell or shrink, which may also loosen screws or cause the flooring to become unstable.

Action : Floor screws refit or apply new floor screws (reinstalled).

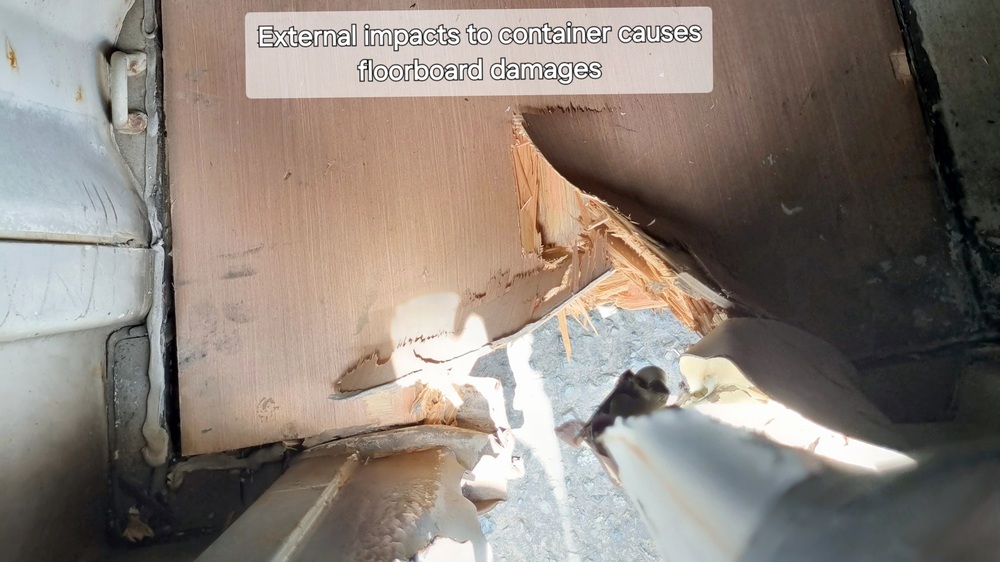

16. External impacts to container causes floorboard damage

Action : Floorboard replacement or floorboard section

Read this to understand ” How Shipping Container Damages Occur in Container Yards ”

17. Floor oil stains, sticky or glue, tar on the floorboard

Action : Scrape or Power Sanding

18. Oil-absorbed floorboard

A fully oil-soaked floor often shows wet oil on the surface with oil underneath and possible leakage, which can harm the cargo.

Action : Floorboard section or Floorboard replacement